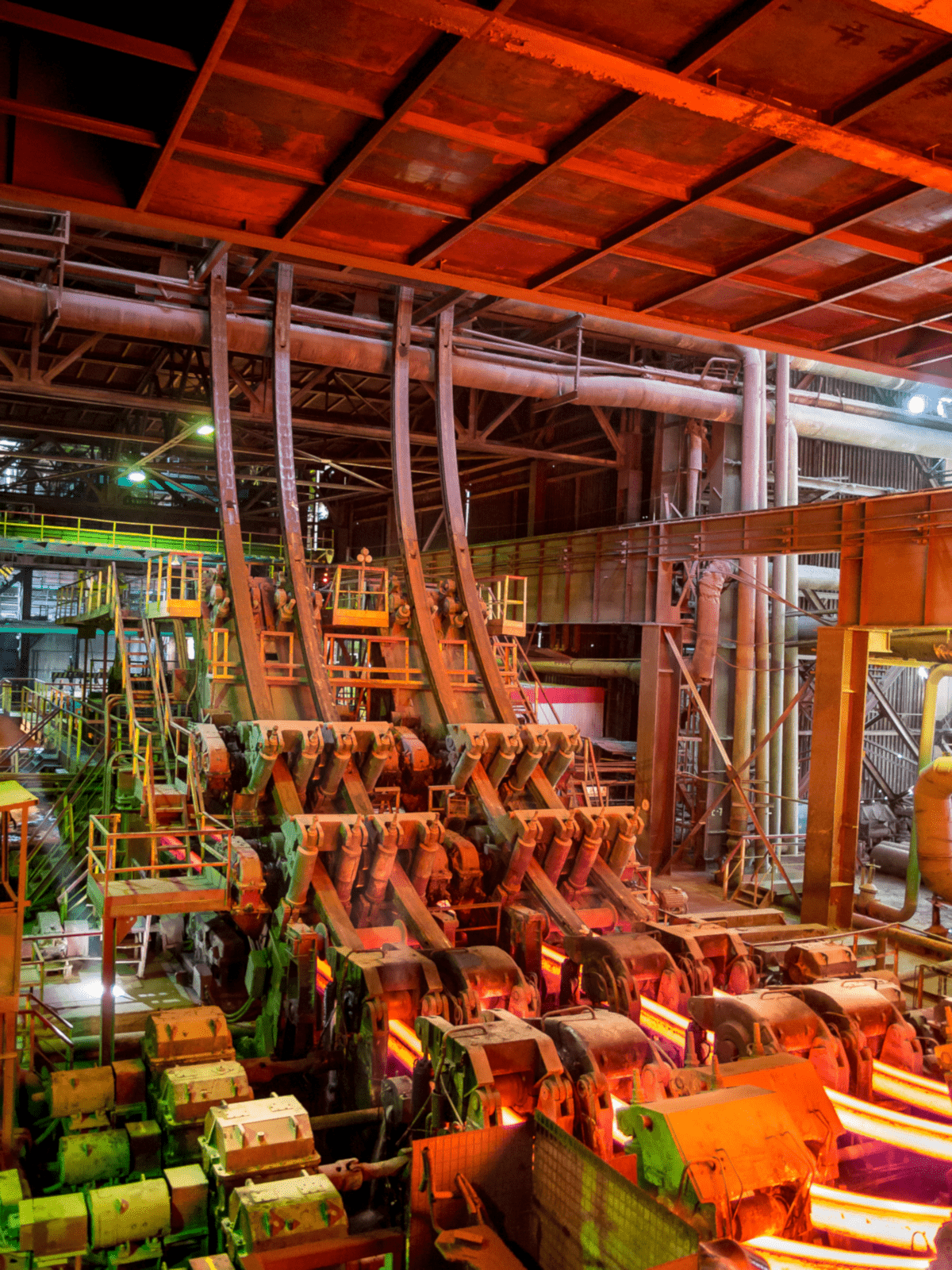

Advanced continuously cast high strength low alloy steels are often subject to elemental segregation along the billet or slab centerline during casting and cooling. Monitoring macrosegregation is critical before billet or slab rolling and forming, for if elemental segregation is excessive it can lead to structural weakness, including cracking and breaking of rolled and formed products. Hence, by catching macrosegregation before rolling and forming can save substantially in production costs and material handling and product remelting and casting.

Traditional industry monitoring has been done by etching and optical imaging. This is time consuming and not compositionally quantitative. Results are subjective and difficult to compare if methods and sample preparation are not identical between plants and different steel manufacturers. Etching is subjective and cannot provide quantitative compositional data for meaningful statistical analysis, but can provide information about structural homogeneity.

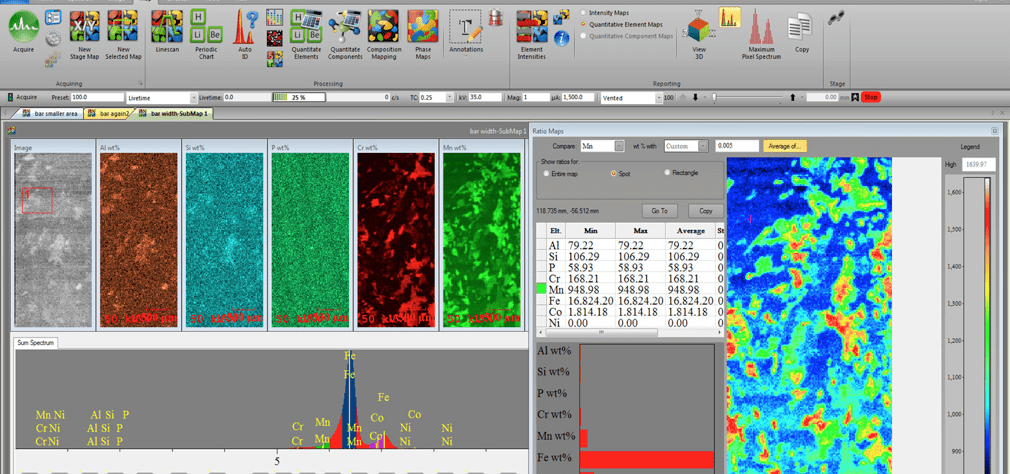

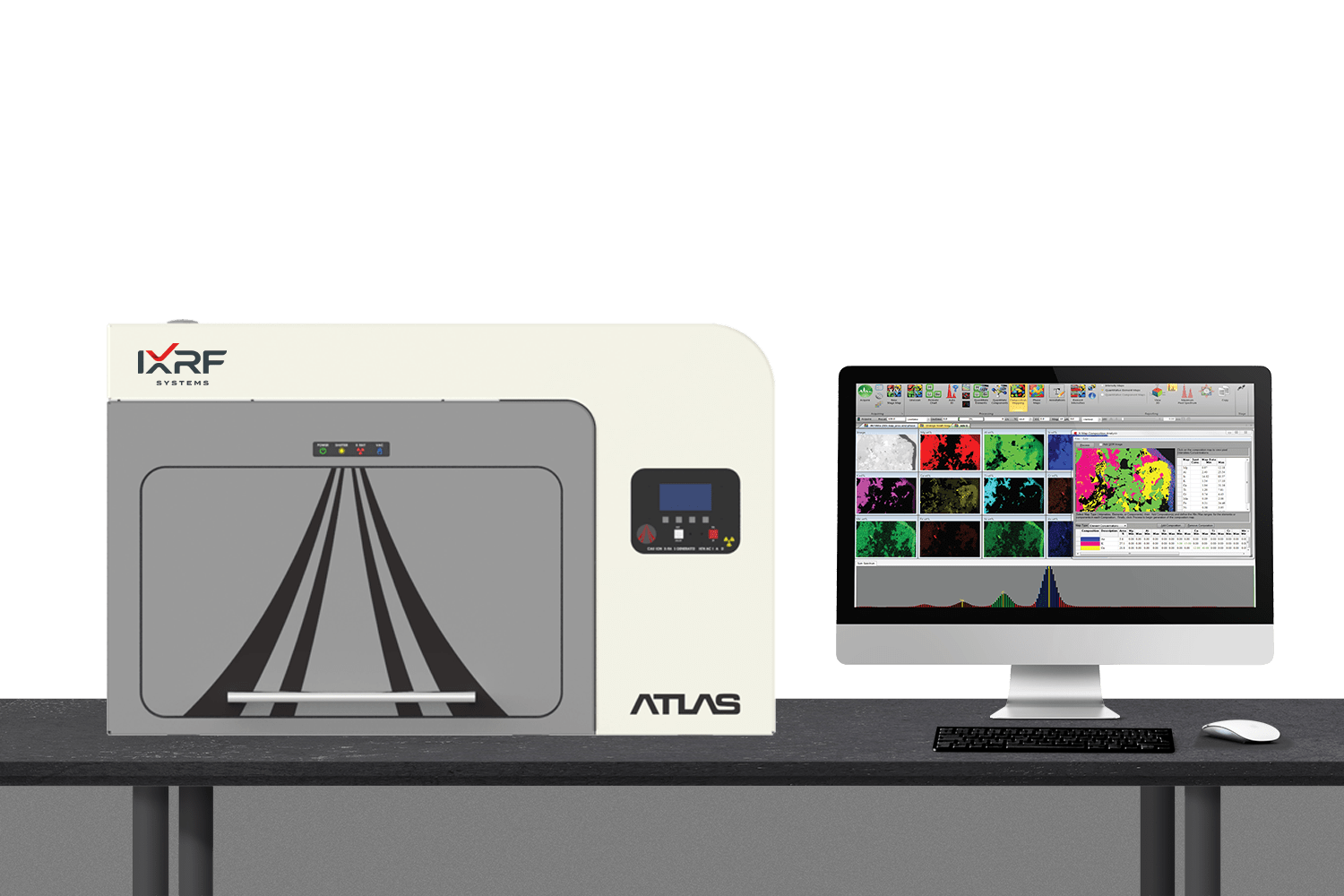

Now, by employing IXRF Systems’ advanced mapping, micro-spot energy dispersive X-ray fluorescence (microEDXRF) spectroscopy, it is possible to rapidly scan centerline areas and quantitatively monitor elemental inhomogeneity. Sample preparation is simple, only a clean milled surface is required, and pixel concentrations less than one-tenth of a weight percent can be measured and mapped. The pixel size can be varied, as the focused X-ray source can produce beam diameters from 5 to over 100 microns, ideal for rapidly mapping macrosegregation from tens to hundreds of microns. With the X-ray source normal to the sample surface, the exciting area is round and multiple detectors, up to four, can be used to measure higher count rates. Map data files can contain as many as 5 GB or more.

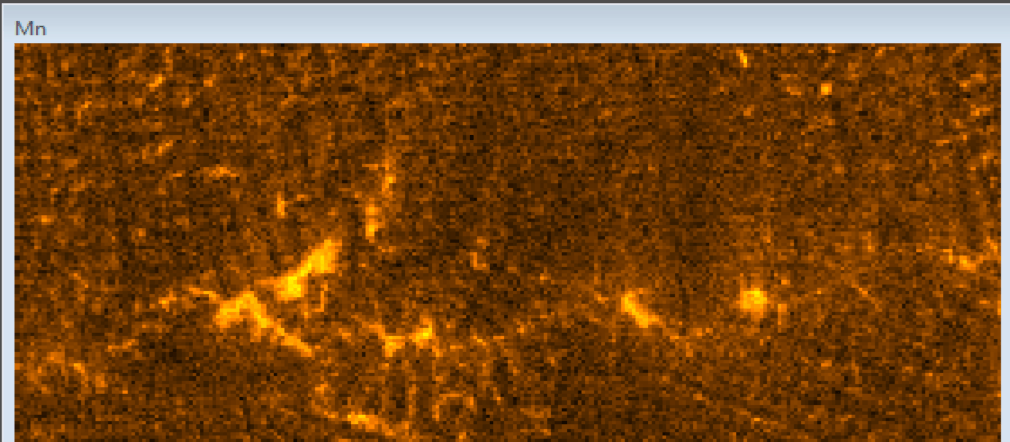

While many key elements co-segregate in continuously cast high-strength steels, of particular interest is manganese (Mn) which is the primary hardening agent that can easily be measured in an air environment. Other segregating elements of interest include Cr, Ni, Mo, S, P, Al, and Si.

The ATLAS not only provides visual evidence of macro segregation in elemental maps but quantitative measurement of elemental concentrations in the centerline region of continuously cast billets and slabs.

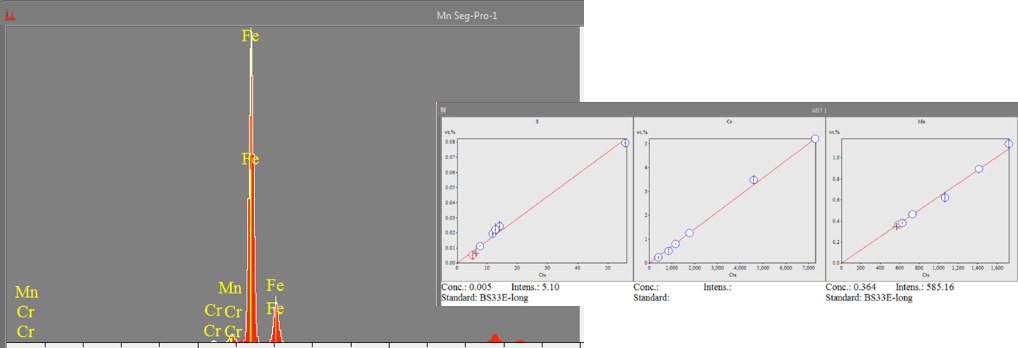

Quantifying segregating element concentrations is determined against a range of reference steel standards using linear regression, providing accurate quantitative results. Typical calibration curves for different segregating elements of interest are displayed below.

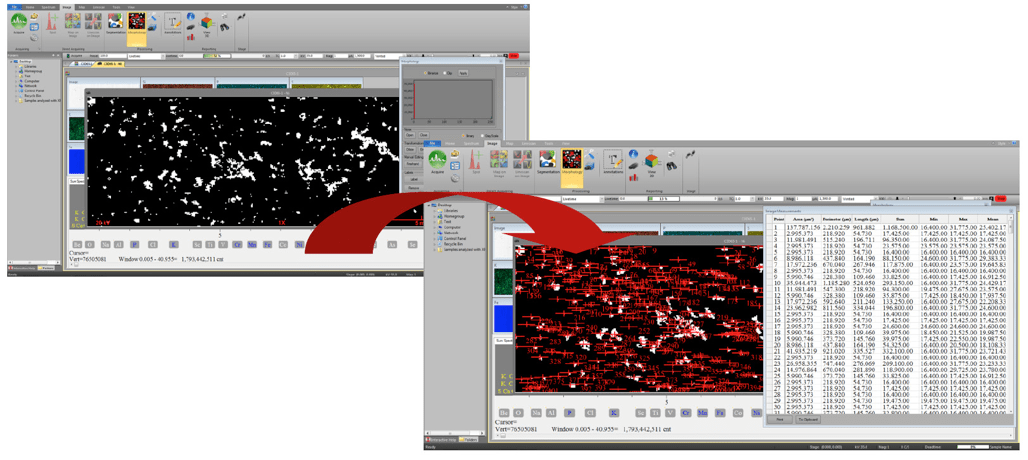

X-ray elemental maps can also be used to identify and study in greater detail inhomogeneity problems in steels and other materials, natural and manufactured, such as inclusions and impurities. Atlas can automatically identify and quantify impurities and inclusions within a map.

The versatile ATLAS mapping software and automated stage control enable unique rapid return on command to map locations of interest with exacting stage relocation precision (one micron). This unique on-command “Go-to” feature can rapidly drive the stage to any area of interest, inclusion, or inhomogeneity for further detailed study and/or to confirm initial mapping results. This capability provides corroboration of initial mapping results and the ability to refine mapping results in greater detail if needed or desired. The IXRF Atlas system provides a game-changing non-destructive capability for monitoring the homogeneity of natural and manmade materials and how it can affect some of their chemical and structural properties.

See AIST July 2017 Iron and Steel Technology article “Bridging the Gap: MXRF Technique Rapidly Maps Centerline Segregation” by Joydeep Singupta and Jackie Leung, ArcelorMittal Global R&D―Hamilton, Ontario, Canada and K. Witherspoon, IXRF Systems, Inc. Austin, TX for technical details about the advantages of the μXRF technique for quantitative macrosegregation monitoring.

Now, by employing new advanced scanning micro x-ray energy dispersive spectroscopy technology, it is possible to rapidly scan centerline areas and quantitatively monitor elemental inhomogeneity. Sample preparation is simple, only a clean milled surface is required, and pixel concentrations less than one-tenth of a weight percent can be measured and mapped. The pixel size can be varied, as the focused X-ray source can produce beam diameters from 5 to over 100 microns, ideal for rapidly mapping macrosegregation from tens to hundreds of microns. With the X-ray source normal to the sample surface, the exciting area is round and multiple detectors, up to four, can be used to measure higher count rates. Map data files can contain as many as 5 GB or more.

The ATLAS series of micro X-ray fluorescence (μXRF) spectrometer systems leads the industry in analytical capabilities:

- Focused X-ray source from 5 to 100μm

- Measure from Na through U in air, vacuum, or helium

- Largest sample stage with the most complete chamber options

- High-speed slew scanning at 1-3ms/pixel with < 1-micron precision on all axes

- X-ray source normal to sample surface with multiple detector geometry

- Optimized optical viewing system

- 3 sample positioning and analysis cameras

- Versatile quantitative software

- Standardless bulk analysis FP software

- Linear regression

- Quantitative line scan and mapping

- Thin film and coatings metrology

- Go To Feature―go to any pixel region in the map on command to reanalyze

- Fully automated instrument control of all parameters

- High-resolution SDD detector options with active areas from 30 to 150mm2