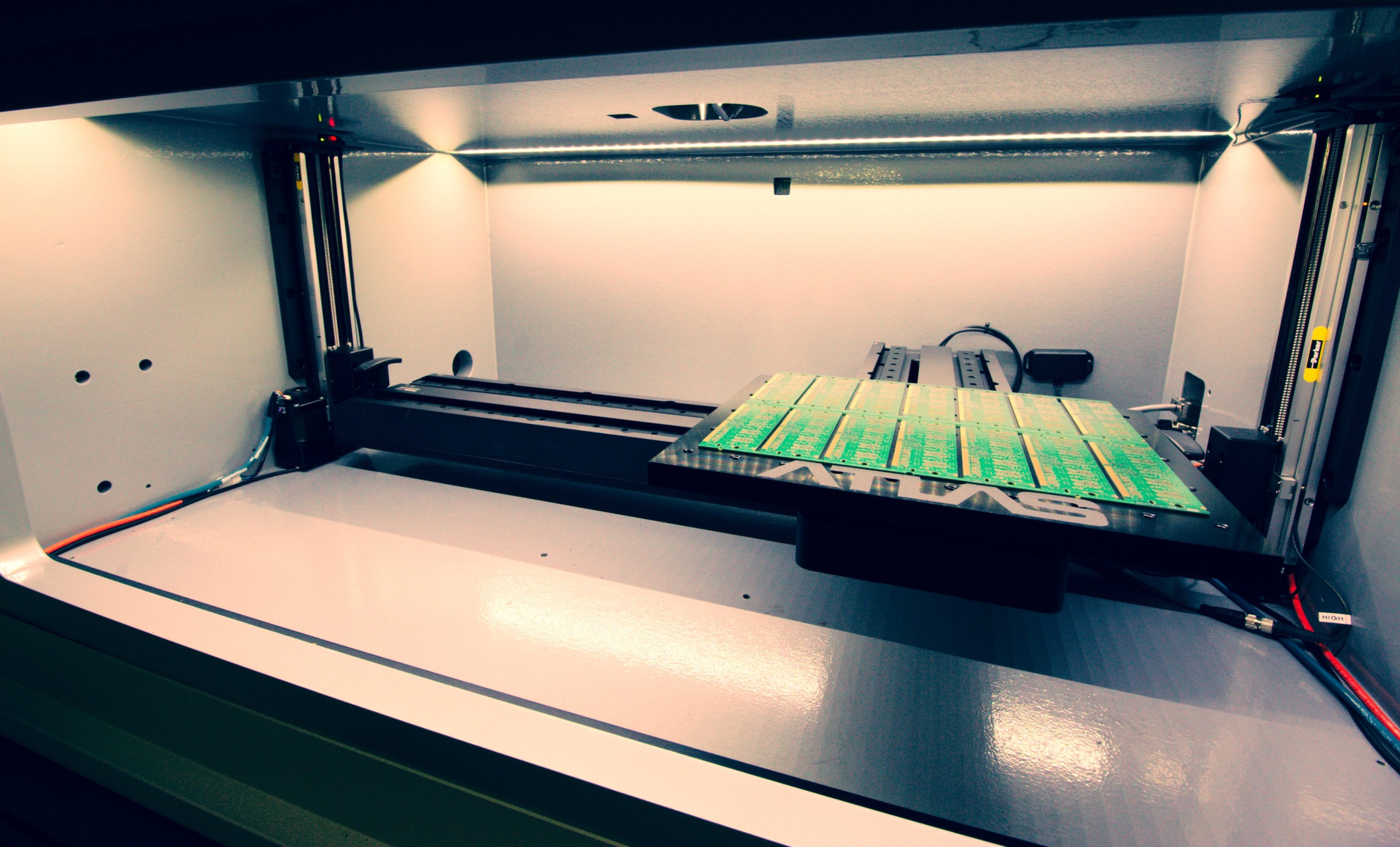

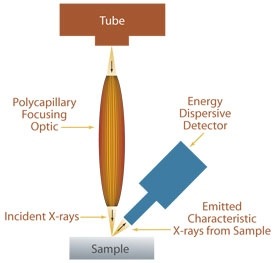

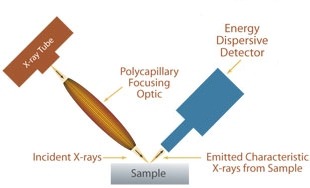

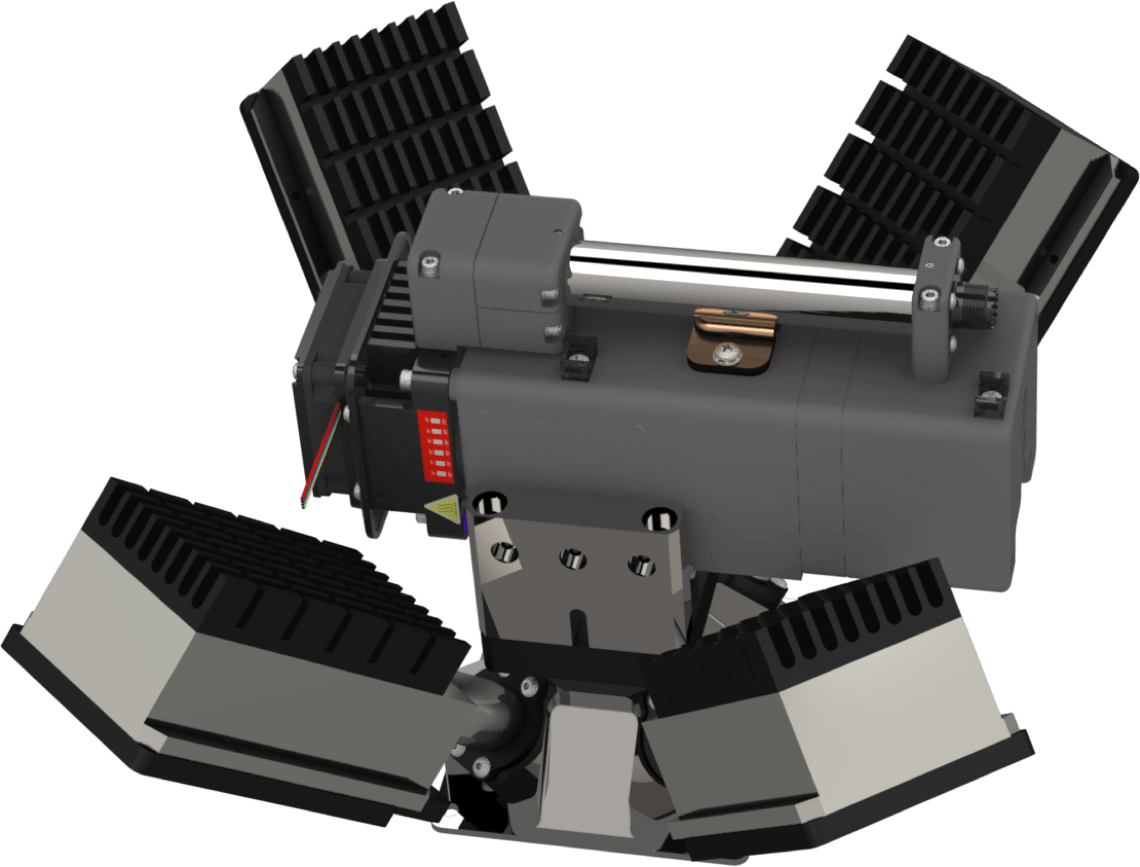

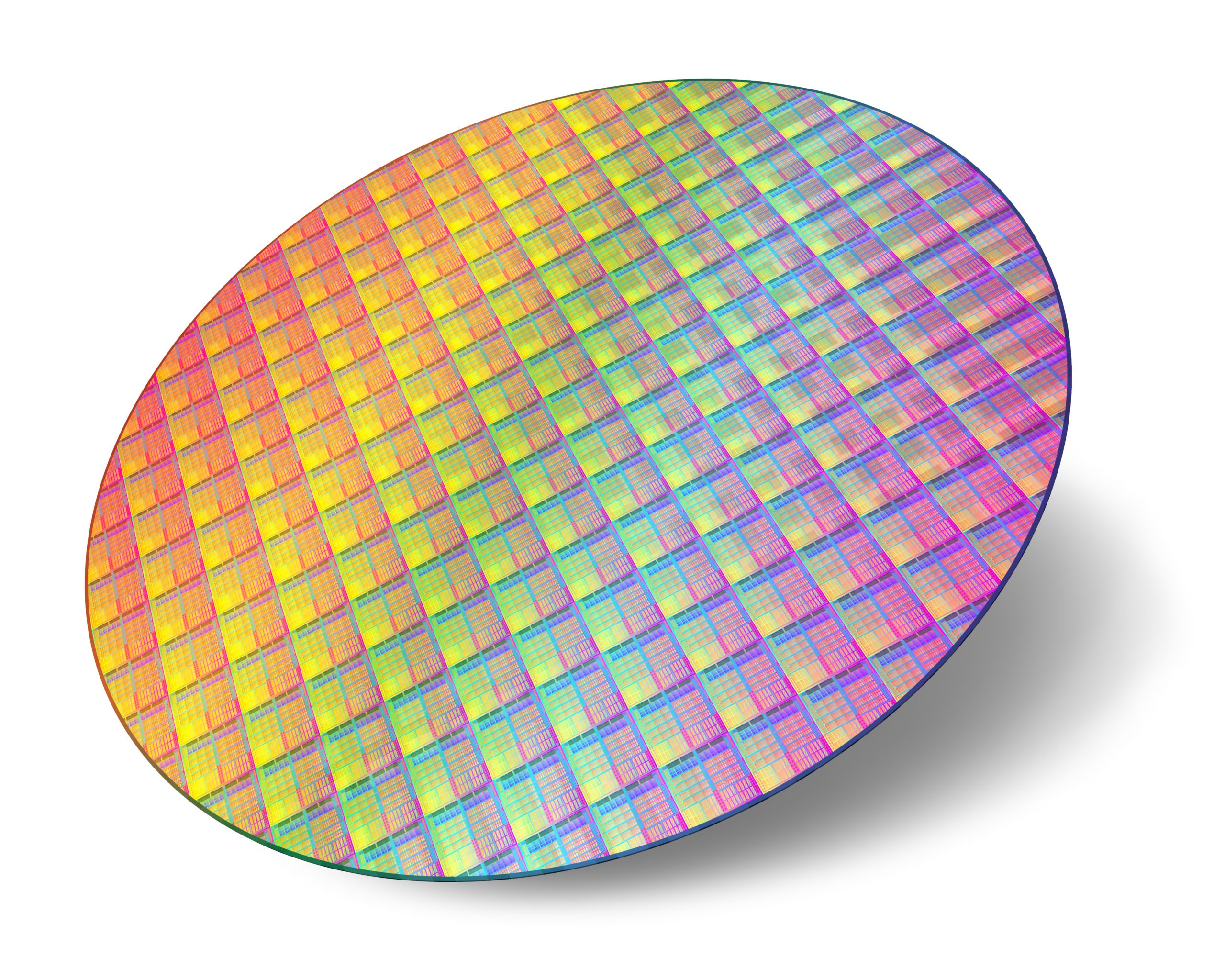

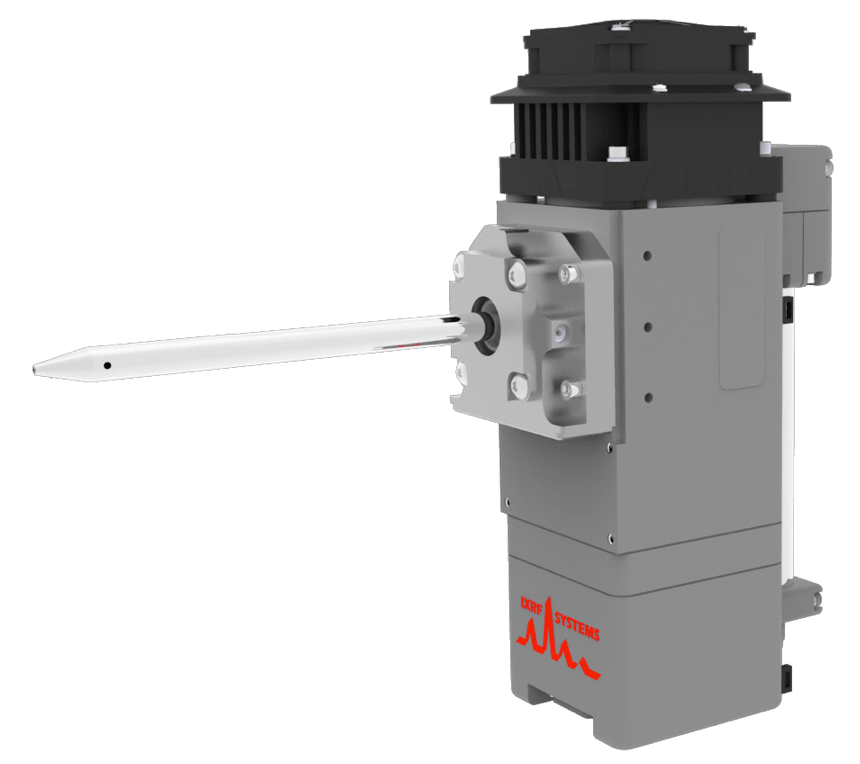

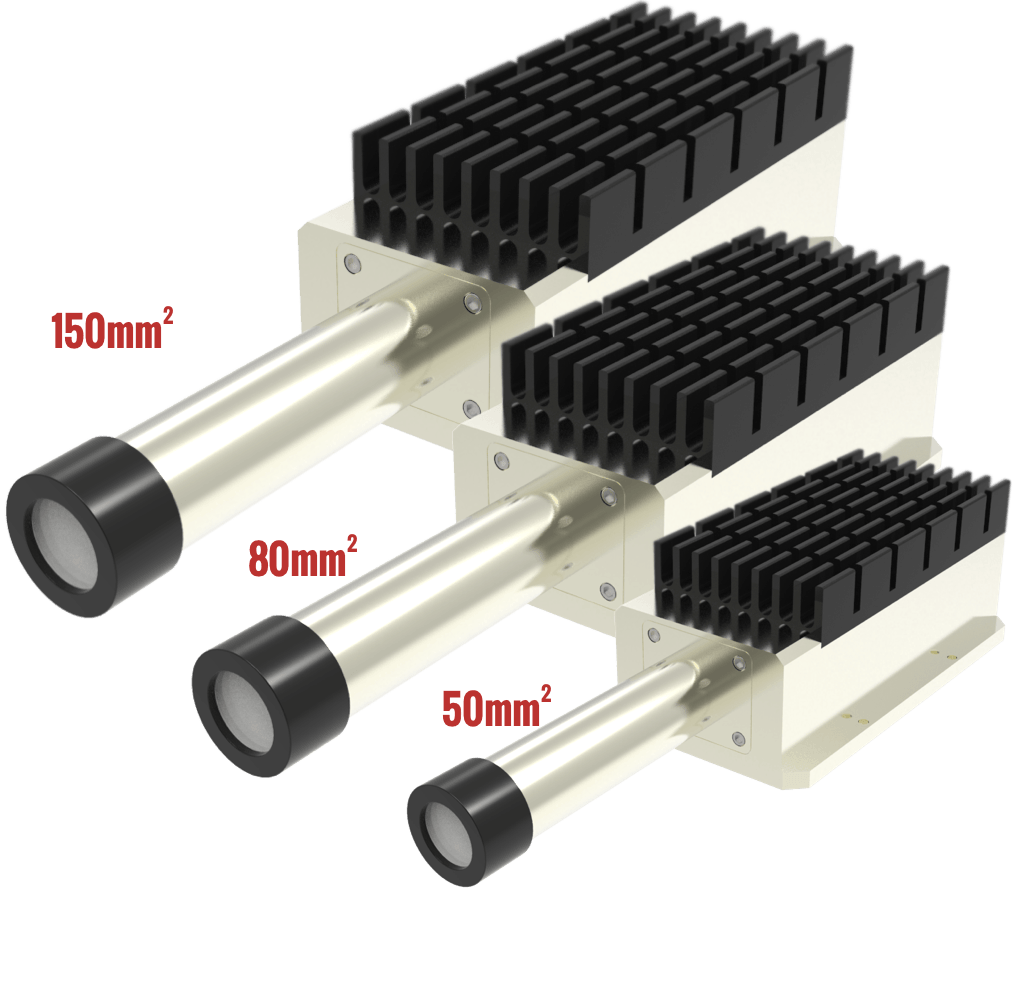

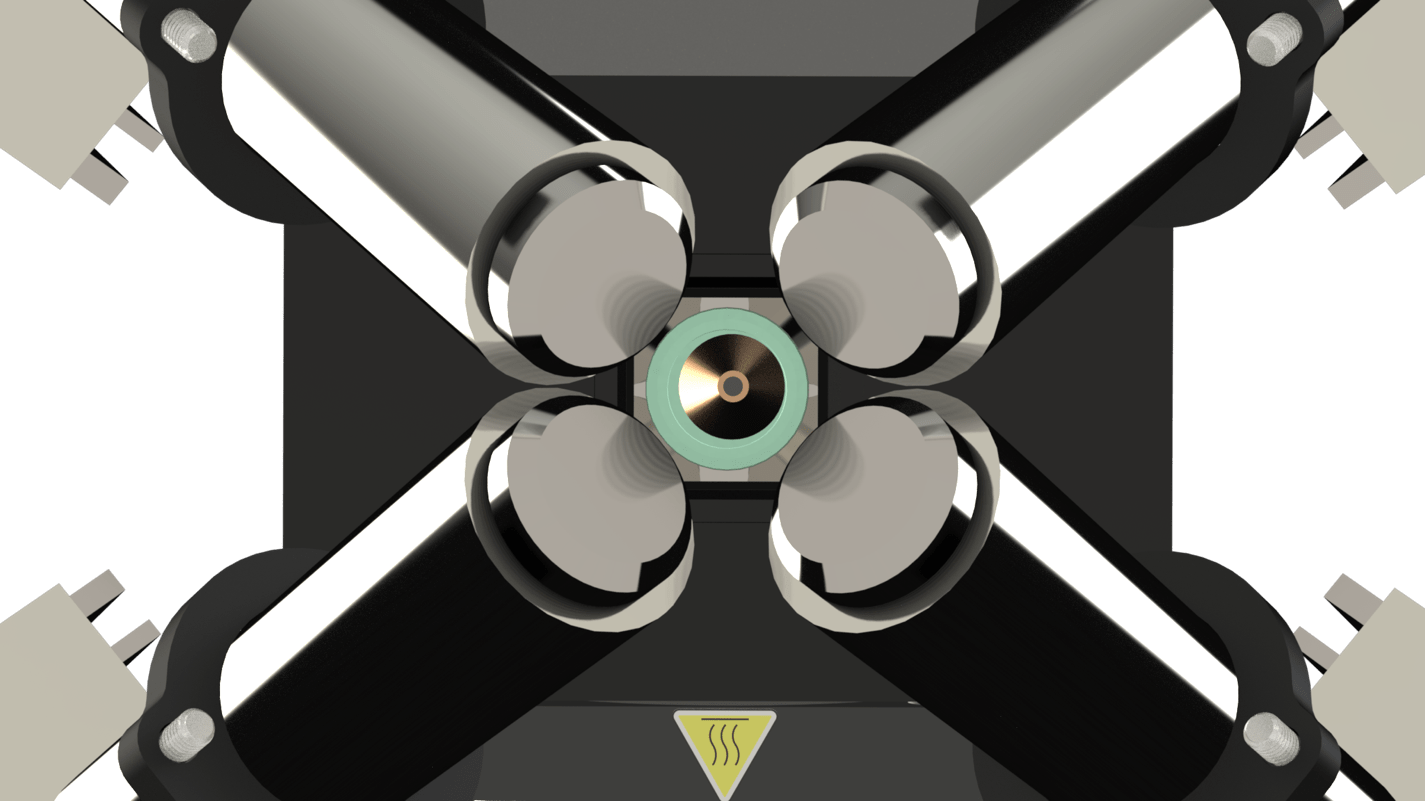

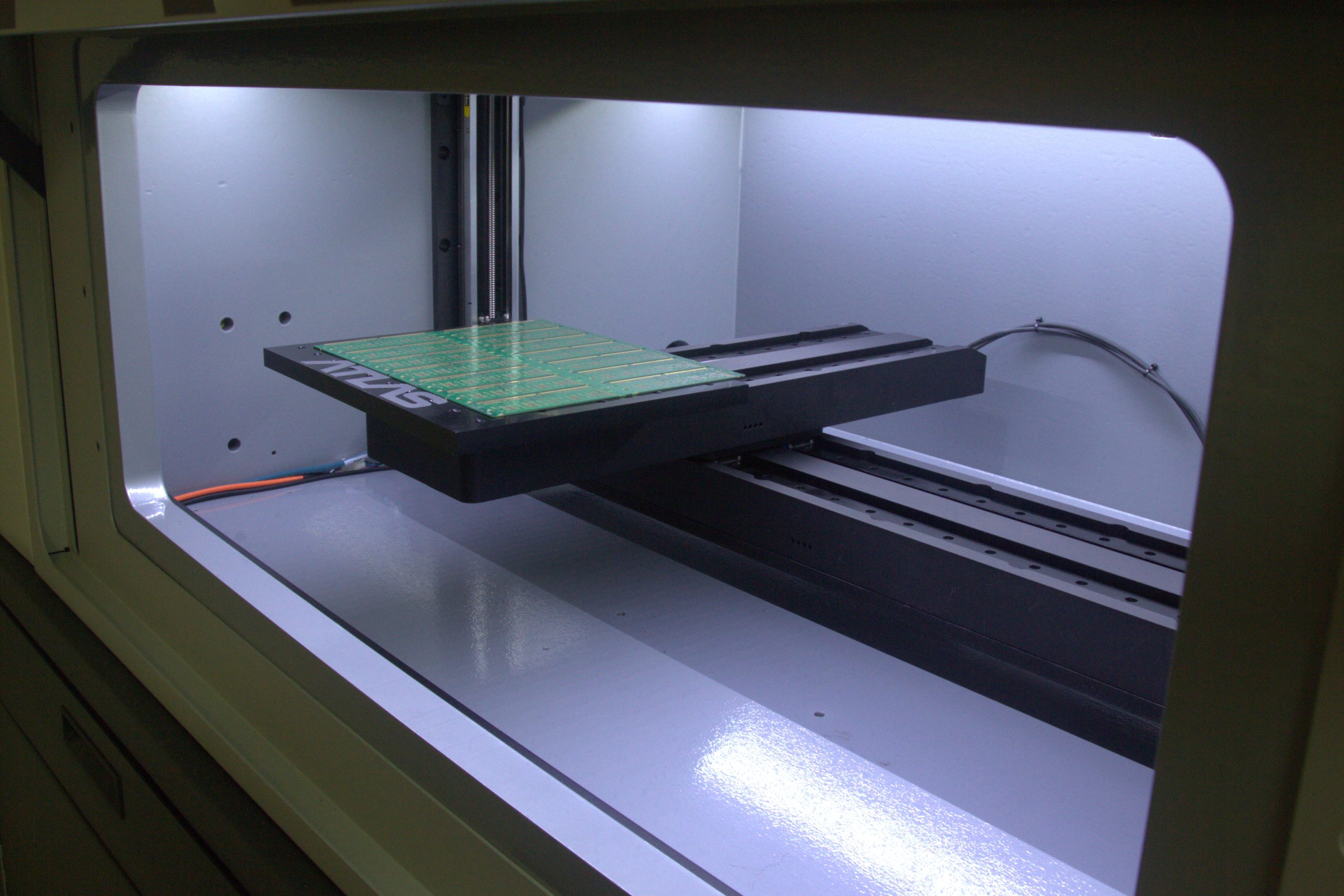

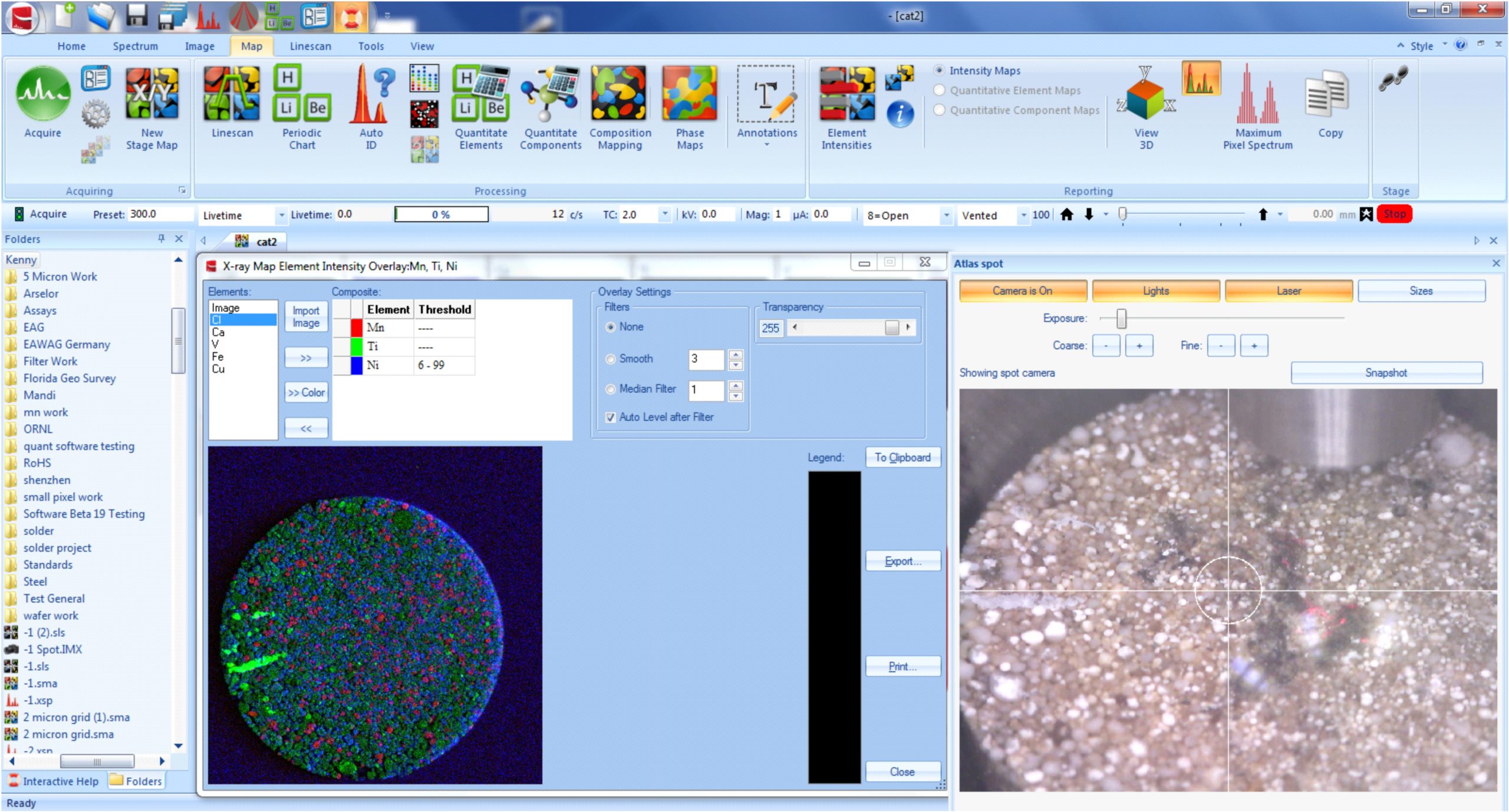

IXRF Systems’ ATLAS SEMI is the very latest micro spot energy dispersive X-ray fluorescence (micro XRF) imaging spectrometer for semiconductor metrology. Designed to image and analyze (edge-to-edge) wafers up to 300 mm diameter, ATLAS leads the industry in virtually every major specification category from the largest chamber and the highest detector active area, to the longest mapping travel and smallest X-ray micro-spot.

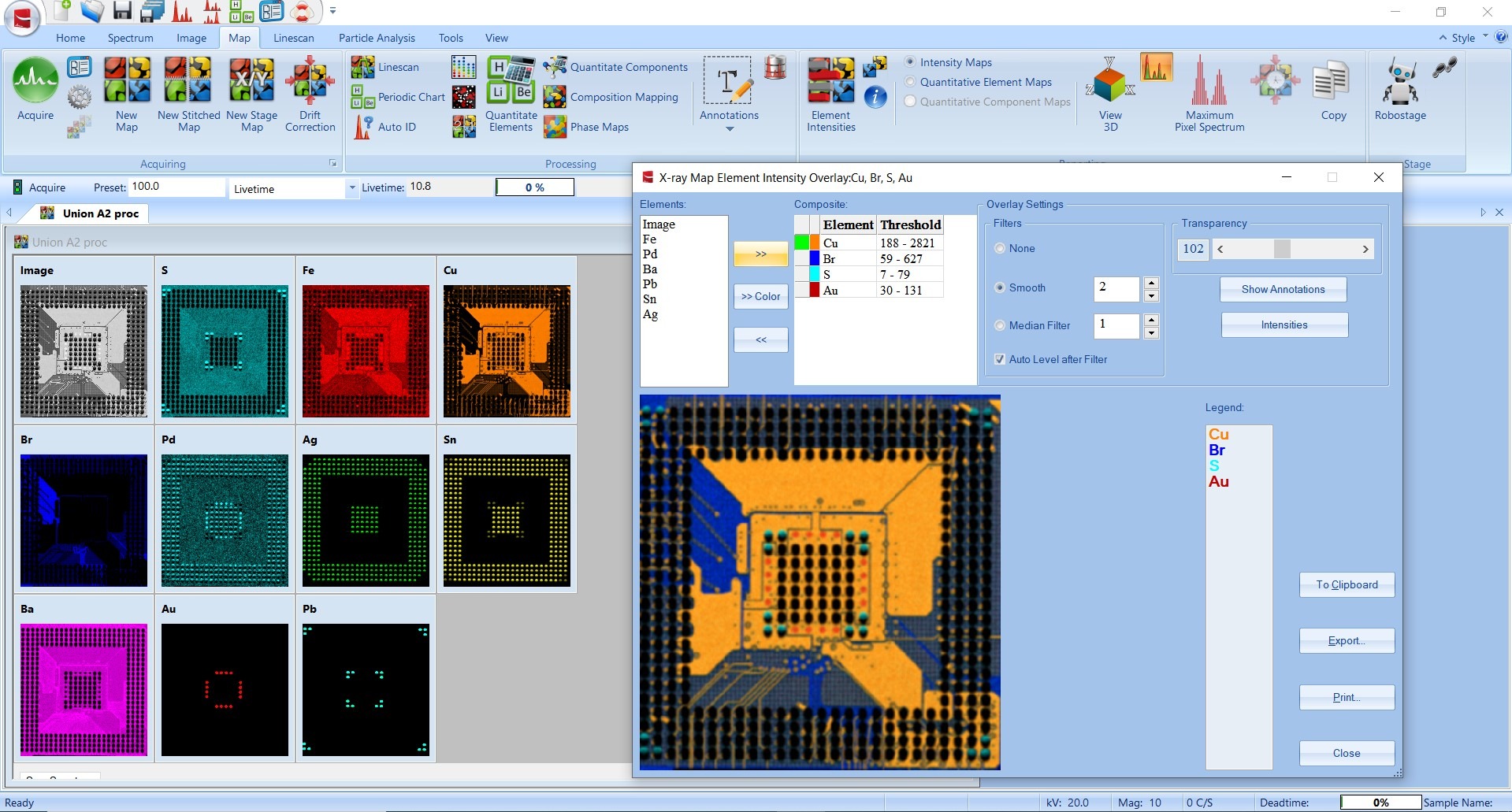

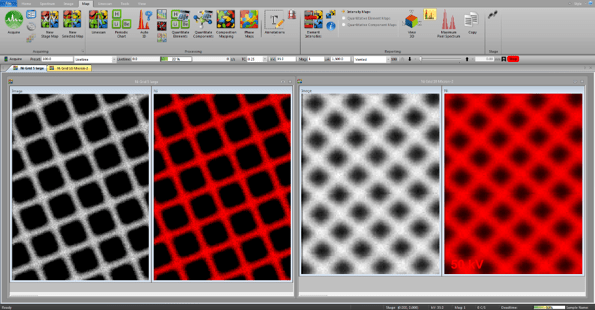

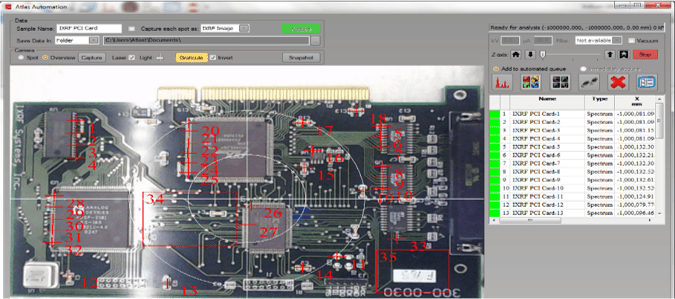

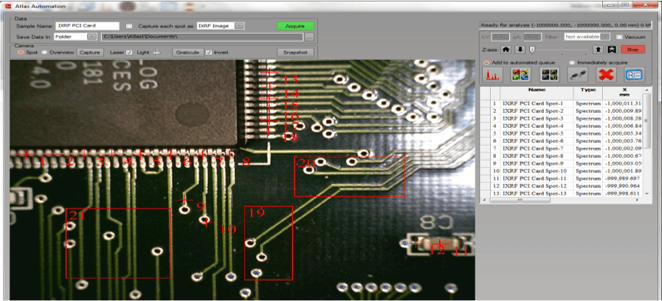

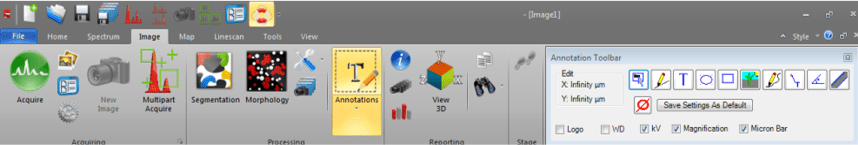

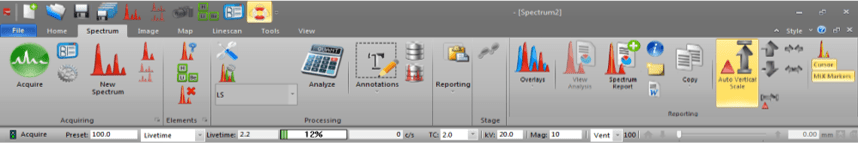

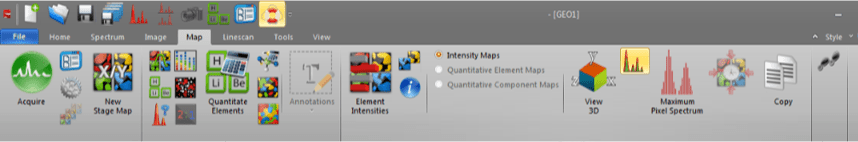

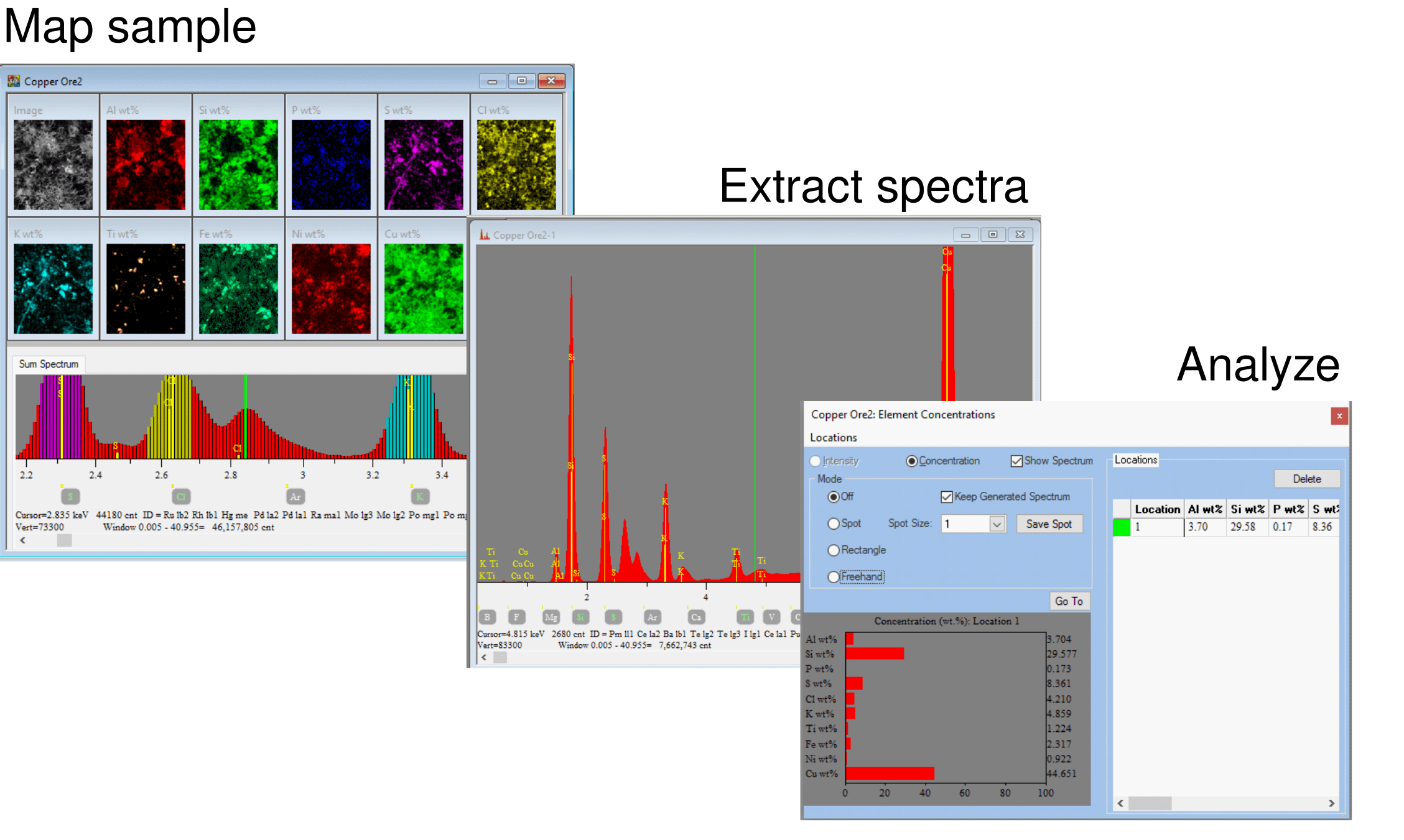

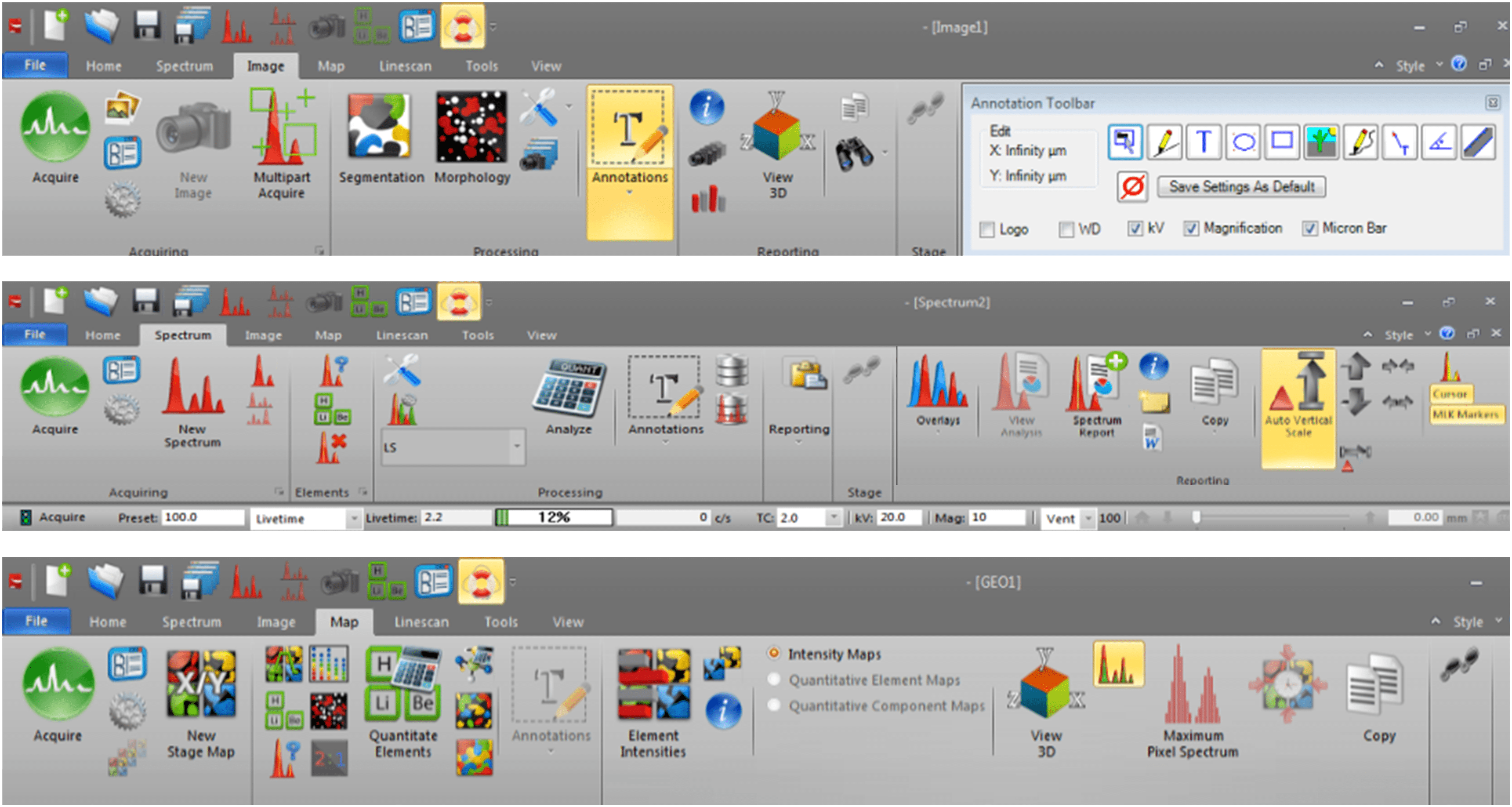

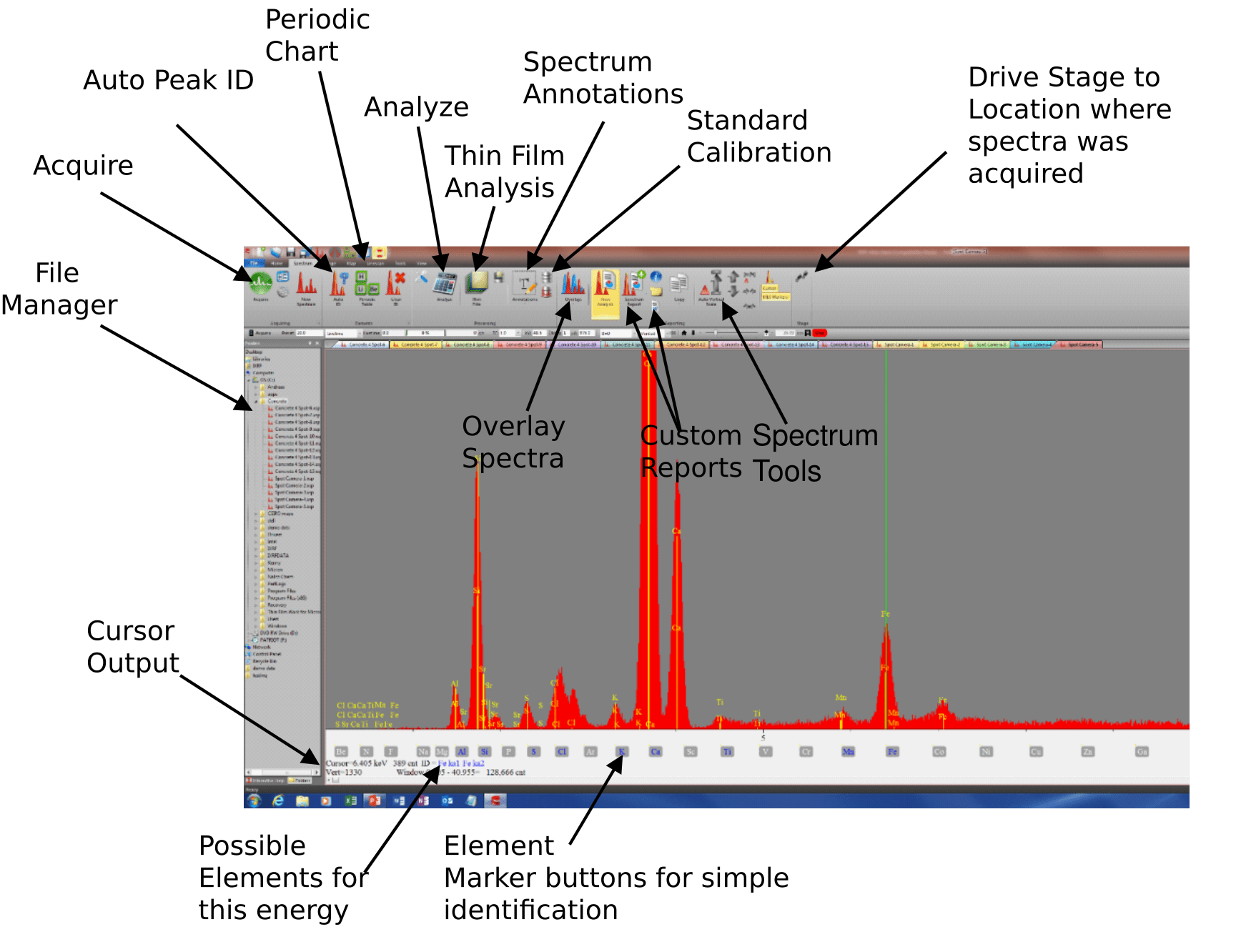

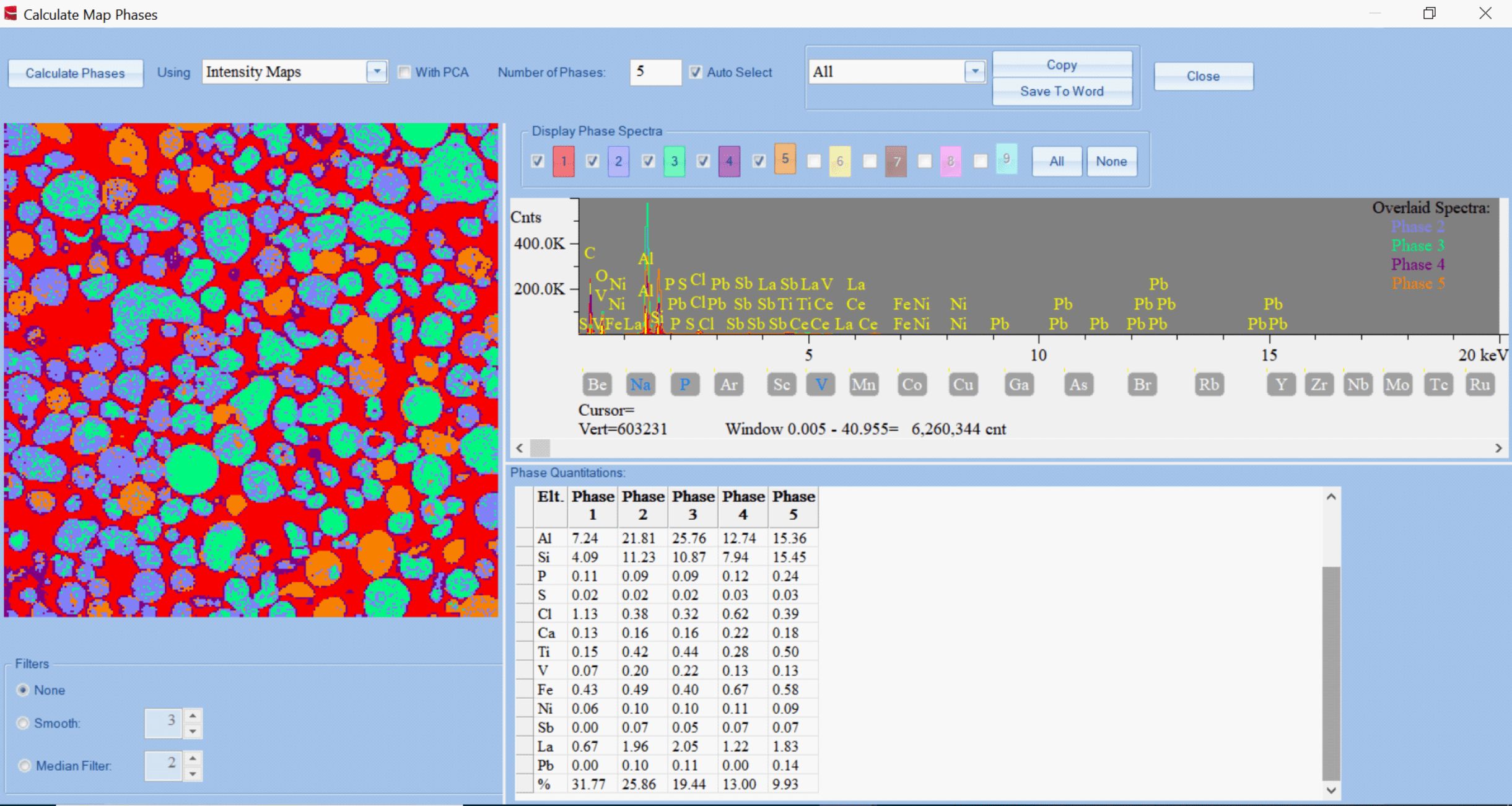

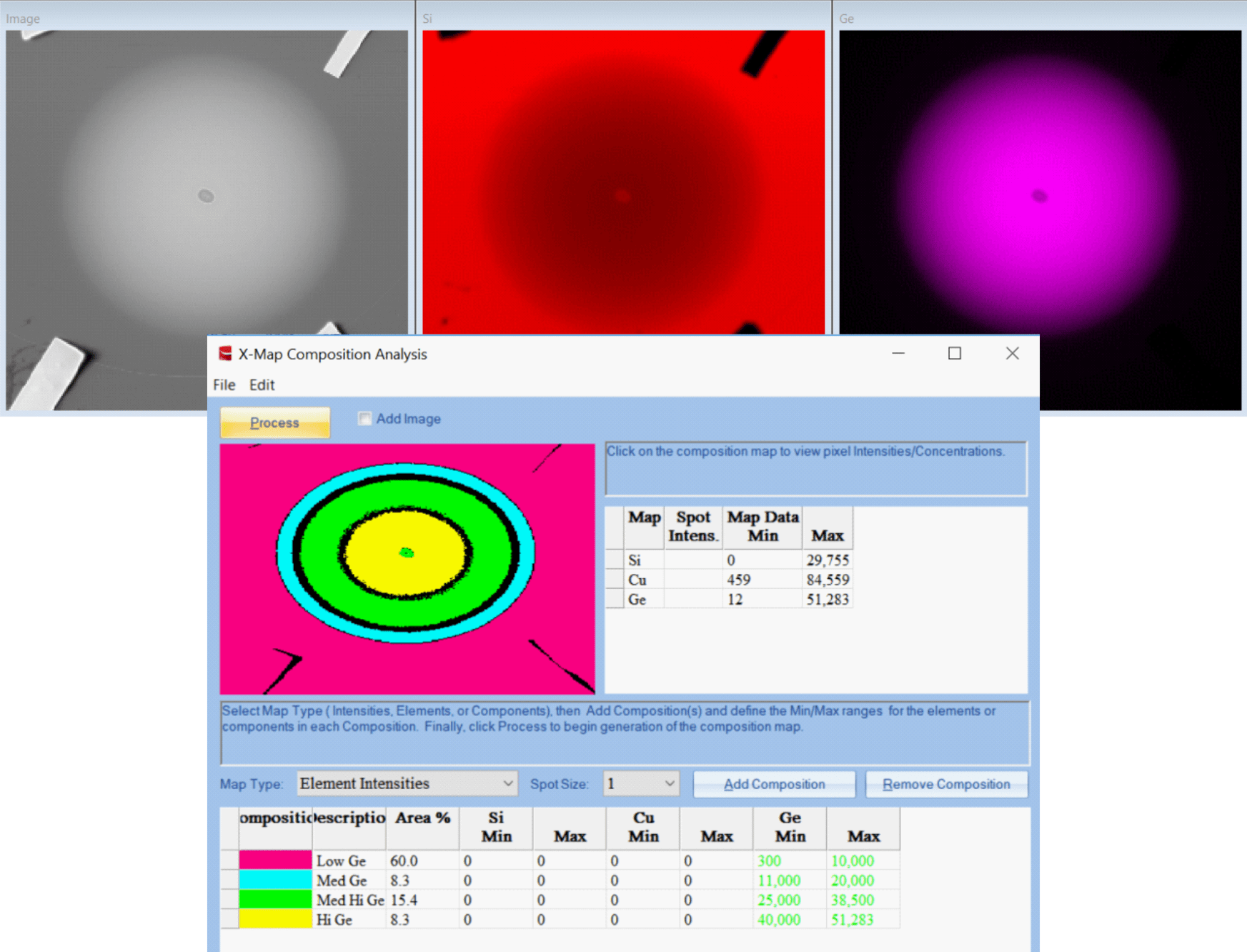

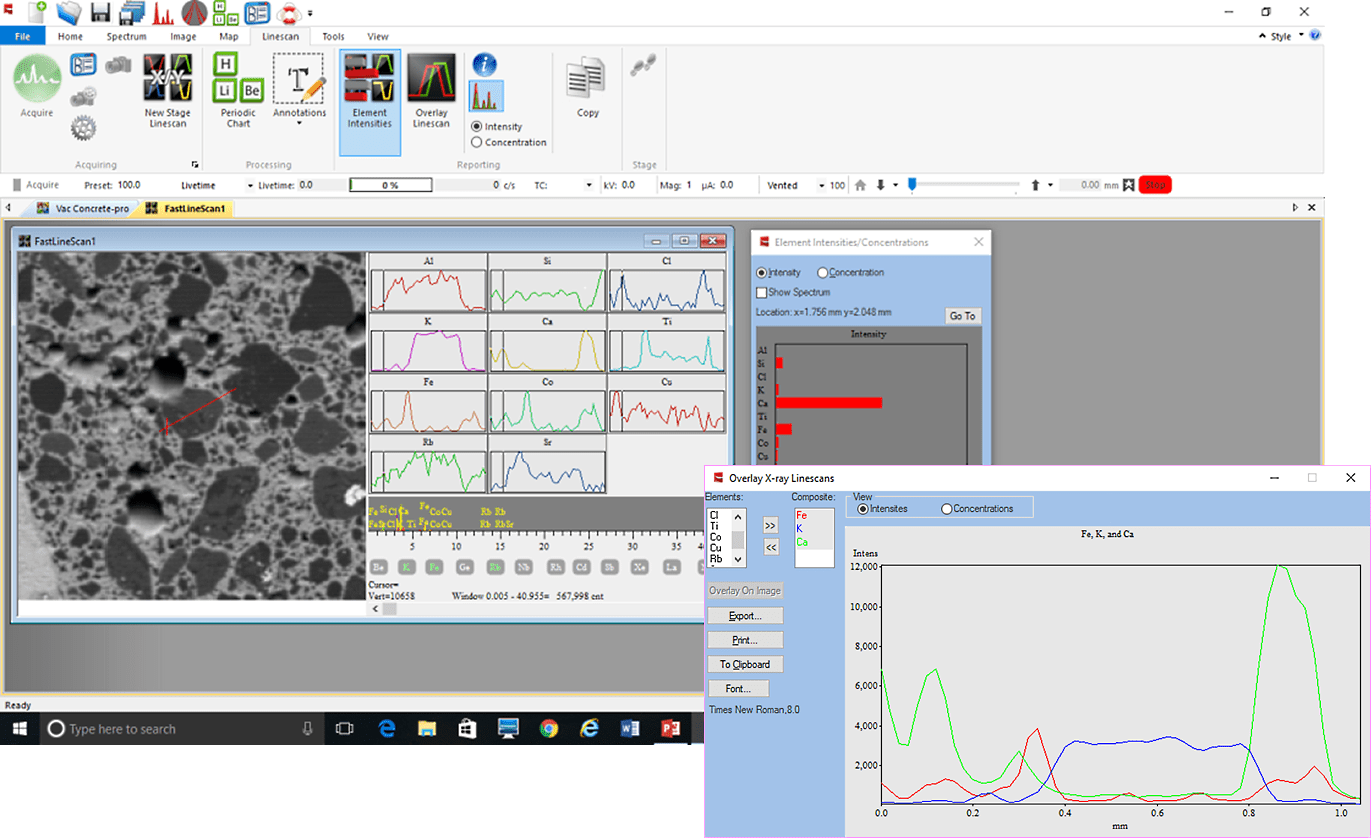

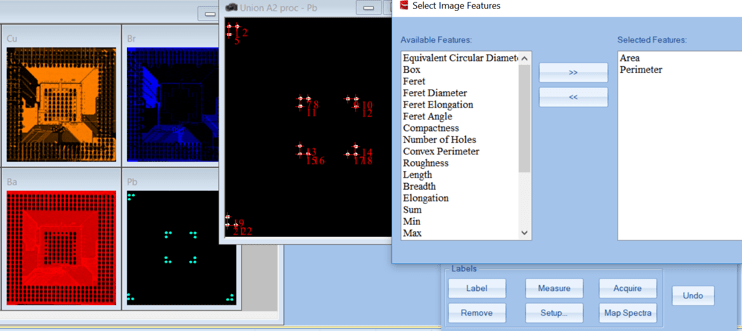

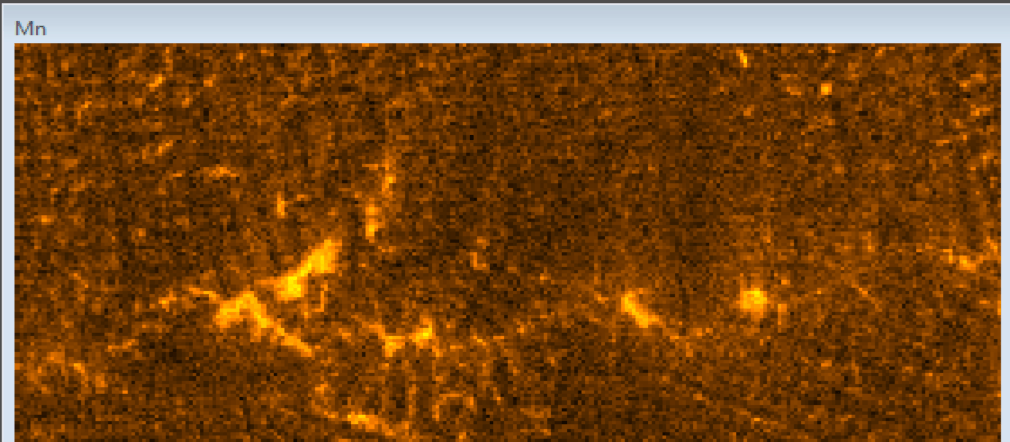

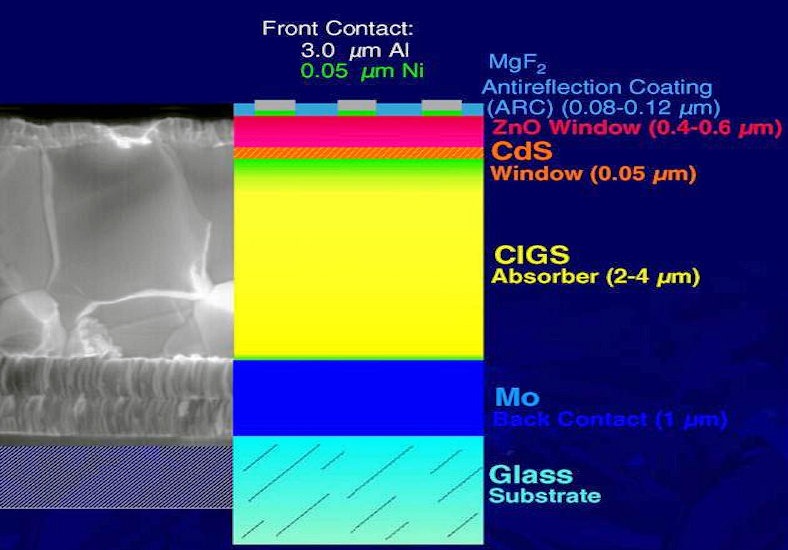

Hardware specifications are only half of the ATLAS Advantage™. ATLAS’ Iridium Ultra software platform, developed with SEM-EDS elemental mapping and analytical functionality, is unsurpassed in it’s ability to provide elemental and phase mapping, line scans, critical dimensions (CD) as well as qualitative and quantitative elemental analyses of multi-layer thin film stacks. The functional, flexible, and feature-rich software suite guarantees unprecedented productivity. ATLAS SEMI is the micro XRF metrology tool that leads with innovation.