🔩 TL;DR

The ProSA meso-XRF analyzer quickly maps elemental distribution—like Mn, Si, S, and P—across steel slab centerlines to detect segregation not visible through etching. By generating high-resolution elemental datacubes, it supports automated monitoring and consistent process control. This helps manufacturers produce stronger, more uniform steel, especially in high-strength and HSLA applications.

Introduction

In today’s competitive environment, steelmakers must do more than meet specifications—they must consistently exceed expectations. This is especially true for Advanced High-Strength Steels (AHSS) and High-Strength Low-Alloy (HSLA) steels, where internal quality significantly impacts downstream performance. One of the most stubborn and costly defects in steel slabs is centerline segregation—a condition where alloying elements concentrate along the centerline of the slab during solidification.

Until now, internal slab quality assessment has relied heavily on destructive, time-consuming techniques such as etching and visual grading. These methods are slow, subjective, and provide limited feedback for immediate process improvement.

That’s why IXRF Systems, in partnership with ArcelorMittal Global R&D, developed and introduced the Prometheus Segregation Analyzer (ProSA)—a breakthrough showcased at the AISTech 2025 conference in Nashville. At IXRF Systems, we believe there’s a better way to assess internal slab quality—one that’s faster, more accurate, and entirely non-destructive. ProSA is the world’s first industrial-scale XRF device capable of performing at-line, quantitative analysis of slab centerline segregation, without cutting, etching, or subjective visual grading. By eliminating laborious sample preparation and delivering rapid elemental mapping data, ProSA is redefining quality assurance from the caster to the customer.

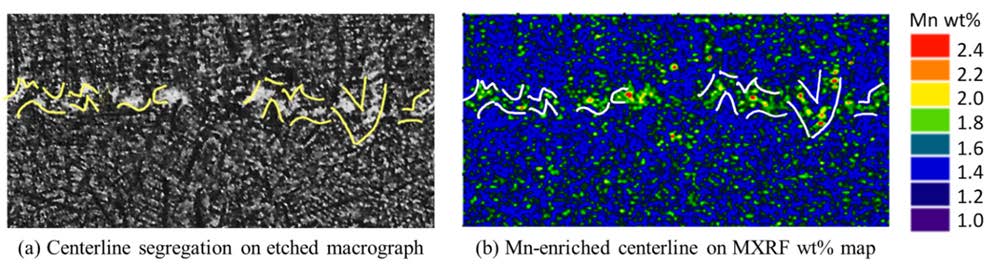

Figure 1: The Prometheus Segregation Analyzer (ProSA), an at-line EDXRF system for non-destructive mapping of elemental segregation in steel slabs.

From Lab to Line: The ProSA Advantage

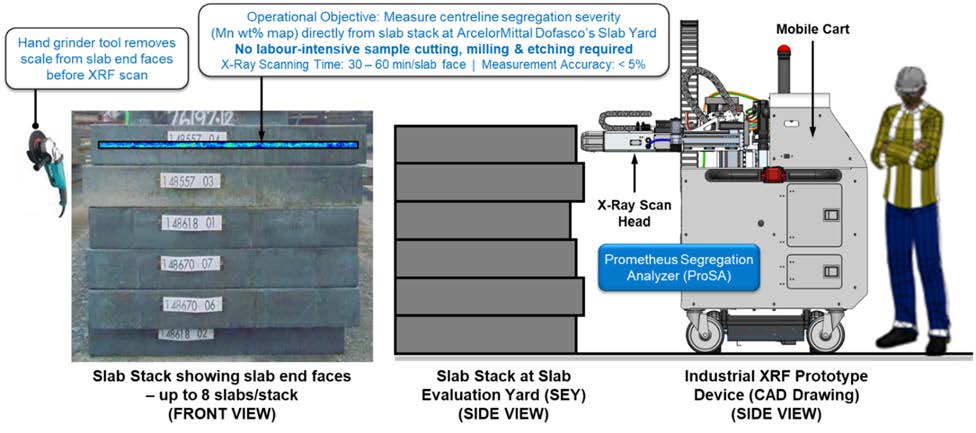

ProSA enables true at-line, nondestructive analysis of slab end faces. Mounted on a mobile, rugged cart, the instrument scans slabs stacked in the yard, producing quantitative elemental maps (e.g., Mn, Cr) with an error of less than 5% in under an hour per face. The maps are digital, objective, and suitable for statistical process control, replacing subjective visual evaluations.

Figure 2:Comparison between the traditional etched macrograph (left) and the Mn wt% map (right) from the same AHSS slab sample. The MXRF map reproduces the segregation pattern without destructive preparation.

But what’s the most significant breakthrough? ProSA’s data feeds directly into the process control loop, enabling steelmakers to make timely adjustments to continuous casting parameters and cooling profiles.

Figure 3: Schematic illustration of the ProSA system scanning stacked slabs in the evaluation yard, removing the need for destructive sample preparation.

Closing the Loop: How ProSA Data Improves Production

Traditionally, only a few slabs per day were destructively evaluated for internal quality. By the time defects were identified, hundreds of tons may have already been processed. With ProSA, dozens of slabs can be scanned daily, and the data is immediately available to metallurgists and casting engineers.

Here’s how it helps:

Caster Parameter Adjustment: ProSA’s Mn wt% maps reveal the severity of segregation across the slab’s width. If certain caster mold zones show persistent enrichment, flow control, and secondary cooling parameters can be adjusted mid-shift to minimize defects in subsequent slabs.

Slab Sorting and Downgrade Avoidance: Slabs with higher-than-normal segregation can be flagged for alternate downstream processing or diverted from critical applications, preventing scrap and customer complaints.

Caster Maintenance Scheduling: Longitudinal trends in segregation maps can help identify mold wear or nozzle blockage before a defect appears in the final product.

Statistical Process Control: Quantitative data (mean wt%, standard deviation, RSD, segregation width) from ProSA maps enables timely statistical tracking across shifts and casters, supporting continuous improvement efforts.

This feedback loop transforms ProSA from a diagnostic tool into a preventive control mechanism, essential for modern quality systems such as Six Sigma or IATF 16949.

Why It Matters: Downstream Benefits

The impact of stricter control over centerline segregation is significant. For end users, this results in stronger, more reliable, and defect-free steel in their products. Several key industries stand to benefit directly:

1. Automotive safety components

Martensitic banding from segregation weakens critical areas in crash zones. ProSA data helps reduce this variability, making components like door beams and roof rails more consistent and safer.

2. High-rise and bridge construction

HSLA steels in infrastructure must endure stress and corrosion over decades. The uniformity ensured by ProSA maps leads to fewer weld failures and more predictable load-bearing performance.

3. Consumer and industrial appliances

Steel for appliance exteriors or server racks must adhere to stringent dimensional and surface property tolerances. Eliminating internal inconsistencies alleviates formability issues and improves throughput in forming lines.

Designed for Industry, Proven in the Field

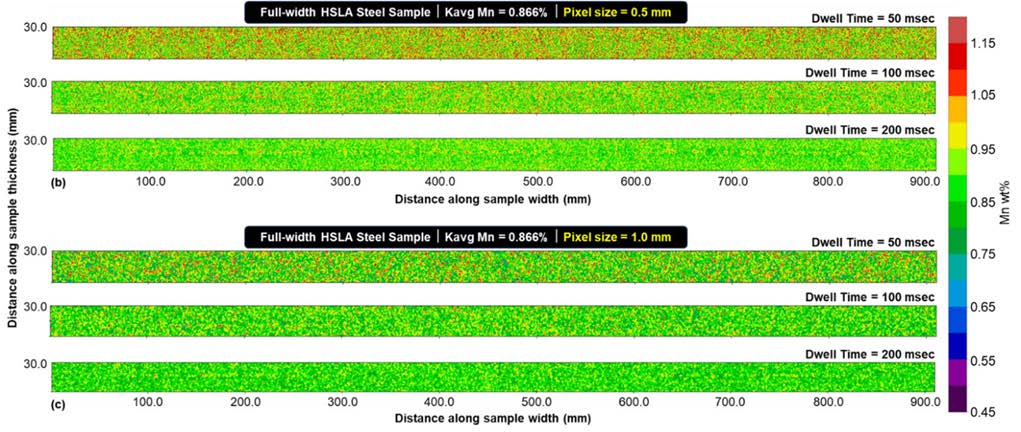

With a safety-certified design, integrated proximity sensors, real-time scan controls, and no need for dosimetry, ProSA is designed for industrial environments. It was successfully deployed at ArcelorMittal Dofasco’s slab evaluation yard and has since demonstrated full-width Mn wt% mapping with an error of less than 4%.

Figure 4. Mn wt% maps generated by ProSA from a full-width HSLA slab sample. Results show excellent agreement with expected segregation profiles with <4% measurement error.

As a result, ProSA has not only reduced analysis time but is also actively shaping how casters are operated, maintained, and controlled.

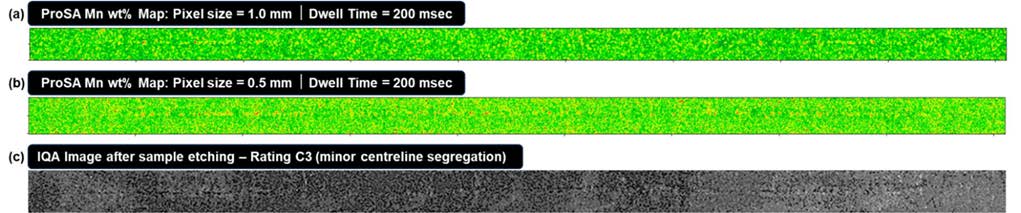

Figure 5. Visual comparison of ProSA-generated Mn wt% maps and a traditional etched macrograph from a full-width slab. Both reveal similar segregation severity.

The Future of Steelmaking Starts at the Slab

With ProSA, IXRF Systems has redefined what’s possible in steel quality assurance. By delivering timely, quantitative insights directly from the production floor, ProSA empowers steelmakers to move from reactive correction to proactive control. It eliminates the guesswork, cuts the lag between detection and response, and ensures every slab contributes to stronger, more uniform, and more reliable end products.

Whether you’re casting for safety-critical automotive parts, high-performance structural steel, or precision-formed appliances, ProSA gives you the power to catch defects before they become costly problems—and to raise your production standards like never before.

Don’t wait to catch problems downstream—solve them at the source.

Let’s change the future of steelmaking—one slab at a time.

References

- Sengupta, J., Rustagi, T., Poort, L., Nicholls, M., Ma, A., Swehosky, F., Burger, D., Ruchte, B., and Williams, B.

“Introducing an Industrial X-Ray Fluorescence Prototype Device for Measuring Centerline Segregation Severity Directly from Slab Stacks at ArcelorMittal Dofasco.” AISTech 2025 Conference Proceedings, 2025. - Sengupta, J. et al. “Qualitative and Quantitative Techniques for Evaluating Mn Segregation in Advanced High Strength Steels at ArcelorMittal Dofasco’s No. 1 Continuous Caster.” AISTech Conference Proceedings, 2011.

- Alibeigi, S., Sengupta, J., and Biro, E. “Quantification of Martensitic Banded Microstructure in Dual Phase Steels and its Application at ArcelorMittal Dofasco’s No.1 Continuous Caster.” METEC & ESTAD, 2015.

- Laughlin, J. et al. “HD Scan – Ultrasonic Technology for Quantitative Evaluation of the Internal Quality of As-Cast Steel Products.” AISTech Conference Proceedings, 2016.

- Abraham, S. et al. “Development of an Image Analysis Technique for Quantitative Evaluation of Centerline Segregation in As-cast Products.” AISTech Conference Proceedings, 2016.

- Sengupta, J. and Leung, J. “Bridging the Gap: MXRF Technique Rapidly Maps Centerline Segregation.” AISTech Conference Proceedings, 2016.

- Sengupta, J., Leung, J., and Noorafkan, A. “Calibration and Validation of X-Ray Fluorescence Technique for Mapping Centerline Segregation on Steel Slabs.” AISTech Conference Proceedings, 2017.

- Sengupta, J. and Noorafkan, A. “Quantifying Slab Centerline Segregation: MXRF Eliminates Sample Preparation and Etching Procedures.” AISTech Conference Proceedings, 2018.