⚡ TL;DR Summary

The Atlas Apex MicroXRF gives aerospace organizations high-resolution, non-destructive elemental analysis that significantly improves materials confidence. It enables engineers to verify complex alloys, coatings, and additive-manufactured parts with micro-scale precision, accelerating R&D, strengthening supplier verification, and enhancing QA/QC reliability. By delivering faster, more accurate chemical insights, the Atlas Apex reduces risk, shortens development cycles, and provides a measurable competitive advantage for aerospace manufacturers and research teams.

Introduction: Why Today’s Aerospace Materials Require Better Verification

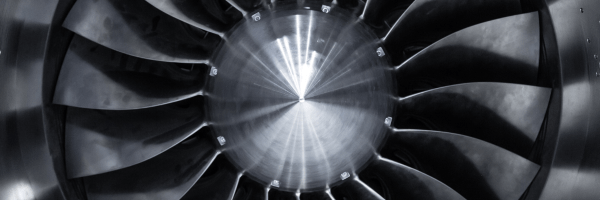

Aerospace materials analysis is essential for the advancement of technology in both aircraft and spacecraft. Trust in these materials is the cornerstone of innovation in the aerospace sector. Every component—from turbine blades and coating systems to composite parts and additively manufactured structures—must endure extreme mechanical and thermal conditions. As next-generation materials become increasingly sophisticated and complex, the need for rapid, precise, and non-destructive chemical verification has never been more critical.

Traditional analytical tools are increasingly insufficient for aerospace organizations under pressure to validate chemistry, confirm microstructural uniformity, and accelerate quality assurance. The industry needs instrumentation that brings clarity to complexity.

The Atlas Apex MicroXRF from IXRF Systems delivers exactly that: high-resolution, non-destructive elemental mapping engineered to elevate aerospace materials confidence.

Aerospace Materials Are Becoming More Complex—and More Critical

Three macro forces are reshaping aerospace materials strategy:

- Advanced Materials Introduce Micro-Scale Challenges: Titanium aluminides, nickel-based superalloys, ceramic-matrix composites, and thermal barrier coatings have microstructural gradients that directly affect fatigue life, oxidation resistance, and thermal stability.

- Global Supply Chains Increase Verification Demands: As vendors diversify, aerospace organizations must authenticate alloy chemistry and coating composition faster and more reliably.

- Sustainability and Lightweighting Present Analytical Unknowns: Novel alloys, recycled inputs, and new chemistries require more rigorous QA/QC to ensure long-term operational reliability.

Accuracy is no longer enough—organizations need non-destructive, micro-scale certainty.

The Atlas Apex MicroXRF: Precision Without Compromise

The Atlas Apex MicroXRF was engineered to exceed the analytical demands of today’s aerospace sector. It introduces a new level of confidence in materials by combining spatial precision, broad elemental coverage, and unmatched quantification performance.

- Micro-Scale Resolution for High-Stake Engineering Decisions

- Spot sizes down to 5–10 µm illuminate critical interfaces and microstructural gradients.

- Full-field elemental mapping reveals phase segregation, coating uniformity, diffusion zones, inclusions, and anomalies that traditional tools miss.

- Completely non-destructive—even for finished components and complex shapes.

- Quantitative Integrity That Accelerates Certification

- High-flux X-ray sources deliver exceptional count rates and low detection limits.

- Multi-detector configurations provide improved precision and stability.

- Algorithmic correction enhances quantification accuracy for nickel, titanium, aluminum, coatings, and AM structures.

The result is data aerospace engineers can trust for certification, compliance, and cross-vendor validation.

- Operational Efficiency Across R&D and QA/QC

- Rapid elemental mapping reduces bottlenecks in metallurgy, coating development, and AM qualification.

- Automated workflows streamline high-volume evaluations.

- Zero destructive preparation lowers costs and cuts rework risk for high-value components.

With the Atlas Apex, chemical imaging becomes a high-throughput capability—not a laboratory constraint.

Strategic Impacts for Aerospace Organizations

Deploying the Atlas Apex MicroXRF strengthens competitiveness across the materials lifecycle:

Accelerated R&D and Innovation – Engineers detect variations earlier—reducing iteration cycles in alloy development, coating design, and AM parameter tuning.

Enhanced Supplier Verification – Incoming materials can be authenticated in minutes, improving supply-chain resilience and reducing risk of non-conforming stock.

Higher Yield and Fewer Failures – Localized inconsistencies, coating defects, and contamination signals are detected before they translate into production failures or field risks.

Regulatory and Certification Confidence – Quantitative, archival-grade data supports stringent aerospace documentation and audit requirements.

For a sector defined by zero tolerance for error, the Atlas Apex provides a measurable strategic advantage.

Why Aerospace Leaders Are Turning to IXRF Systems

The aerospace industry is accelerating innovation faster than legacy analytical tools can support. IXRF Systems designed the Atlas Apex MicroXRF as a forward-looking solution—capable of supporting:

- Aerospace R&D and materials development

- Thermal barrier coating validation

- Additive manufacturing qualification

- Multi-vendor alloy authentication

- High-resolution failure analysis

- Production QA/QC and in-process verification

By elevating materials confidence, the Atlas Apex empowers aerospace engineers, scientists, and production managers to make better decisions faster and with less risk.

Build Aerospace Materials Confidence with the Atlas Apex MicroXRF

Strengthen your R&D, production, and supplier verification programs with the most advanced non-destructive micro-scale elemental analysis platform available.

Request a demonstration or speak with an IXRF Systems specialist today.