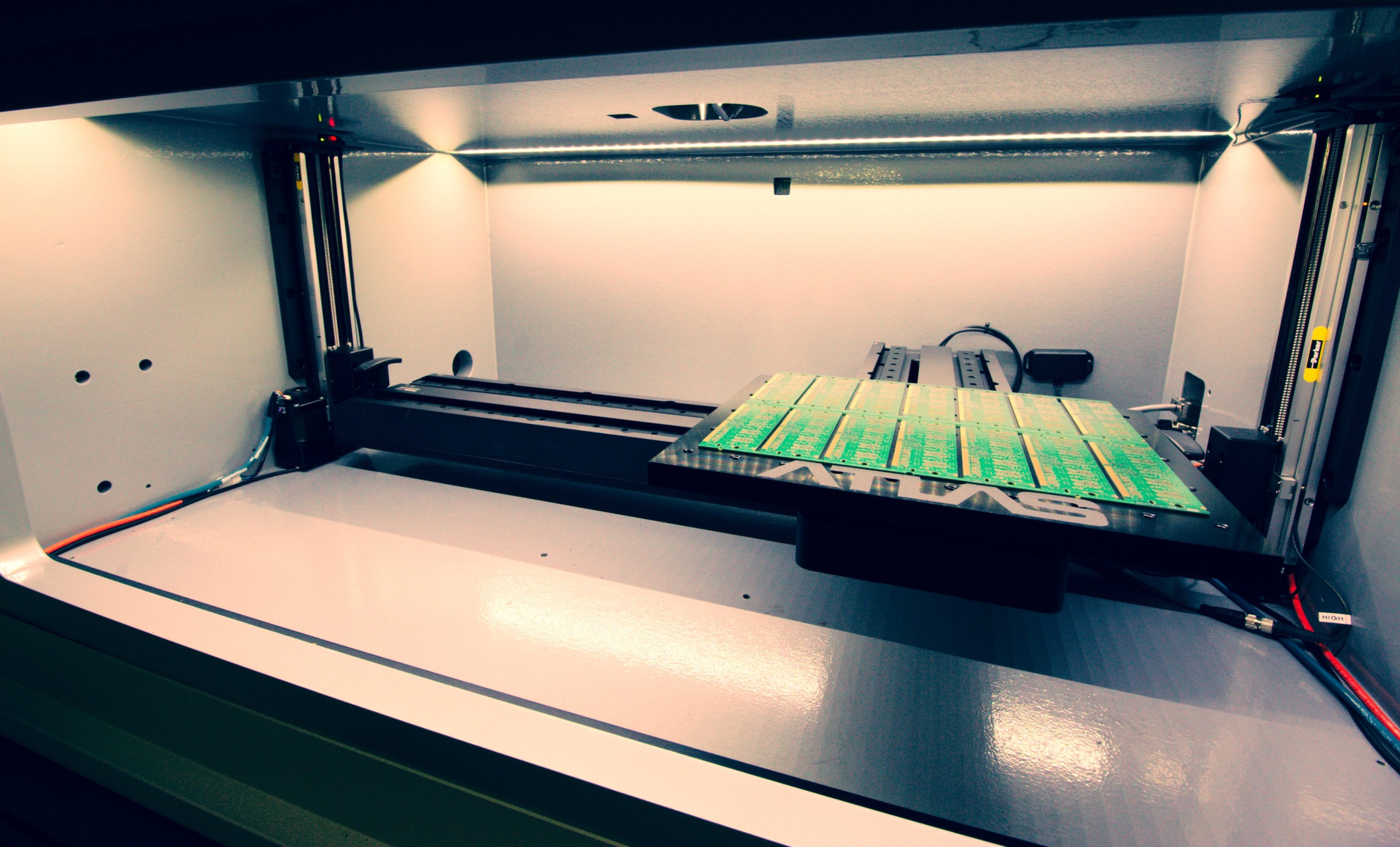

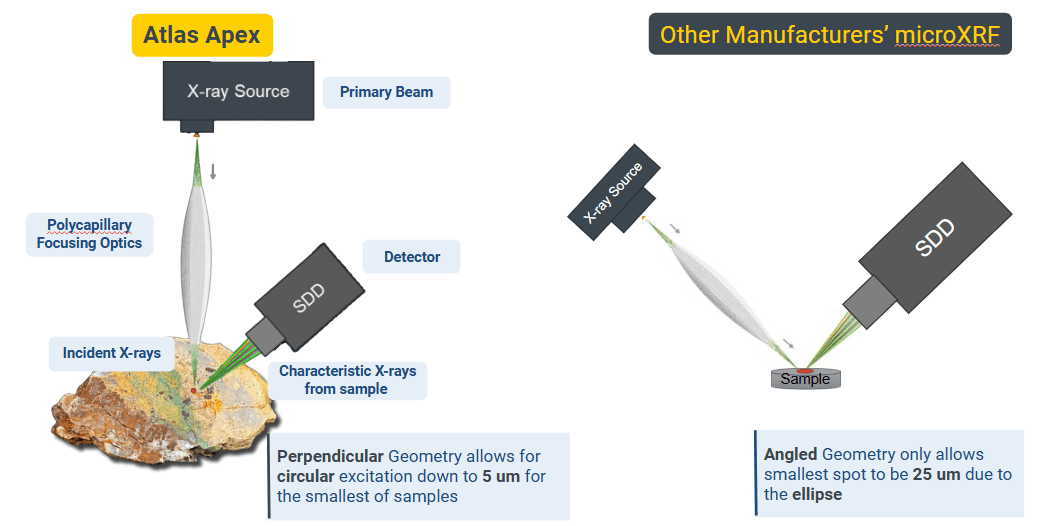

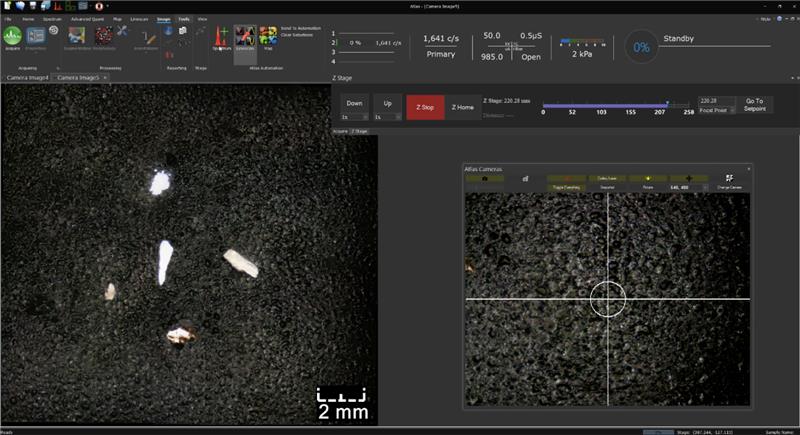

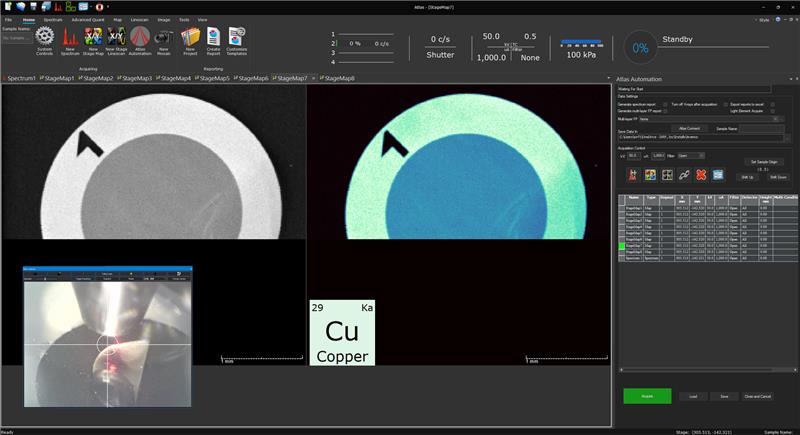

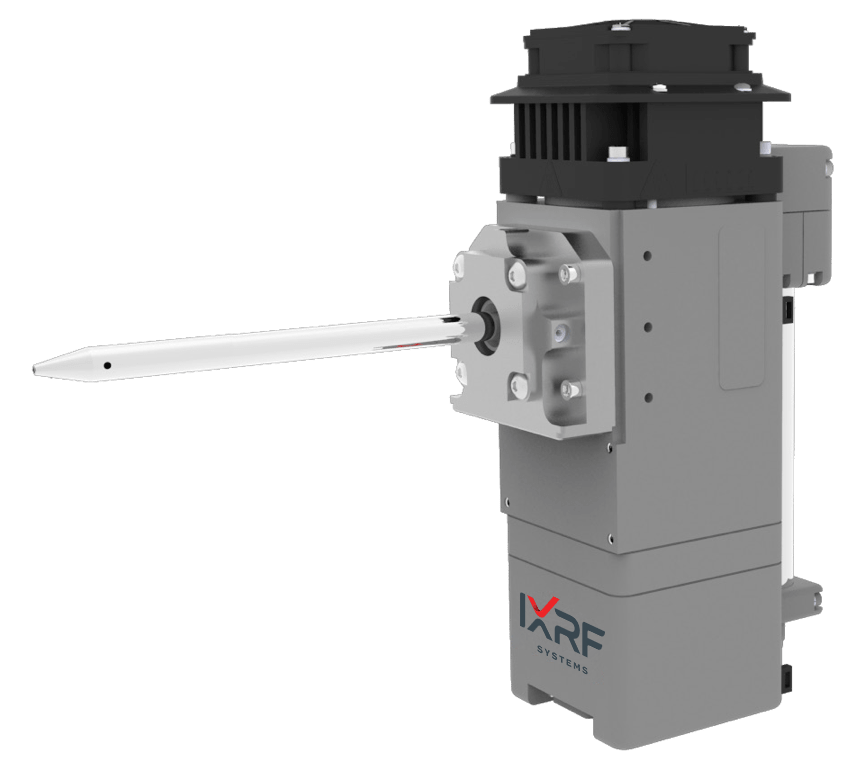

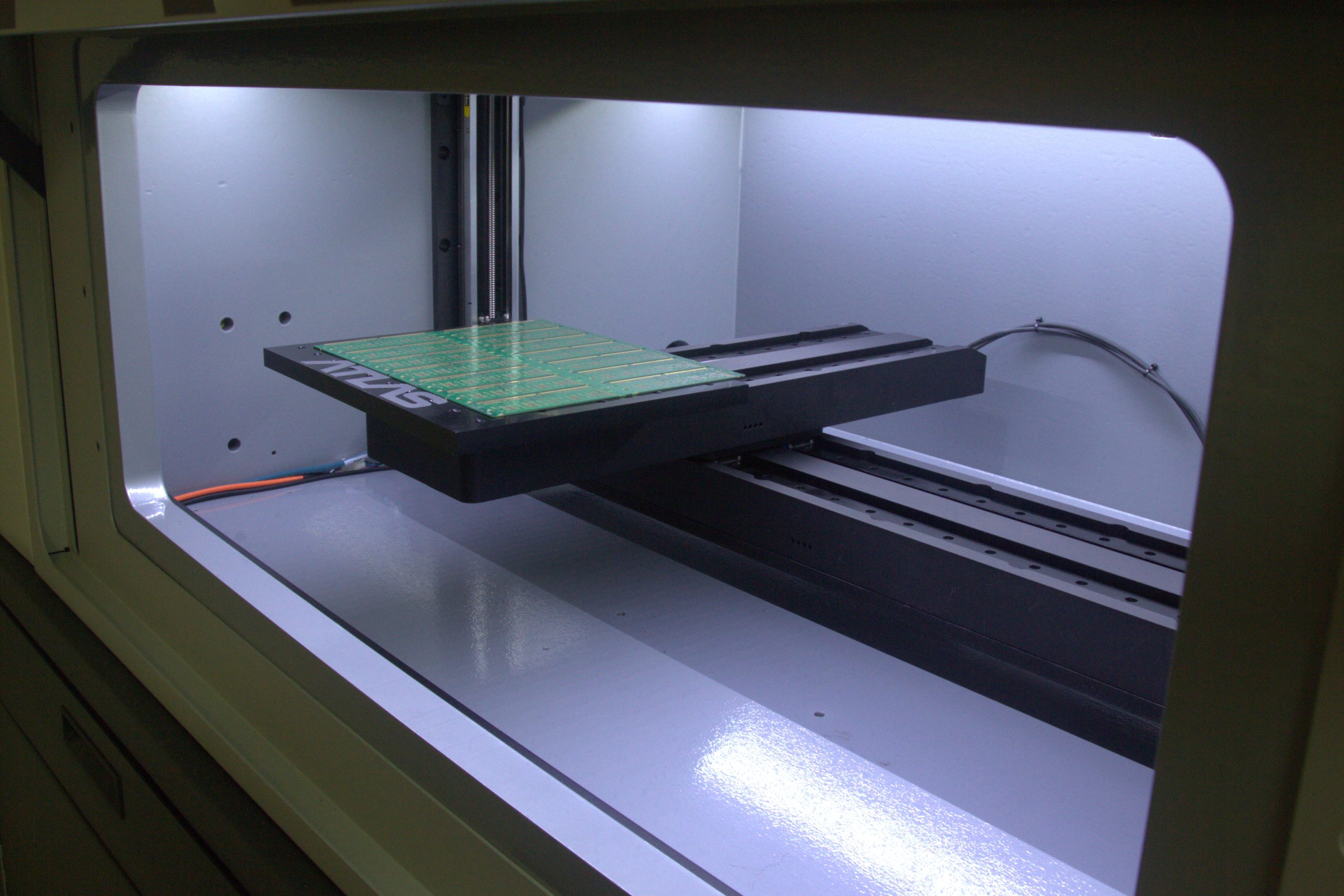

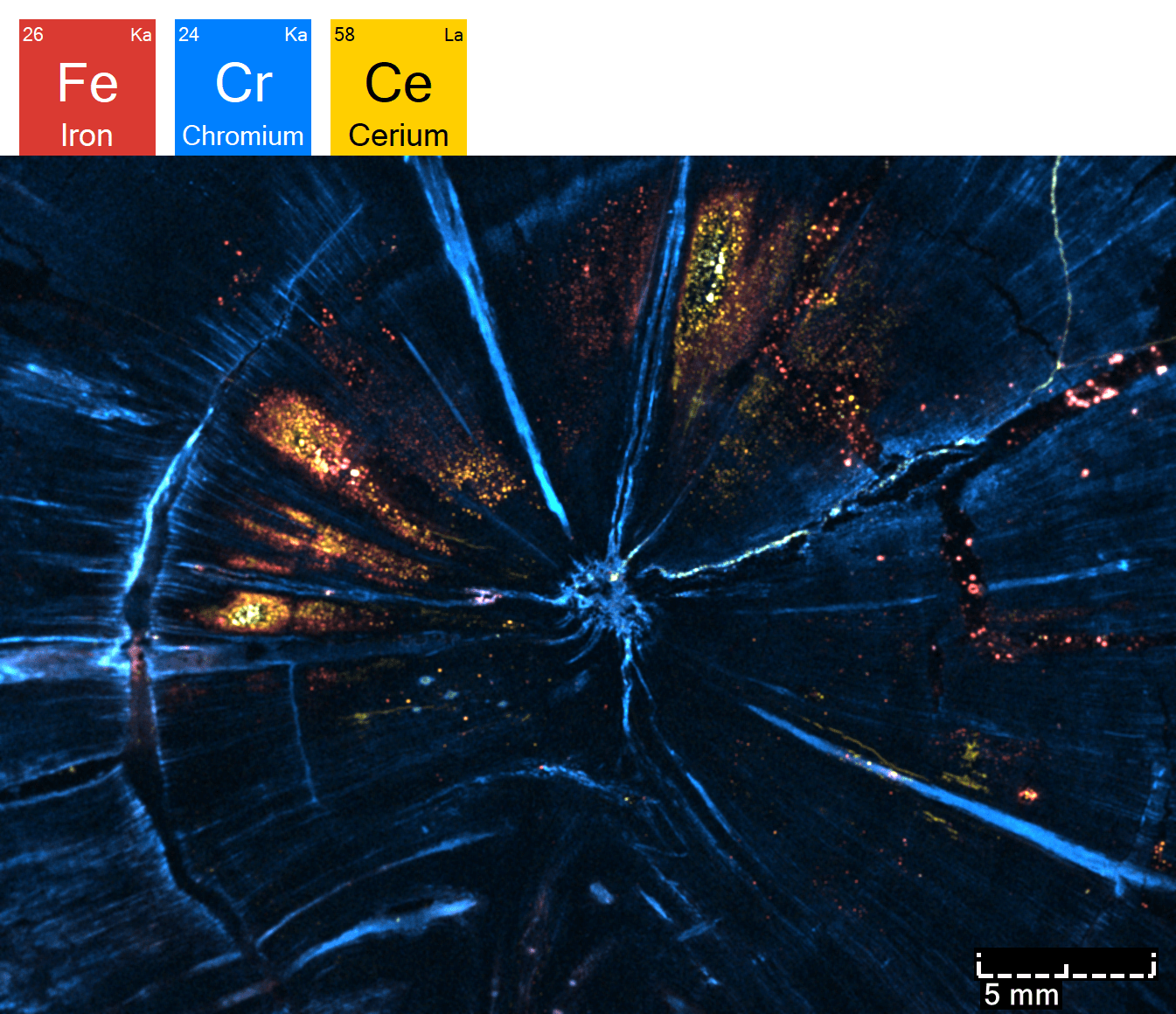

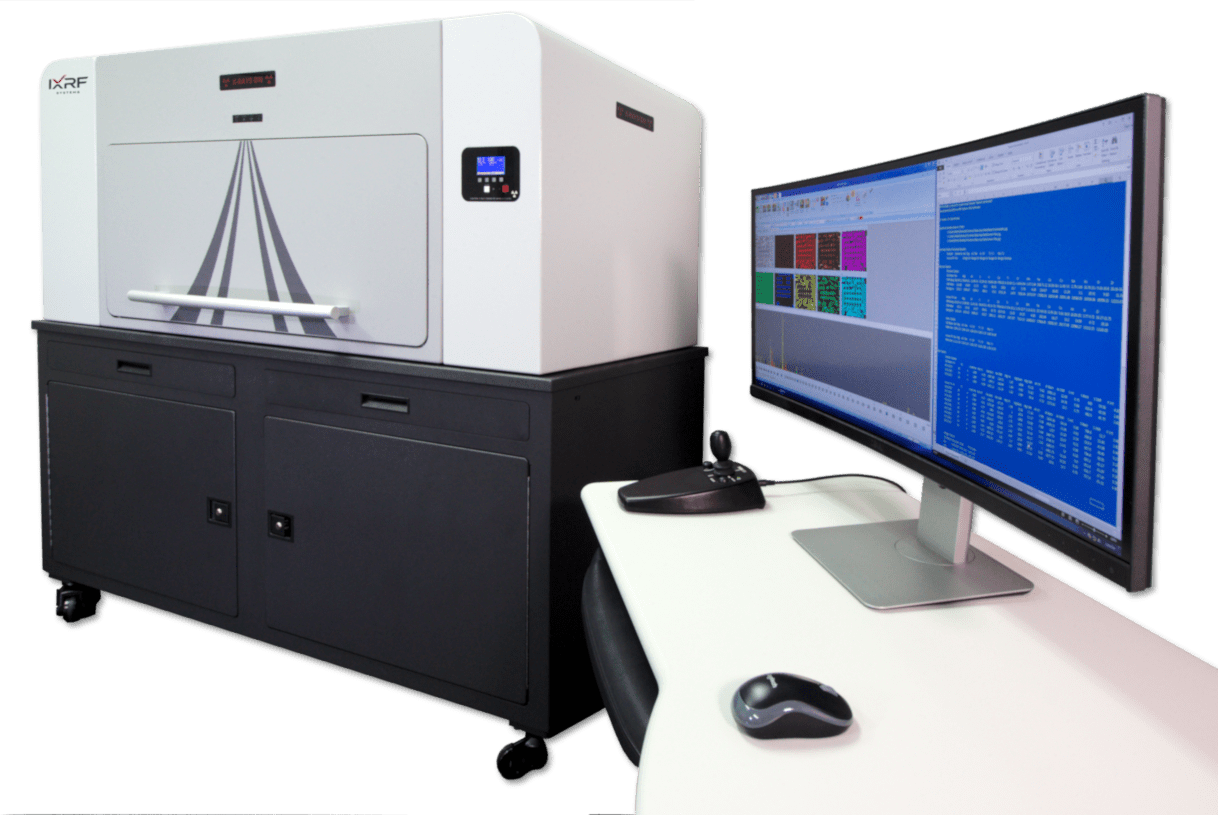

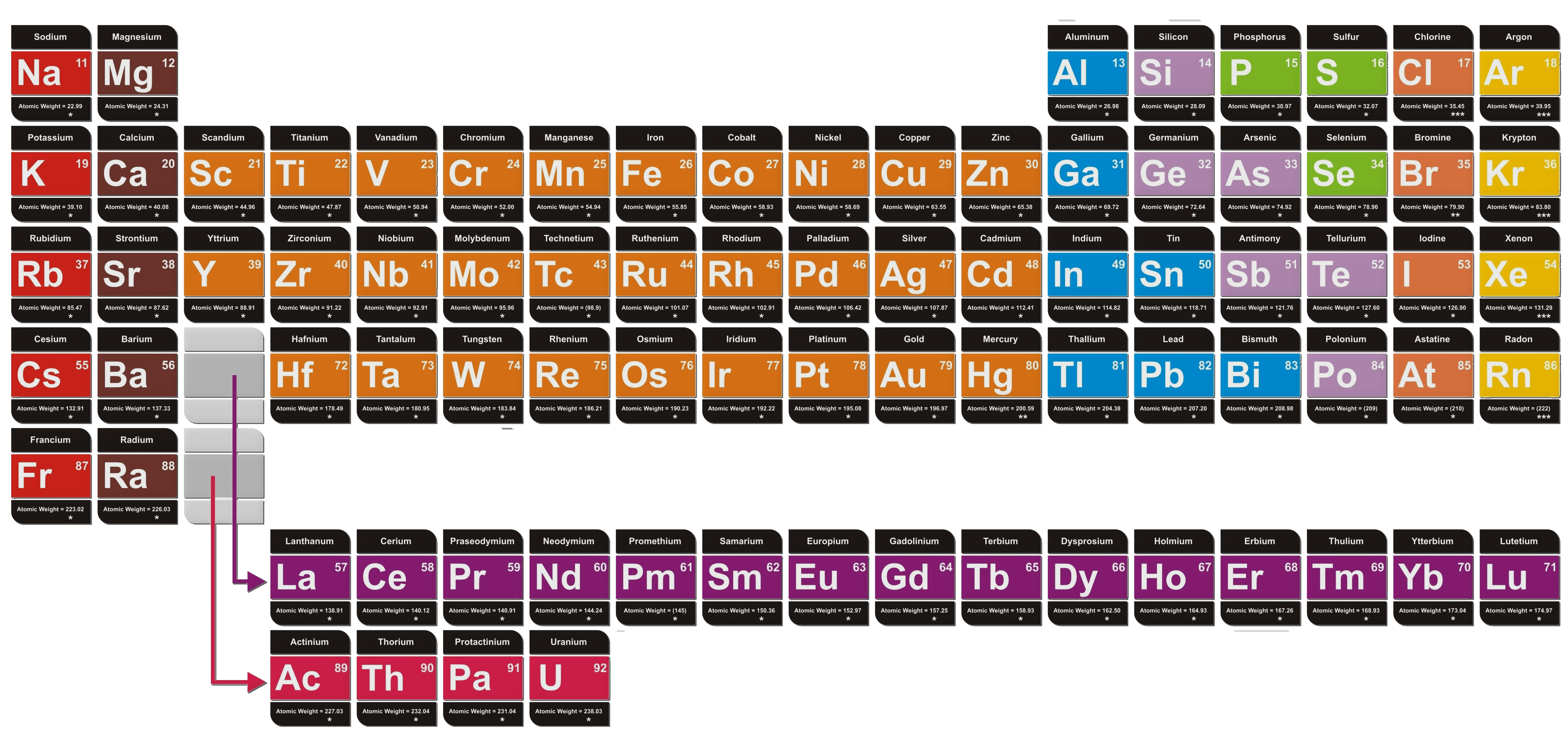

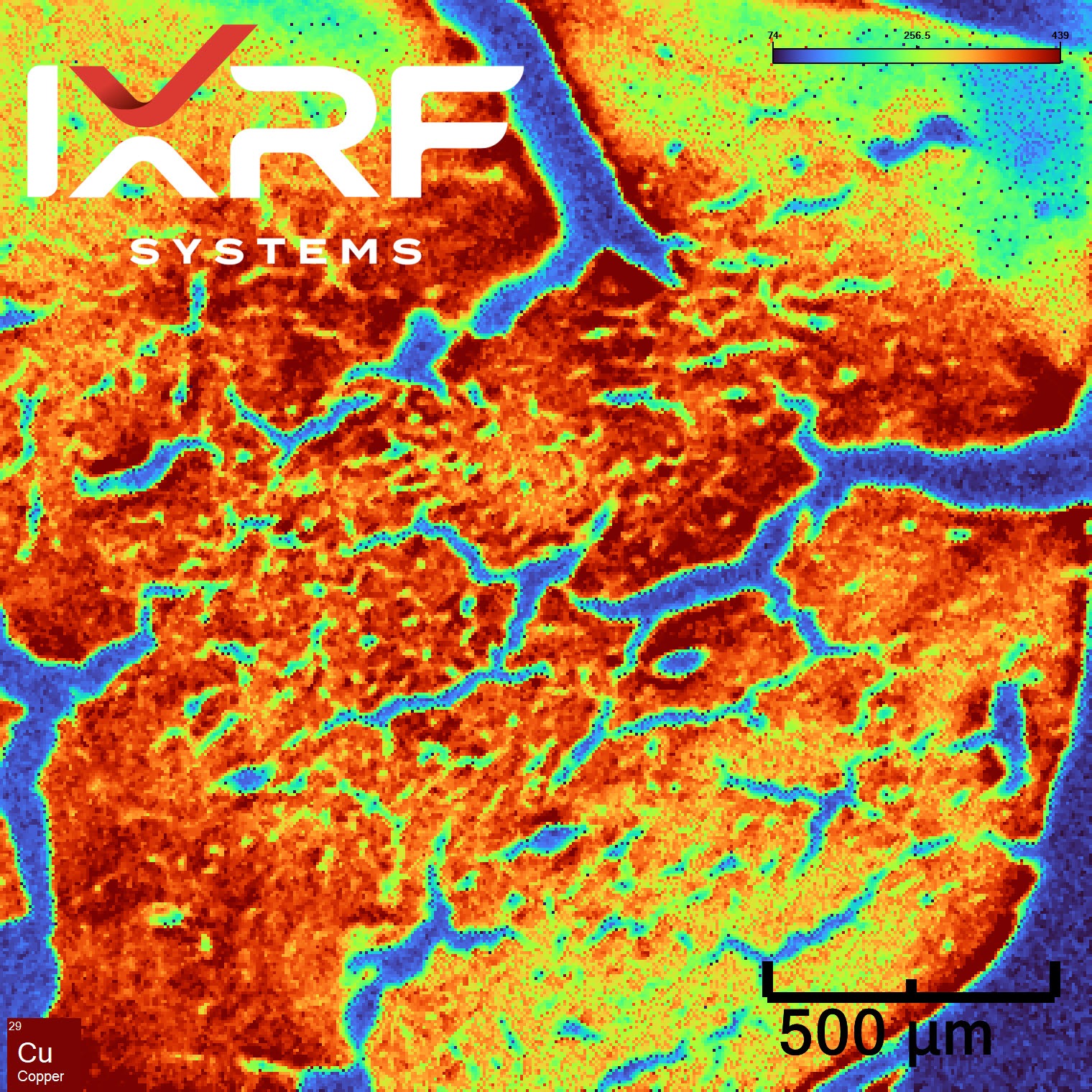

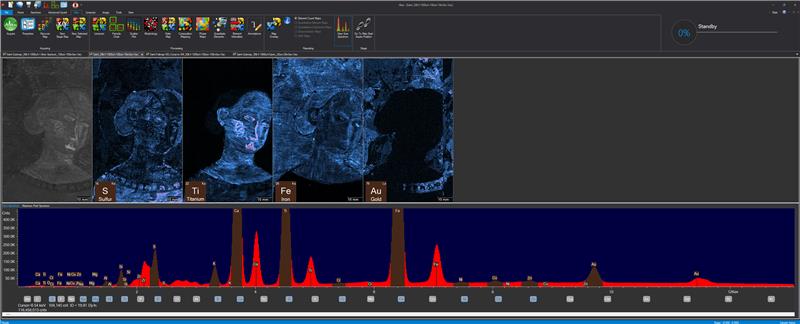

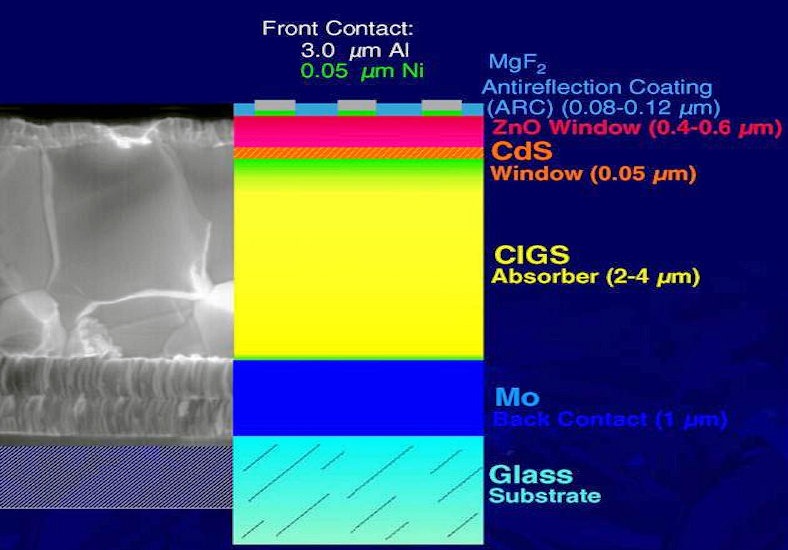

IXRF Systems’ ATLAS Apex X mainframe microXRF spectrometer is the latest general purpose, large chamber micro/small spot energy dispersive X-ray fluorescence (μXRF) spectrometer for the measurement and imaging/mapping of elements from carbon (C) through uranium (U). Designed to image and analyze a wide variety of sample types, ATLAS Apex X leads the industry in virtually every major specification category from the most powerful software and the largest detector active area, to our superior perpendicular geometry and tiny 5 μm diameter micro XRF spot.

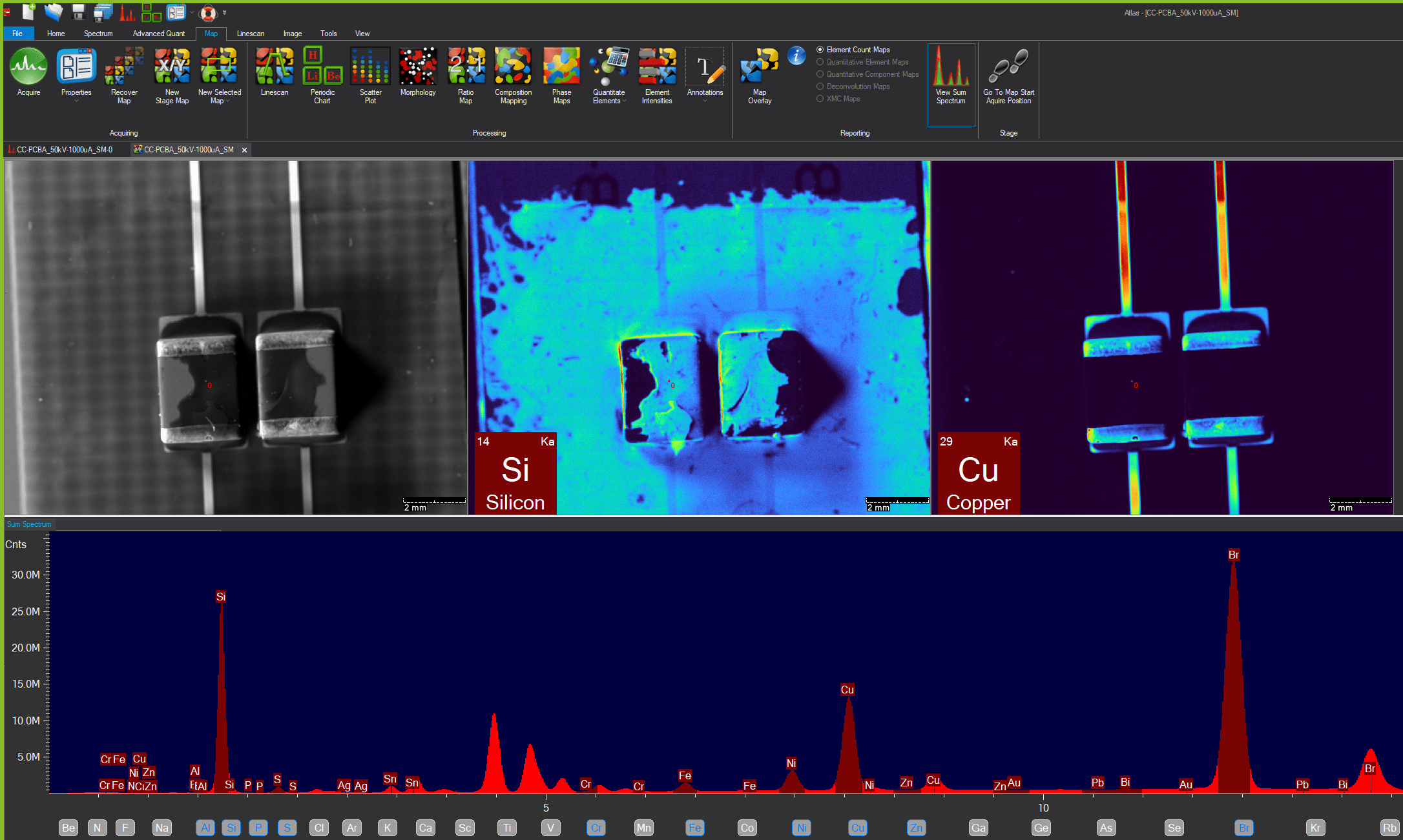

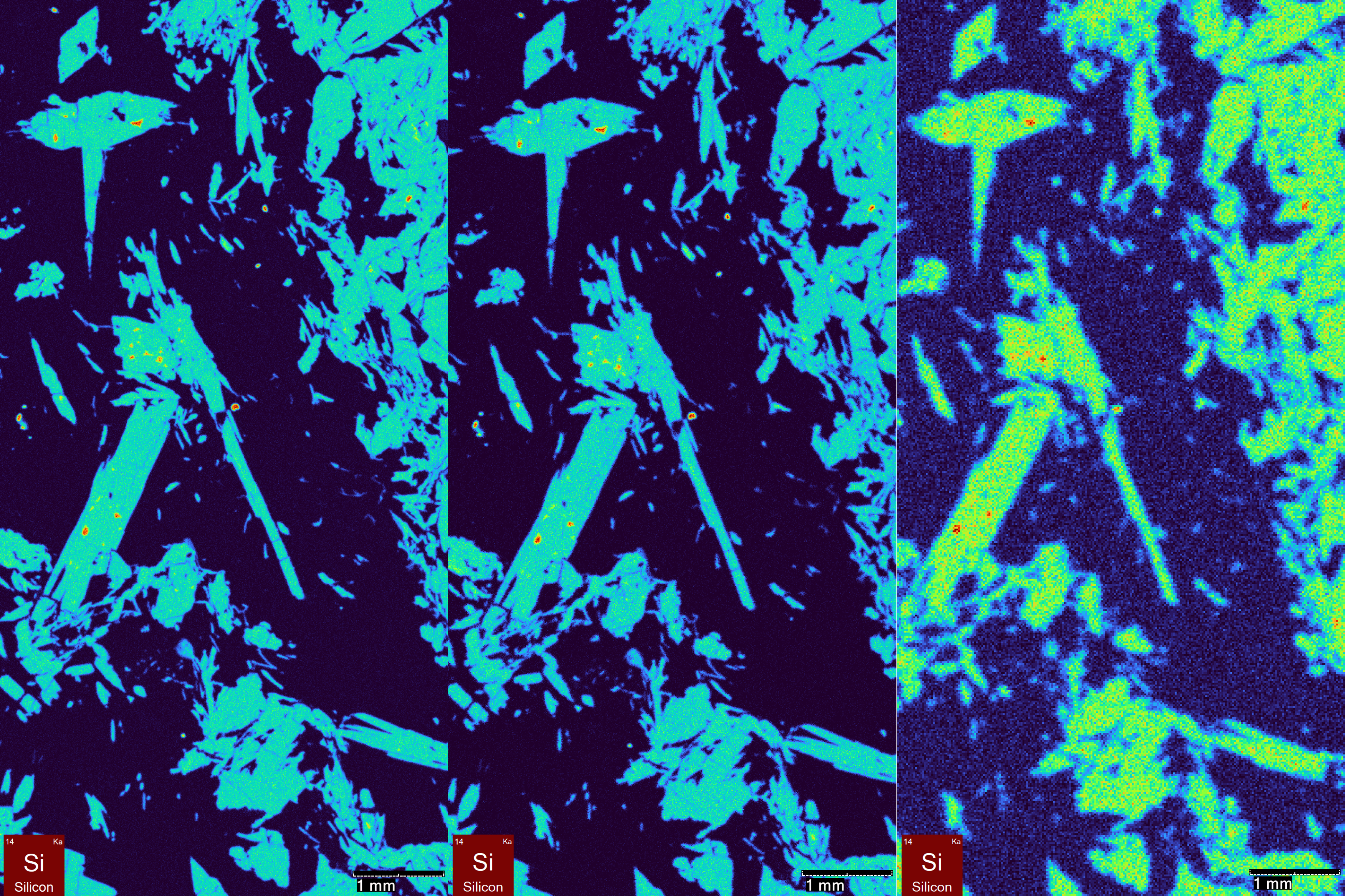

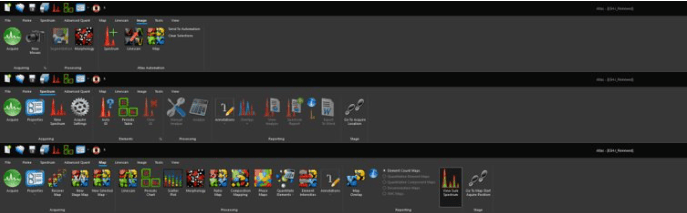

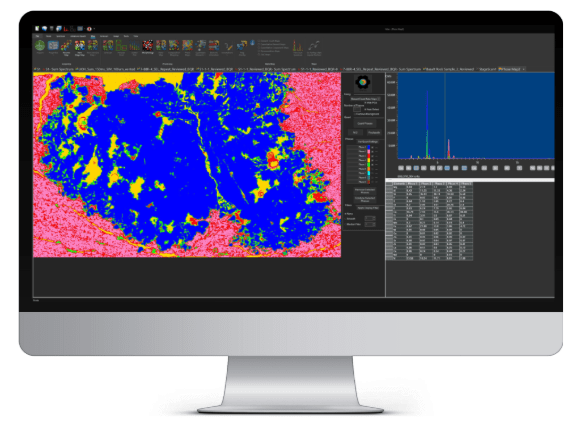

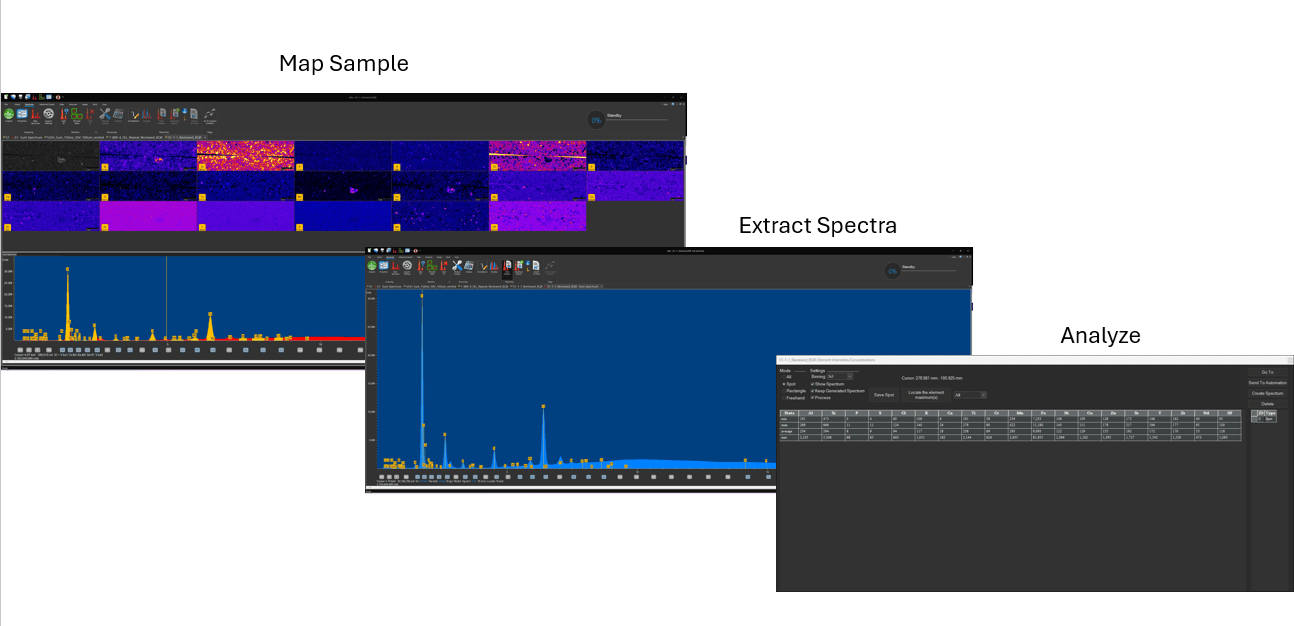

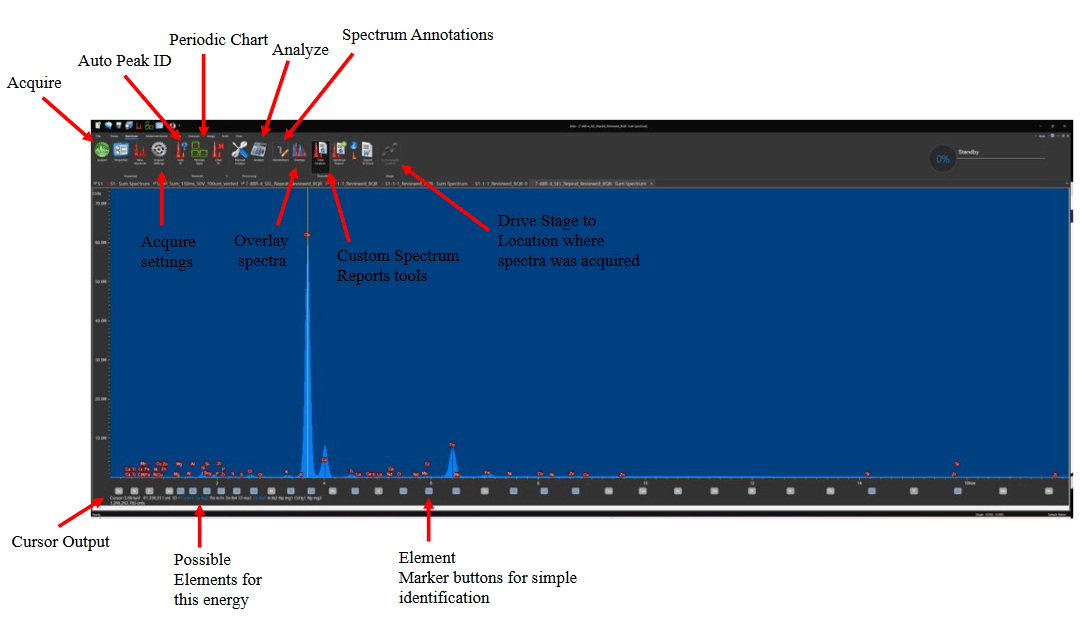

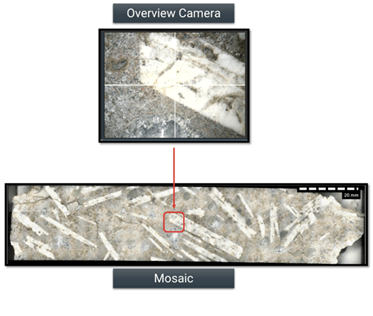

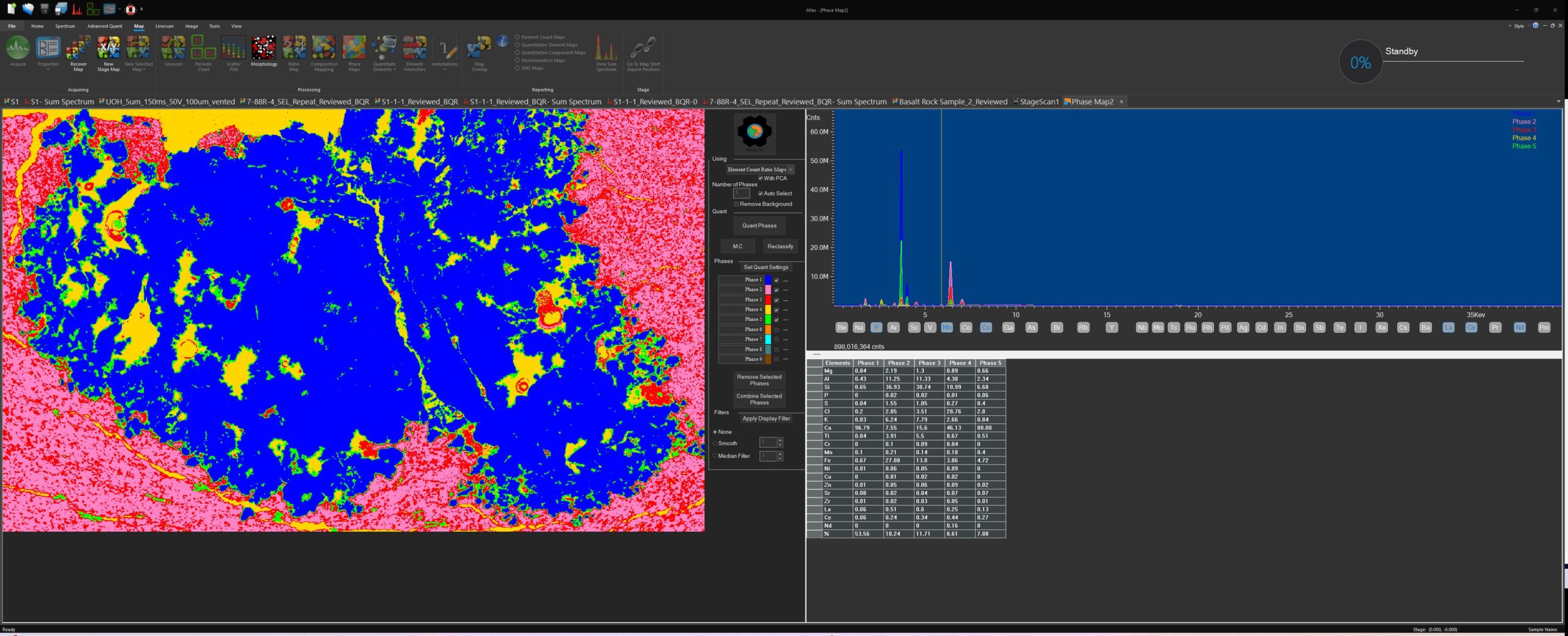

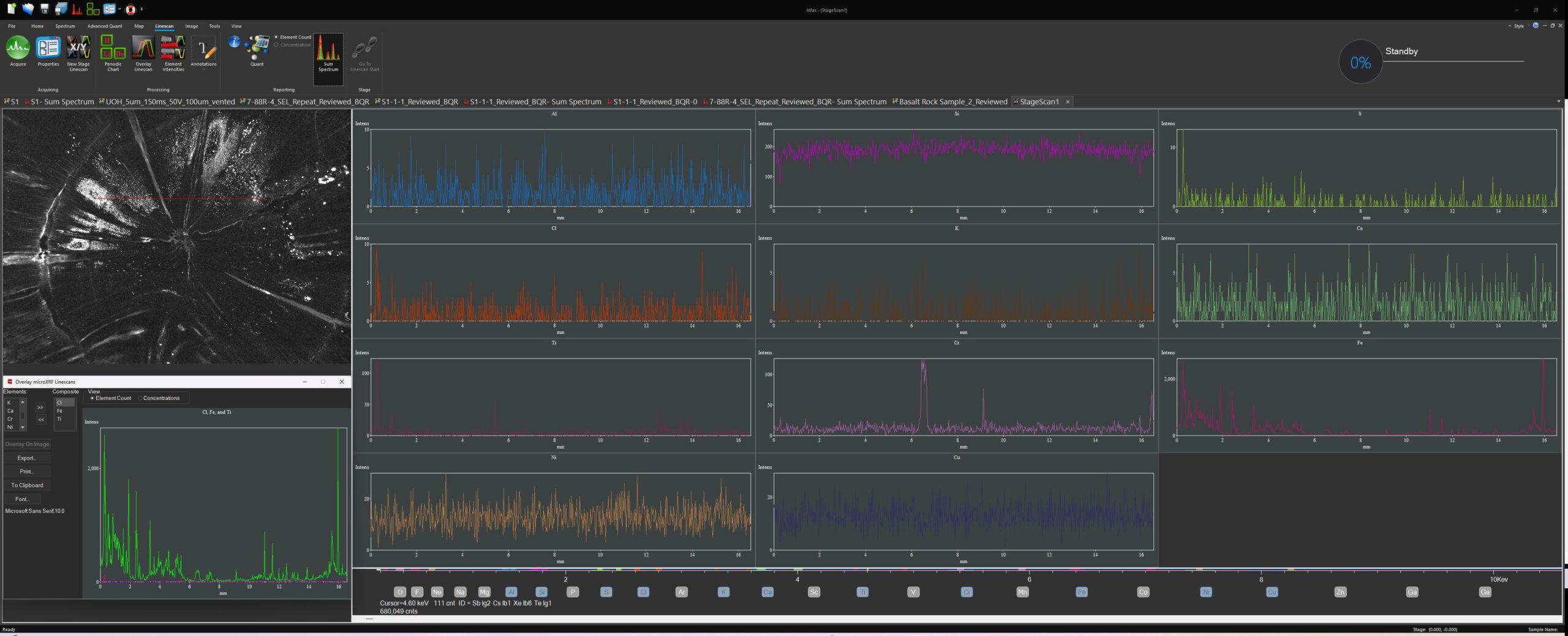

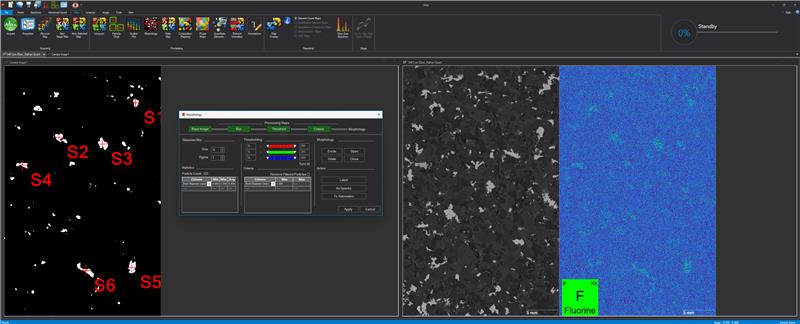

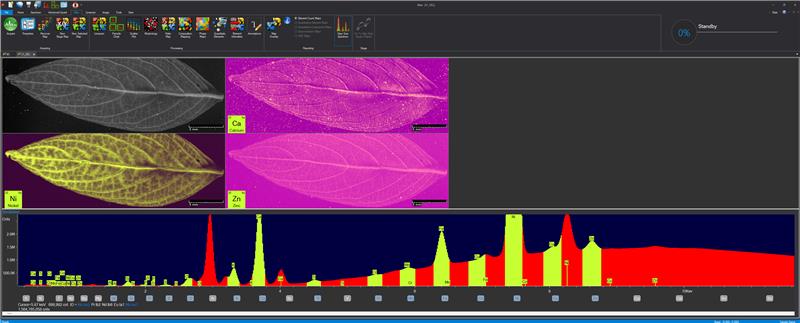

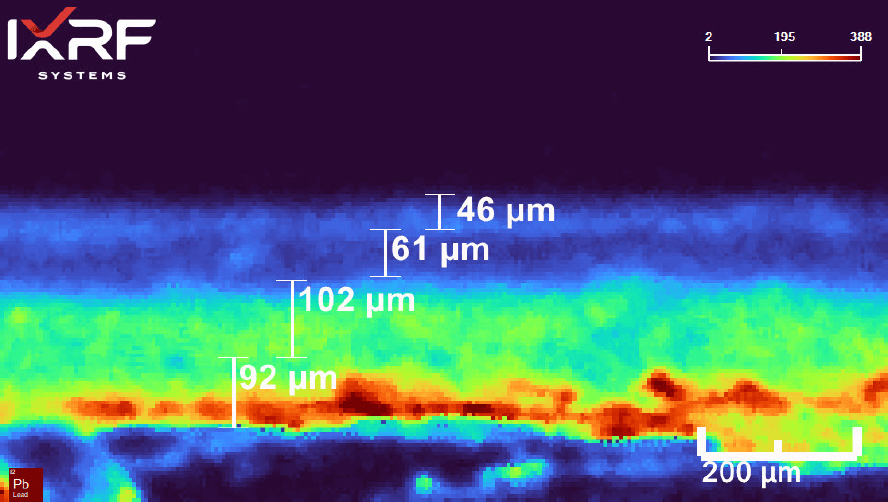

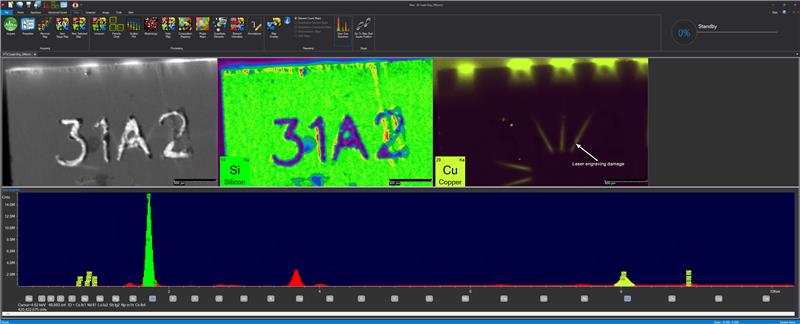

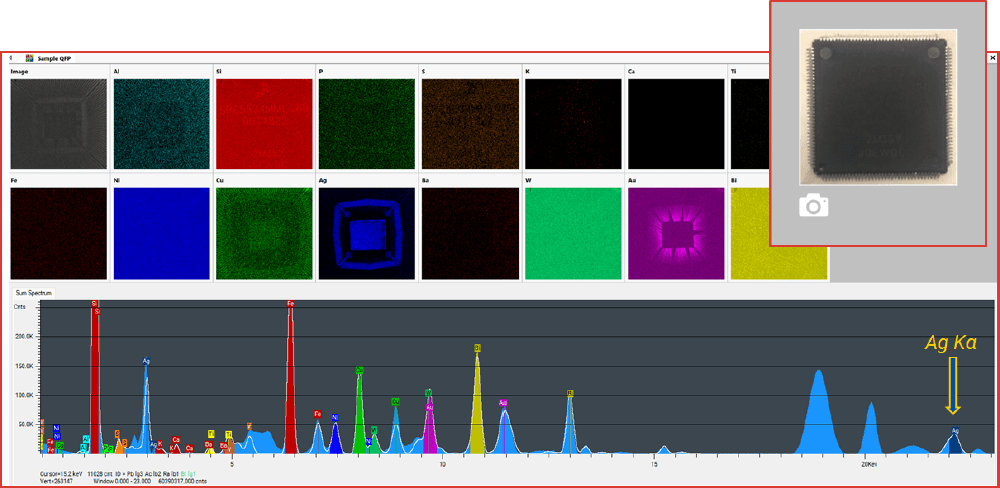

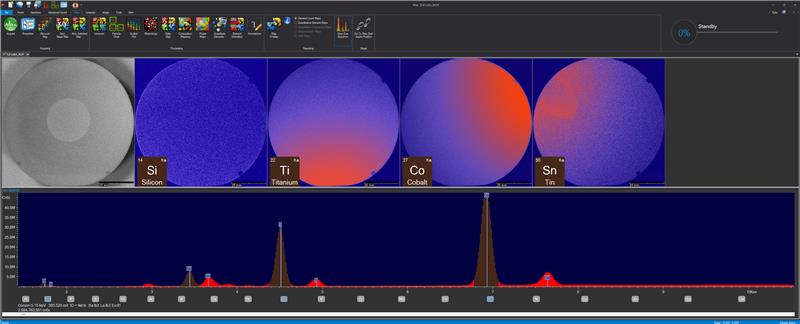

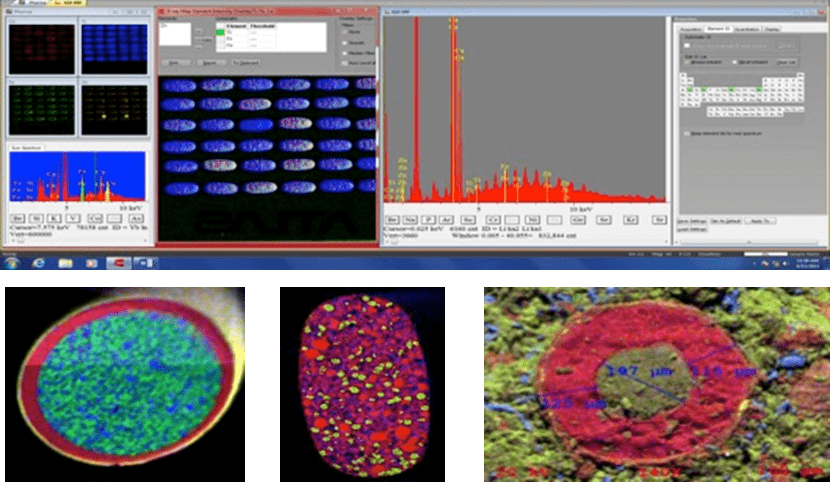

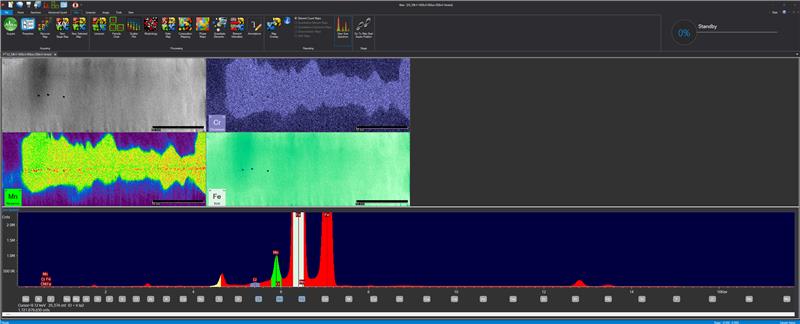

ATLAS Apex’ Iridium Ultra software platform, developed with SEM/EDX elemental mapping and analytical functionality, is unsurpassed in it’s ability to provide elemental and phase mapping, line scans, critical dimensions (CD) as well as qualitative and quantitative elemental analyses of solids, liquids, particles, powders and thin films. The functional, flexible, and feature-rich software suite guarantees unprecedented productivity. ATLAS Apex X is the microXRF (μEDXRF) elemental analyzer that leads the world with innovation.