⚡ TL;DR

High-spatial resolution micro-XRF is a powerful tool for identifying and unlocking critical minerals essential to modern technologies and energy transition efforts. The ATLAS micro-XRF enables precise, non-destructive elemental mapping—down to 5 µm—allowing researchers and industry professionals to locate trace concentrations of rare earth elements, transition metals, and other high-value materials within complex matrices. By visualizing mineral phases, inclusions, and micro-scale zoning patterns, micro-XRF reveals where critical minerals are concentrated and how they are distributed—helping guide extraction strategies, optimize beneficiation, and accelerate materials discovery across mining, geology, and resource recovery sectors.

Introduction

As the global economy accelerates towards decarbonization and clean energy technologies, access to critical materials is no longer just a supply chain issue—it has become a strategic imperative. In its 2023 Critical Materials Assessment, the U.S. Department of Energy (DOE) emphasized that the path to net-zero emissions by 2050 will be paved with materials such as lithium, cobalt, neodymium, gallium, and silicon carbide, all essential for powering electric vehicles (EVs), wind turbines, solar panels, and next-generation power electronics.

At IXRF Systems, we believe that materials characterization technologies must evolve to meet this demand. Our flagship system, the Atlas microXRF, delivers high spatial resolution microXRF elemental mapping and advanced elemental sensitivity—key enablers in identifying, sourcing, and validating these strategic materials.

The Materials Behind the Energy Transition

The DOE’s report identifies 23 materials as critical or near-critical through 2035, with particular concern for rare earth elements (REEs) like dysprosium and terbium, battery metals such as lithium and cobalt, and semiconductors like gallium and silicon carbide. These critical minerals are integral to the magnets in EV motors and wind turbines, the cathodes in lithium-ion batteries, and the wafers in power electronics.

However, the journey from resource to usable component is filled with bottlenecks. Supply chain constraints, geopolitical dependencies, and production inefficiencies challenge the secure delivery of these materials. To address these challenges, material scientists and engineers must be equipped with high-throughput, high-precision tools that can analyze samples quickly, accurately, and non-destructively.

MicroXRF: Precision Mapping for a Materials-Critical Future

Micro X-ray fluorescence (microXRF) spectroscopy is ideally suited to meet these challenges. With spot sizes down to 5 µm, IXRF’s Atlas system enables users to visualize and quantify the distribution of critical elements in ores, magnets, battery components, and recycled materials. Whether verifying the quality of gallium nitride wafers or identifying trace rare earth elements in complex mineral phases, the Atlas microXRF analyzer provides both the spatial resolution and elemental range (C to U) required for meaningful, high-resolution mineral mapping.

Unlike traditional analysis techniques such as digestion-based ICP-MS or bulk XRF, which require sample destruction, lengthy preparation, or only provide average composition values, microXRF offers non-destructive, spatially resolved elemental imaging. This capability enables scientists to identify micron-scale heterogeneities and zonation patterns that are often invisible to conventional methods, unlocking insights into mineral structure, formation, and economic viability.

For mineral exploration and mining, microXRF provides unparalleled advantages in speed, cost-effectiveness, and versatility. It bridges the gap between SEM-EDS and bulk elemental assays by enabling rapid, broad-area scanning with high elemental sensitivity, all without the need for vacuum systems or conductive coatings.

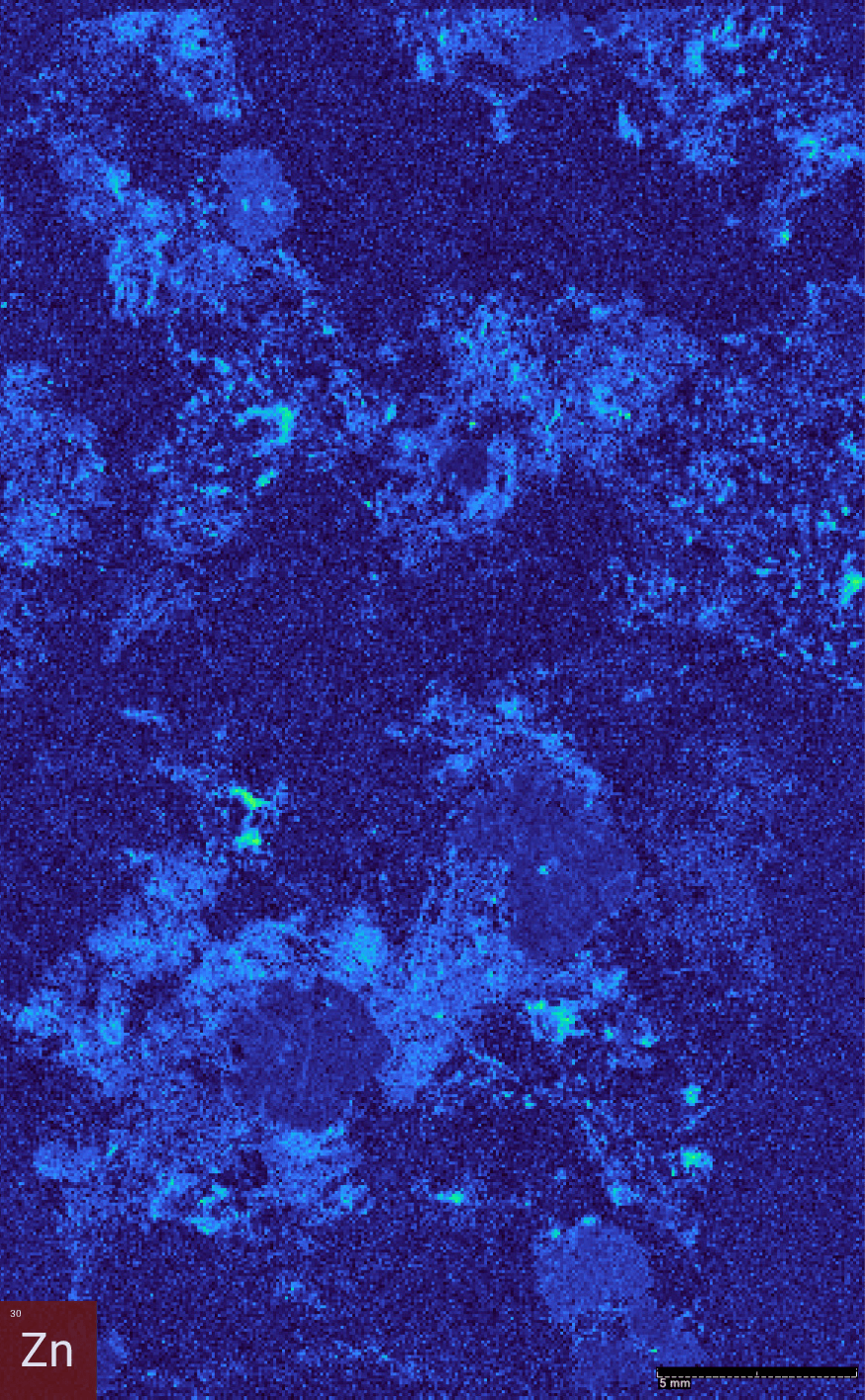

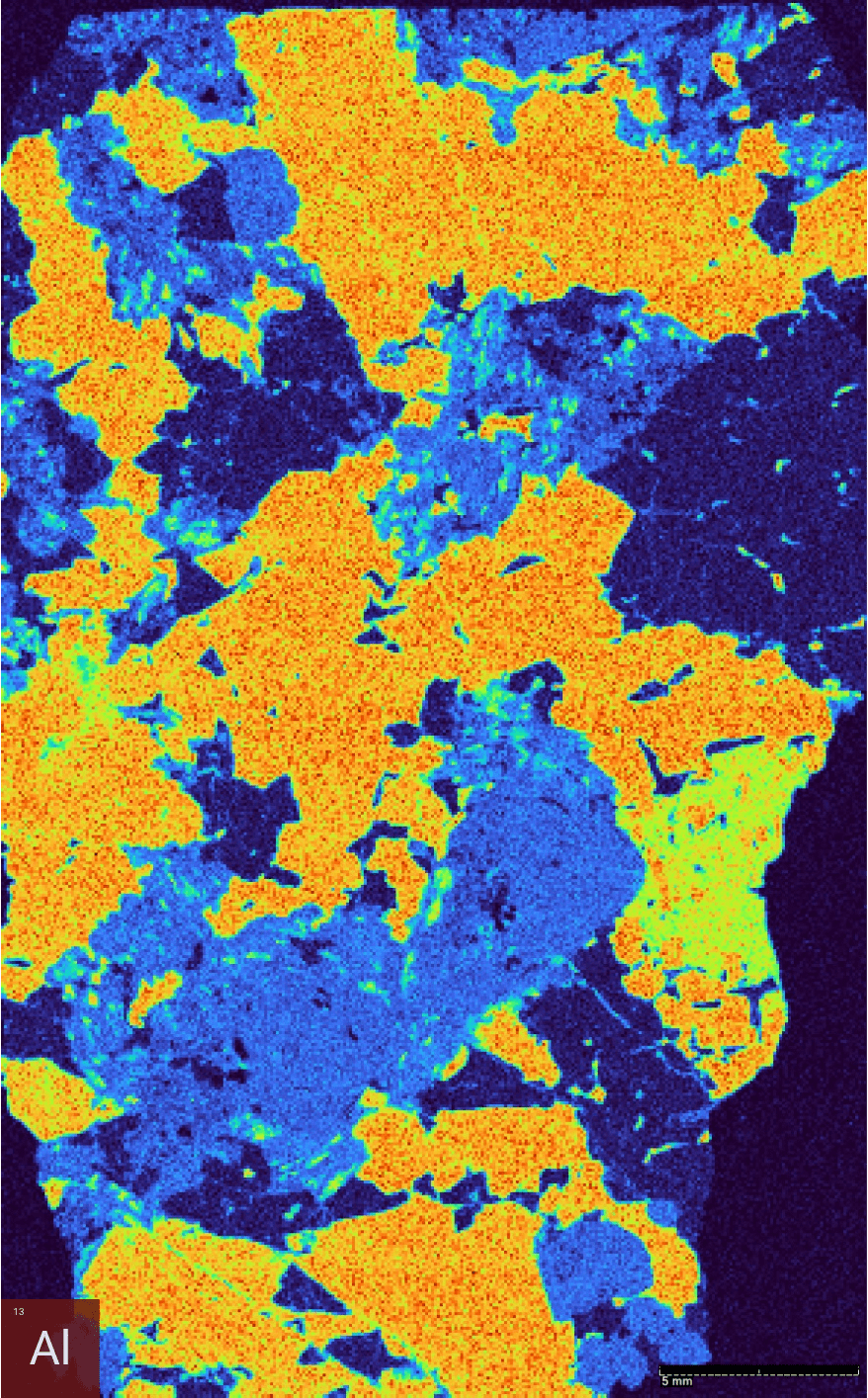

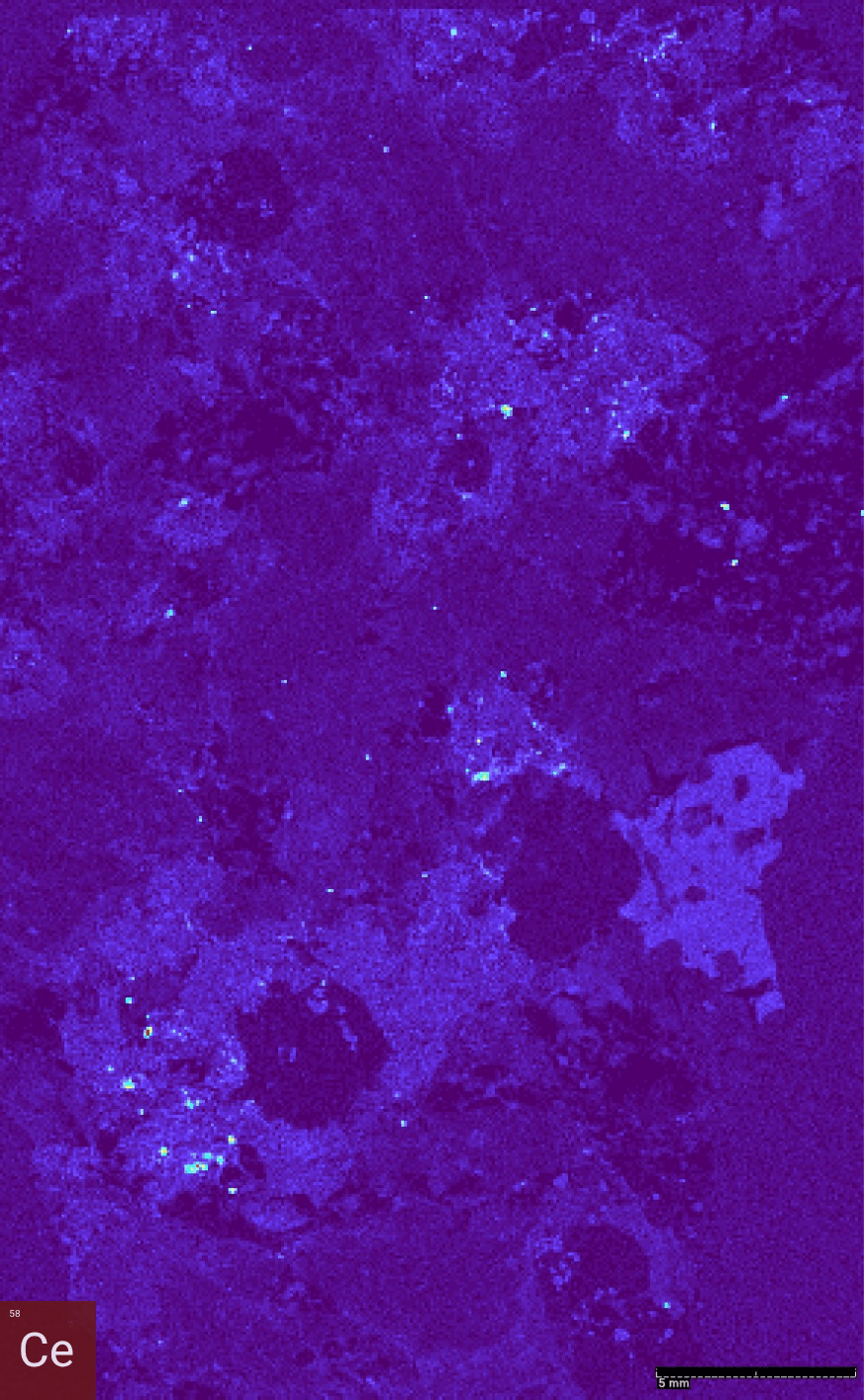

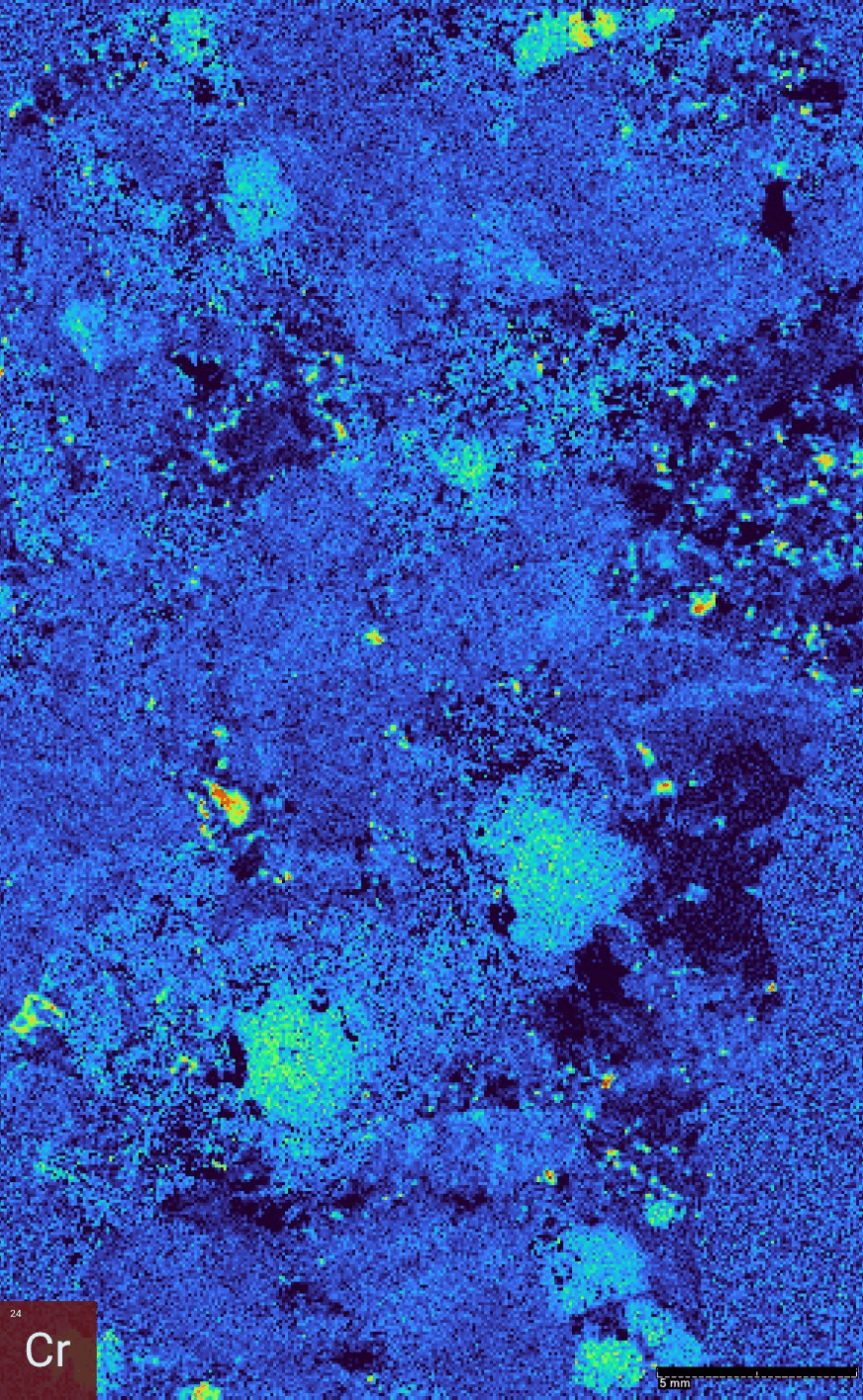

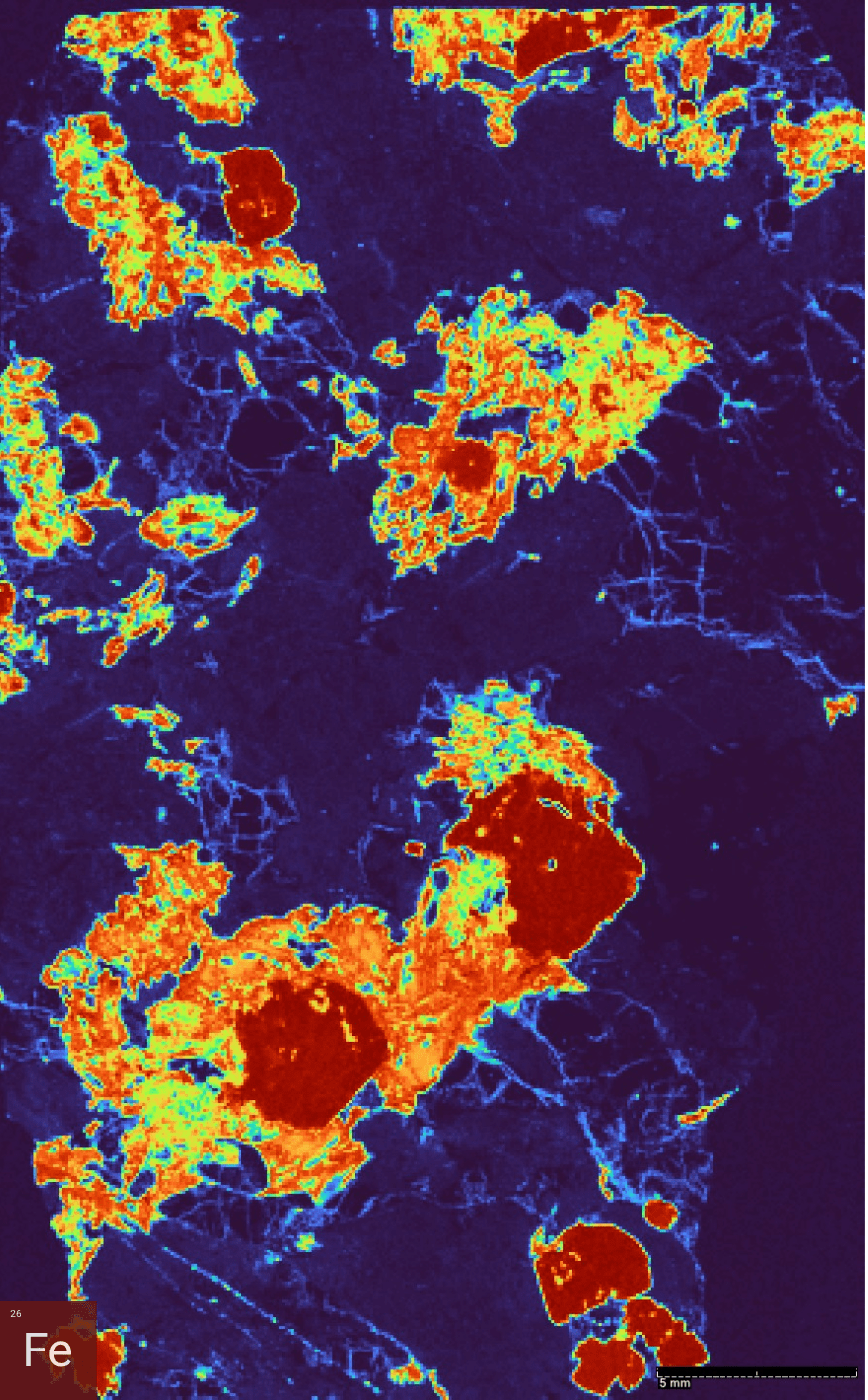

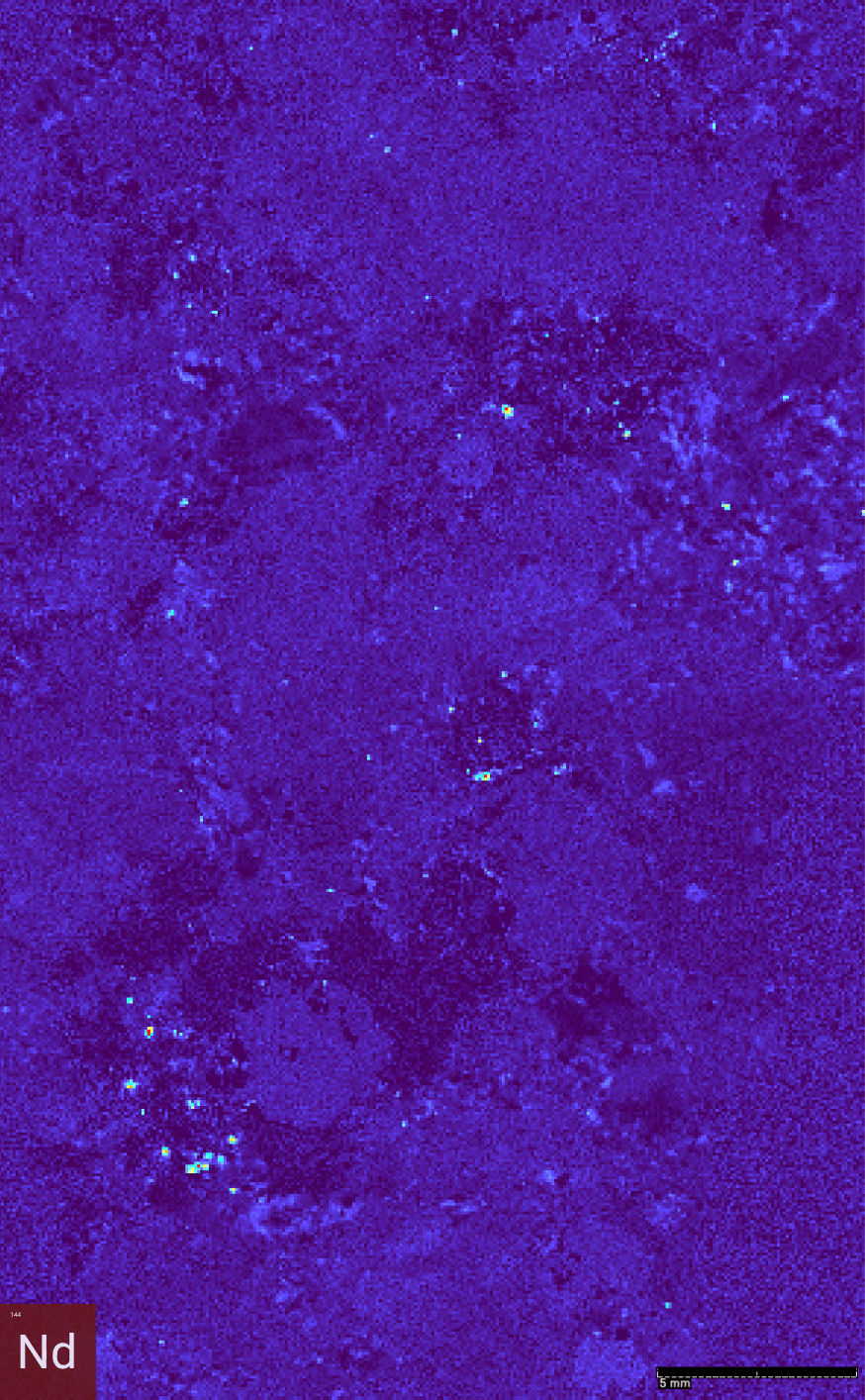

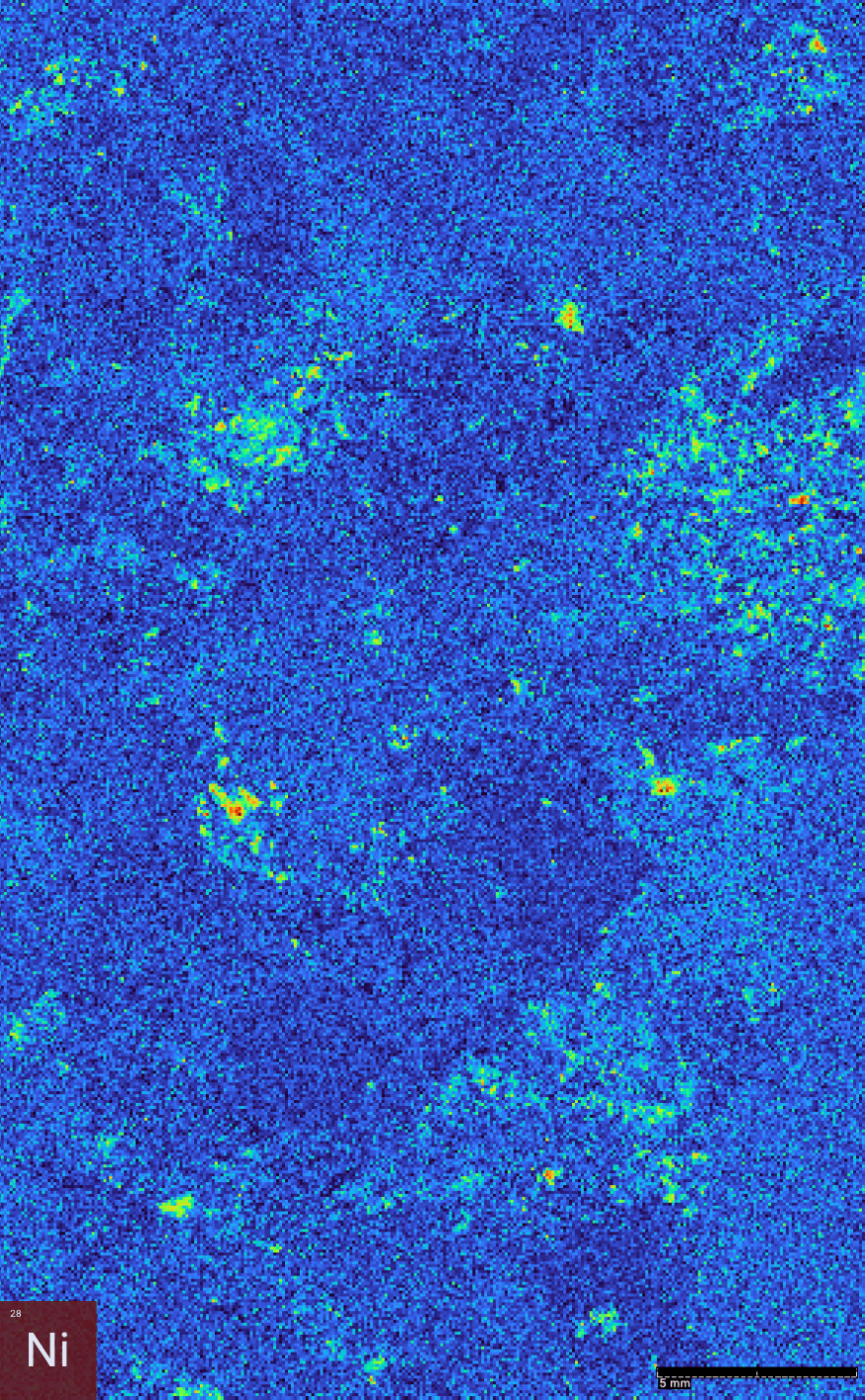

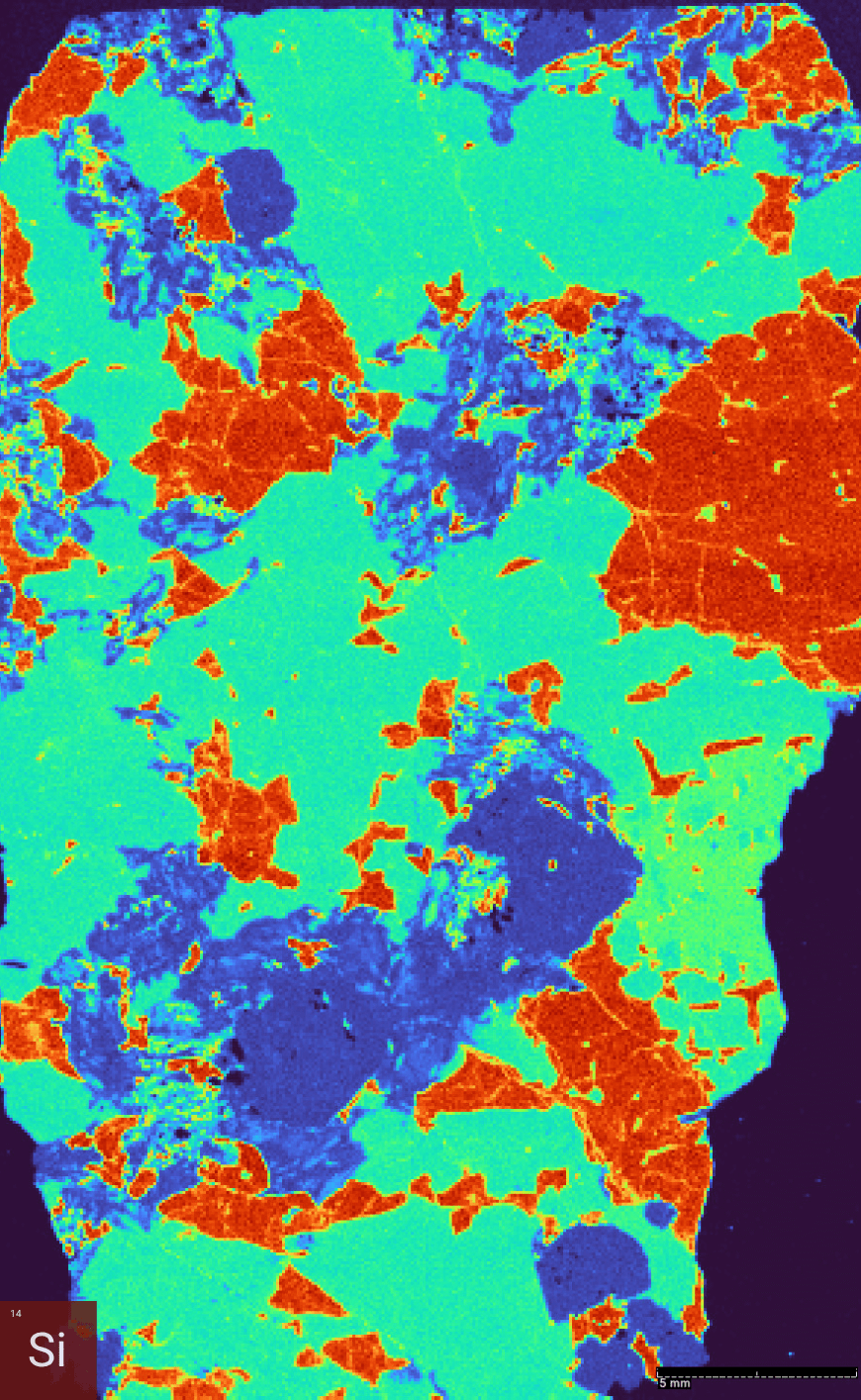

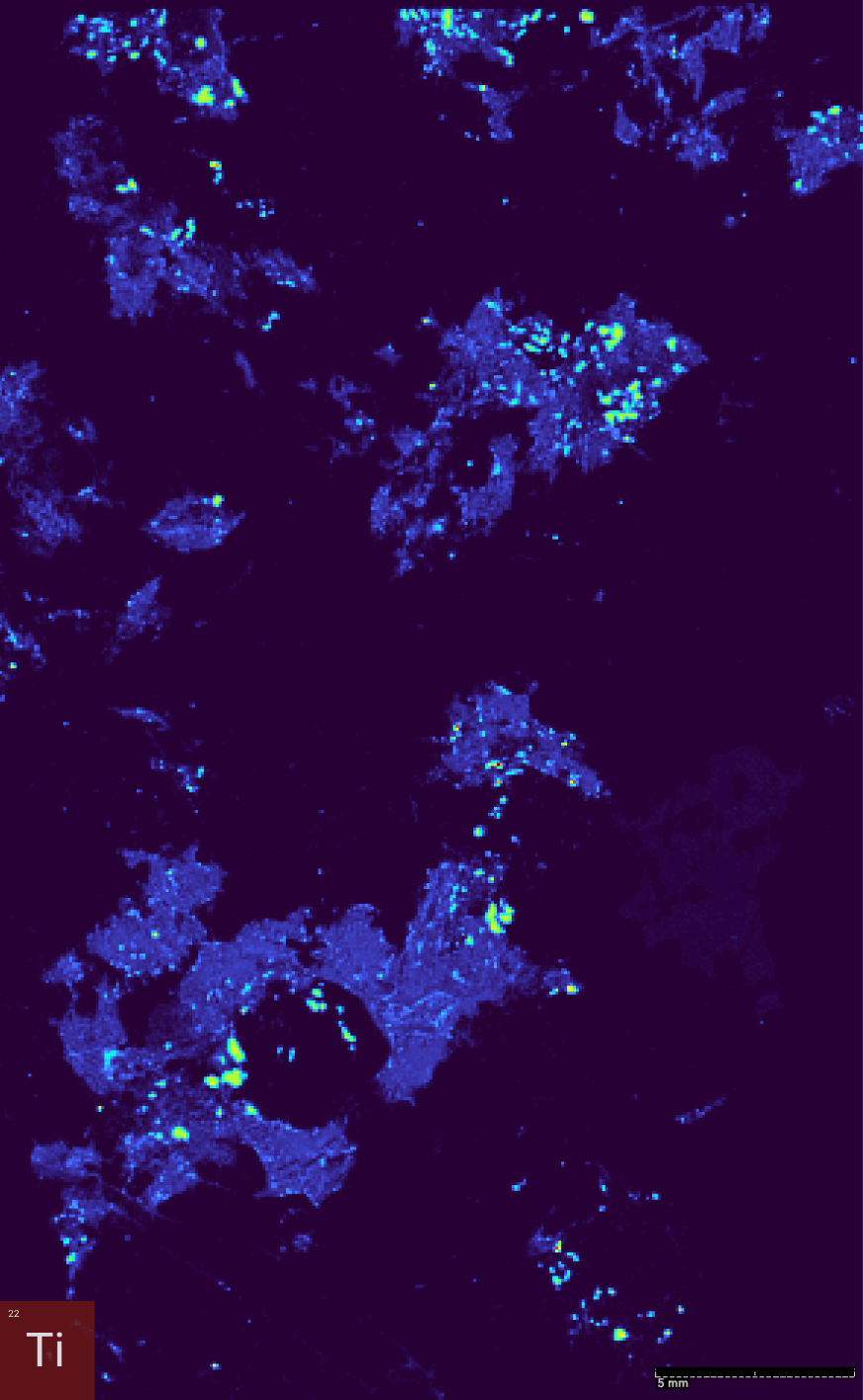

Figure 1. MicroXRF map thin section containing minerals like Monazite. Monazite is a key source of critical rare earth elements like neodymium and praseodymium, essential for electric vehicles and wind turbines. High-resolution microXRF imaging reveals the elemental zoning that guides smarter exploration and resource recovery.

The Atlas microXRF: A Precision Tool for a Materials-Critical Future

At IXRF Systems, our mission is to empower engineers and researchers with the most capable analytical tools available. Our Atlas microXRF system provides ultra-high spatial resolution (<10 µm) and broad elemental coverage (C to U), making it ideal for analyzing critical materials across:

-

Rare Earth Magnets (Nd, Pr, Dy, Tb, Ga, Fe)

-

Battery Components (Li, Co, Ni, Mn, Graphite)

-

Semiconductors (Si, SiC, GaN)

-

Recycled and Secondary Sources (e-waste, mine tailings, slag)

Whether you are mapping elemental distributions in ores, verifying gallium nitride wafers, or evaluating magnet degradation, the Atlas offers unmatched performance in resolution, speed, and flexibility.

Here’s how the Atlas microXRF supports the DOE’s strategic pillars

- Diversify & Expand Supply: Analyze raw materials and unconventional sources—like mine tailings or recycled electronics—to uncover alternative material streams.

- Develop Alternatives: Screen the performance of doped or substituted materials using elemental mapping to assess feasibility as replacements.

- Materials and Manufacturing Efficiency: Non-destructive and rapid, the Atlas reduces testing cycle time, enhances QA/QC, and supports advanced manufacturing R&D.

- Circular Economy: Accurately evaluate material purity and elemental distribution in recycled or remanufactured components—essential for sustainable reuse.

- Enabling Activities: Support R&D with robust quantitative microXRF elemental mapping data for theoretical models and machine-learning algorithms aimed at optimizing resource utilization.

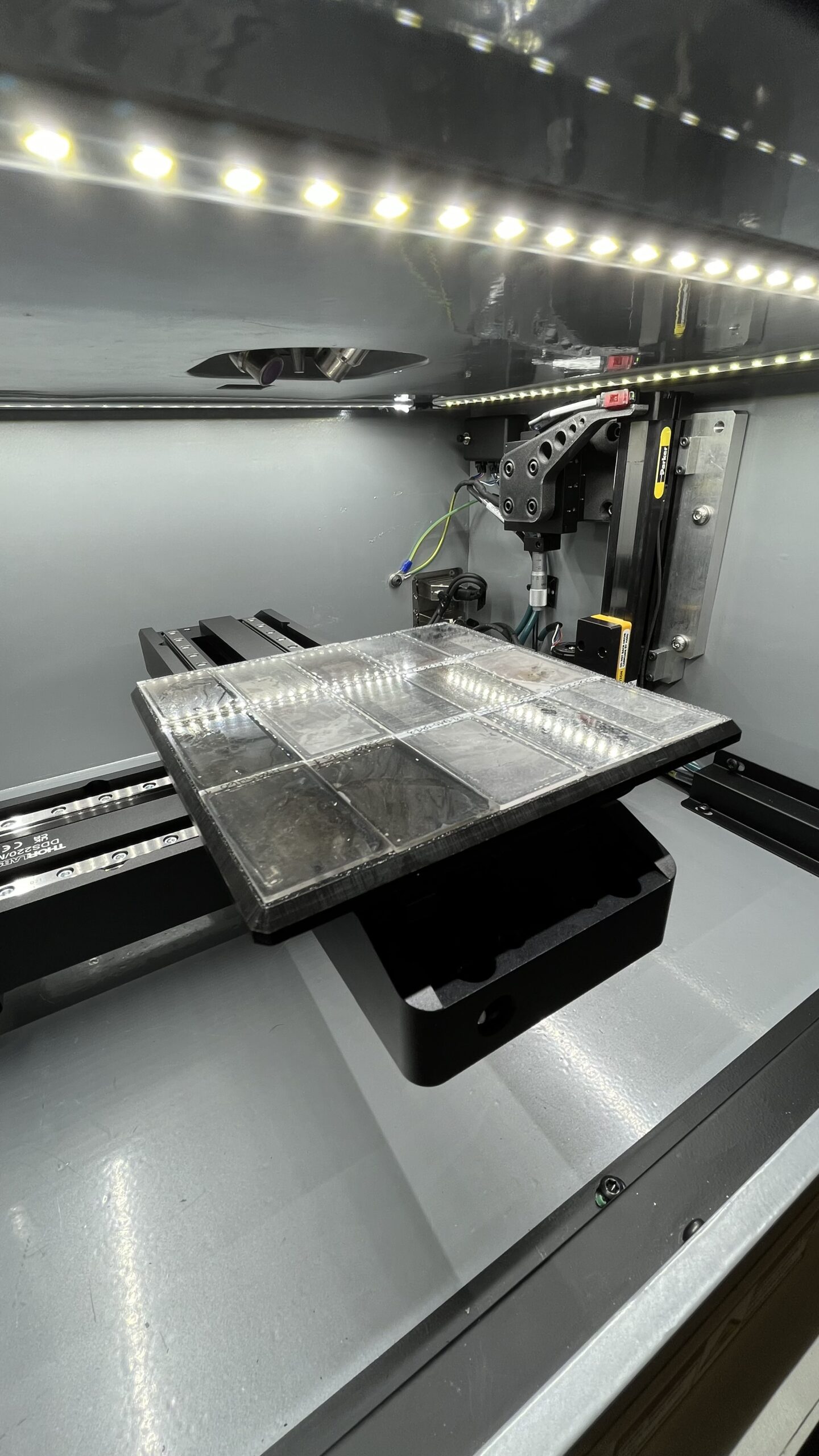

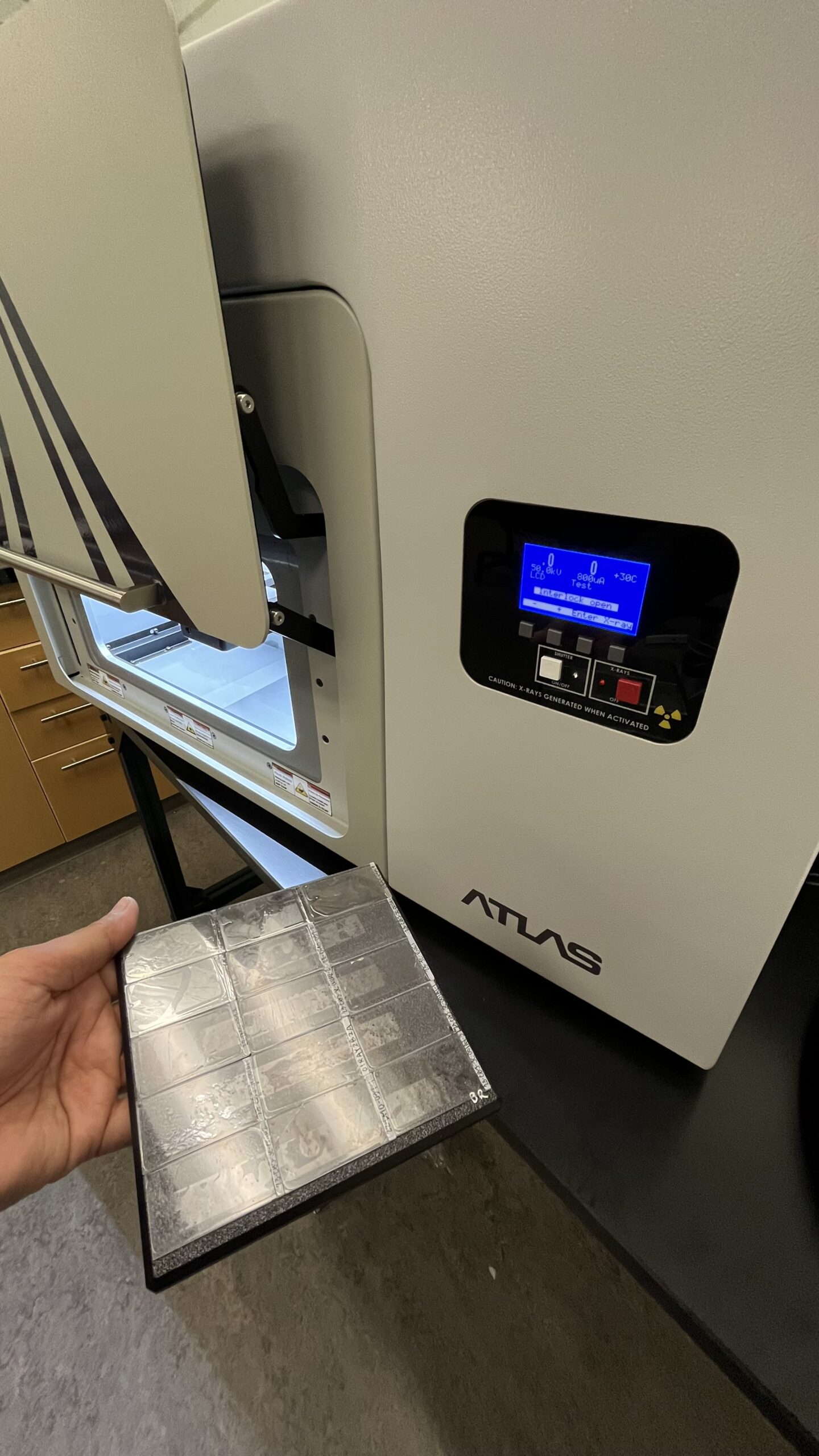

Figure 2. Atlas M microXRF set up for automated thin section analysis. High-resolution elemental maps help pinpoint critical materials at the micron scale.

A Platform Built for the Next Era

As demand for clean energy continues to grow, microXRF will play an increasingly crucial role not only in discovery but also in deployment. The modular design of the Atlas platform ensures that laboratories can scale their capabilities, from single-detector benchtop systems to multi-detector configurations for high-throughput industrial workflows.

With the largest chamber in its class, the most efficient X-ray optics, and unmatched flexibility, the Atlas microXRF system is designed to grow alongside your mission, whether in advanced R&D labs, battery recycling facilities, or rare earth mining operations.

Conclusion

The future of clean energy is material-intensive, and material intelligence starts with measurement. IXRF Systems is proud to provide tools that empower scientists and engineers to understand, optimize, and secure the materials necessary to power our planet.

To learn more about how the Atlas microXRF can accelerate your work with critical materials, contact us at ixrfsystems.com.