We live in an age where the omnipresence of electronic devices is undeniable. From smartphones and laptops to electric vehicles and renewable energy storage solutions, batteries are the lifelines of modern civilization. As technological innovations surge, so does the demand for improved performance, efficiency, and longevity in battery technology. Today, every small increment in a battery’s energy density or cycle life can significantly amplify a device’s potential or increase the range of an electric vehicle. With the world’s ever-growing hunger for energy storage solutions, there is an undeniable urgency to push the boundaries of current battery technology.

However, the traditional materials and chemistries we’ve come to rely upon, such as lithium-ion, have limitations. These limitations bring forth questions regarding resource availability, environmental impact, and performance ceilings. As a result, research in alternative materials is not just desirable—it’s imperative.

Exploring Alternative Materials: The Quest to Supercharge Batteries

To keep pace with the burgeoning demand, scientists and engineers worldwide are delving deep into the heart of materials previously unexplored for energy storage purposes. Emerging candidates, such as solid-state electrolytes, lithium-sulfur batteries, and multivalent ion systems, promise not just incremental but revolutionary advancements in battery technology.

However, while the promise of these materials is profound, realizing their potential demands a granular understanding at the atomic and molecular levels. As battery materials become more intricate and sophisticated, the tools used to study them need to match their complexity.

The Need for Advanced Research Tools: Enter MicroXRF Technology

As we strive to design the next generation of batteries, the role of sophisticated analytical instruments cannot be overemphasized. One such powerful tool making waves in battery research is micro X-ray fluorescence (microXRF) technology.

MicroXRF is a non-destructive analytical technique that provides elemental and chemical analysis of materials. Unlike traditional methods that offer bulk analysis, microXRF can target specific micro-regions of a sample, giving researchers a holistic understanding of their materials’ behaviors and properties.

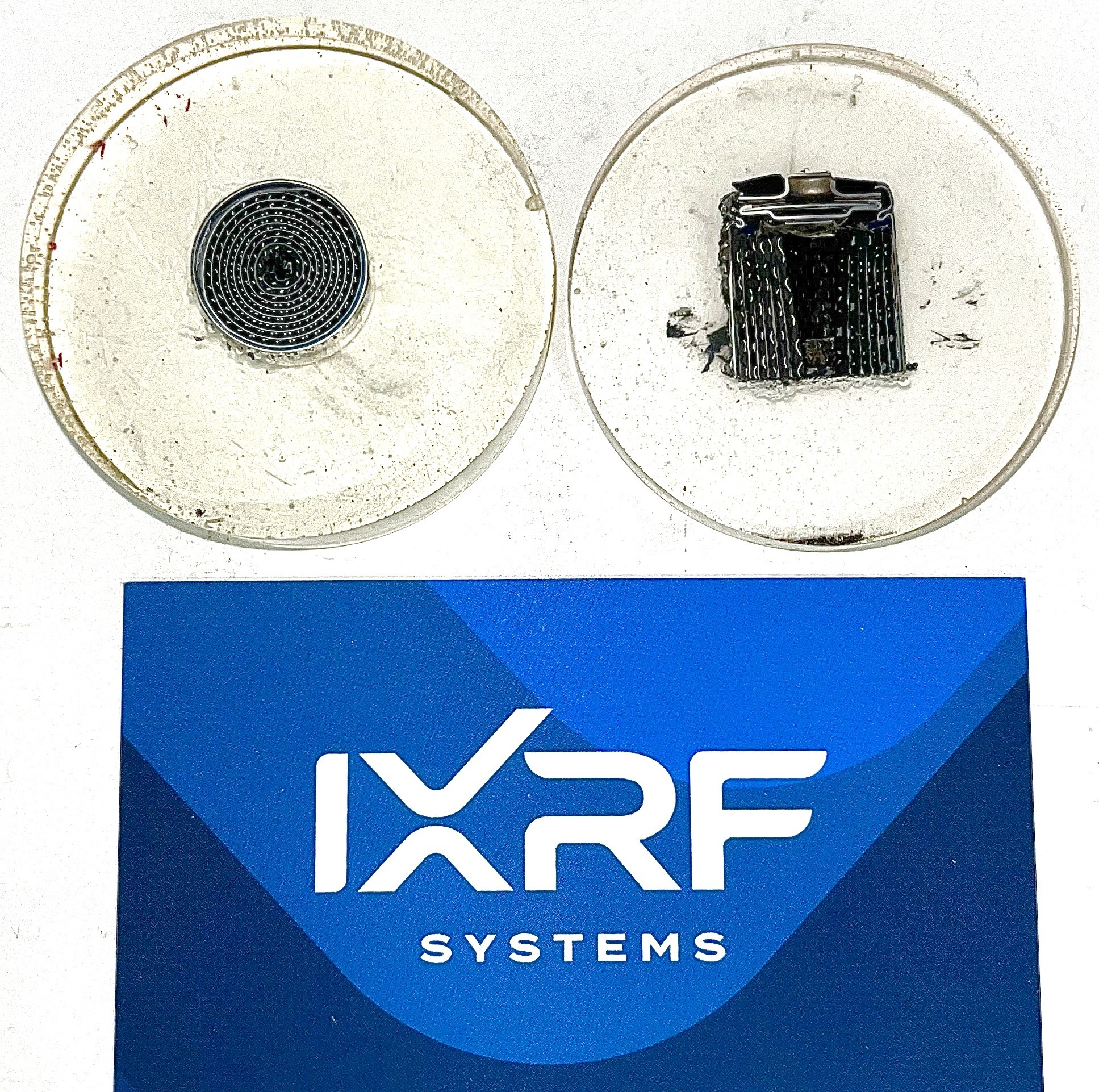

Figure 1: (1) Image of Li-Ion battery samples prepared both transversally and longitudinally, (2) Image of prepared Li-Ion battery samples inside the Atlas X microXRF.

A Deep Dive: How High Spatial Resolution MicroXRF Advances Battery Research

As internal battery materials are needed to get smaller and more intricate, MicroXRF with higher spatial resolution becomes more important. Benchtop microXRF instruments like the Atlas M, which provides an X-ray spot size as small as 5 µm, take this capability a notch higher. With the ability to focus on minute details, researchers can:

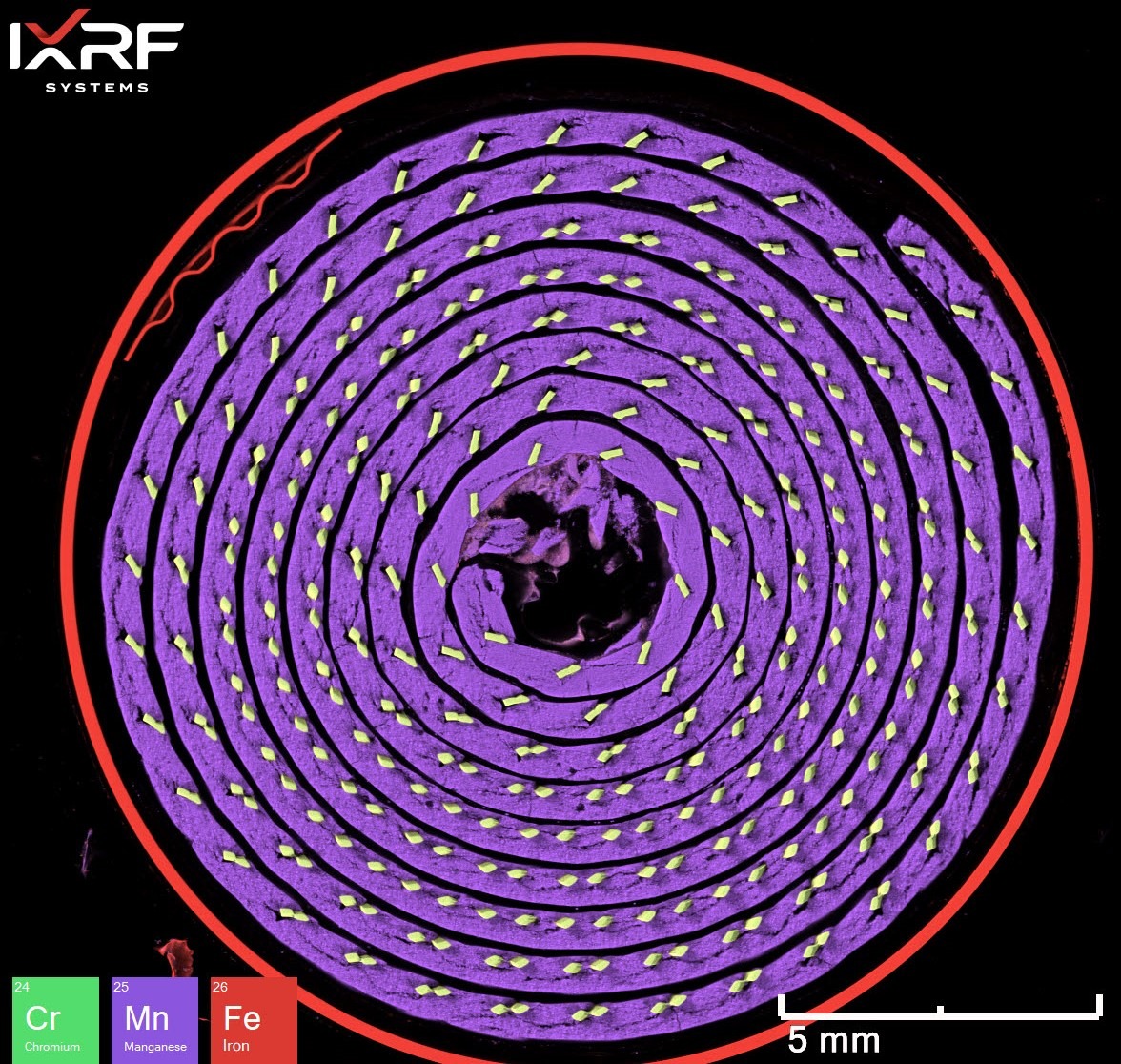

Study Interfaces with Precision

The interfaces between the anode, cathode, and electrolyte are critical regions in batteries. MicroXRF with high spatial resolution allows researchers to monitor elemental migrations, which can be pivotal in understanding failure mechanisms and enhancing battery longevity.

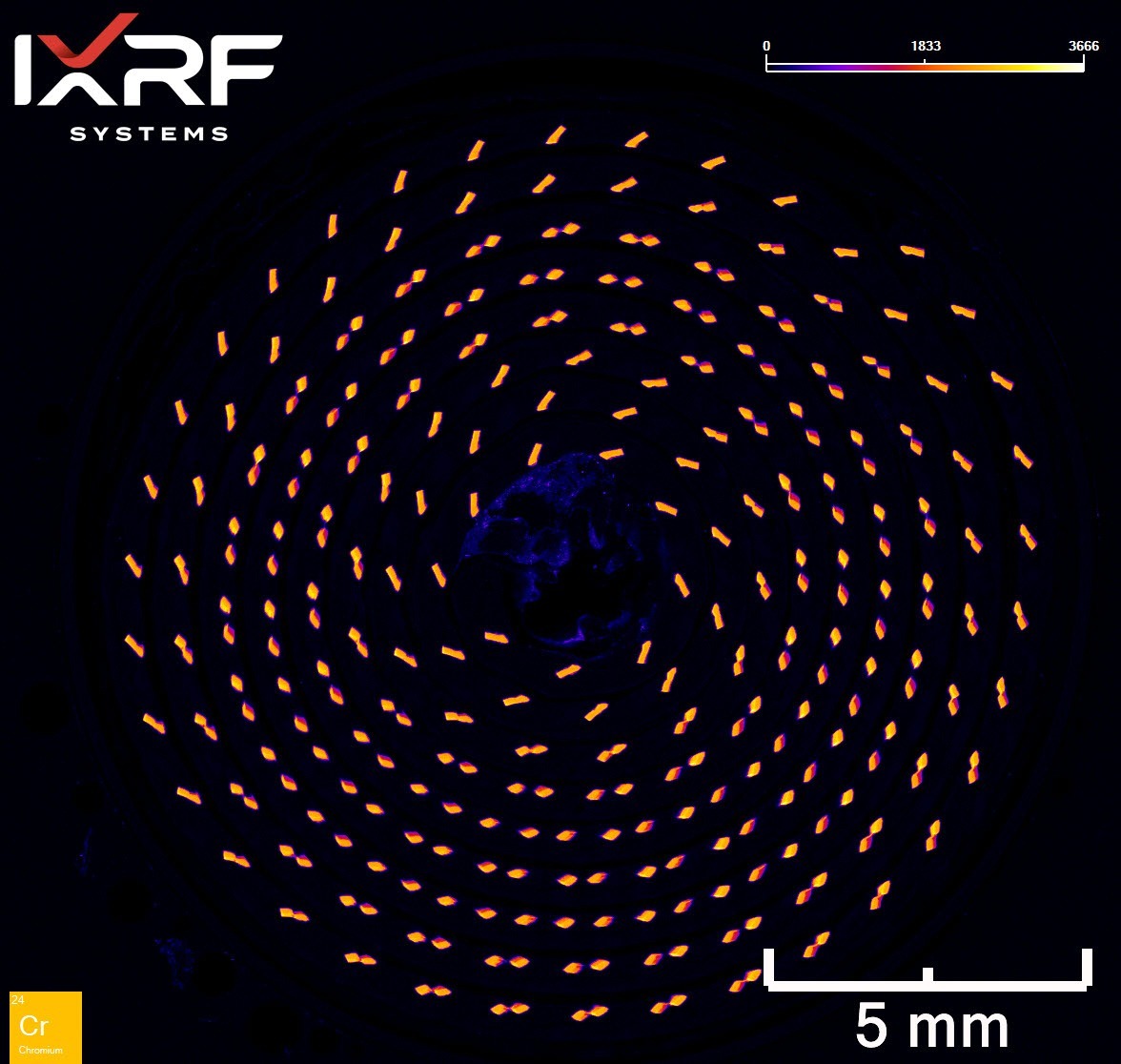

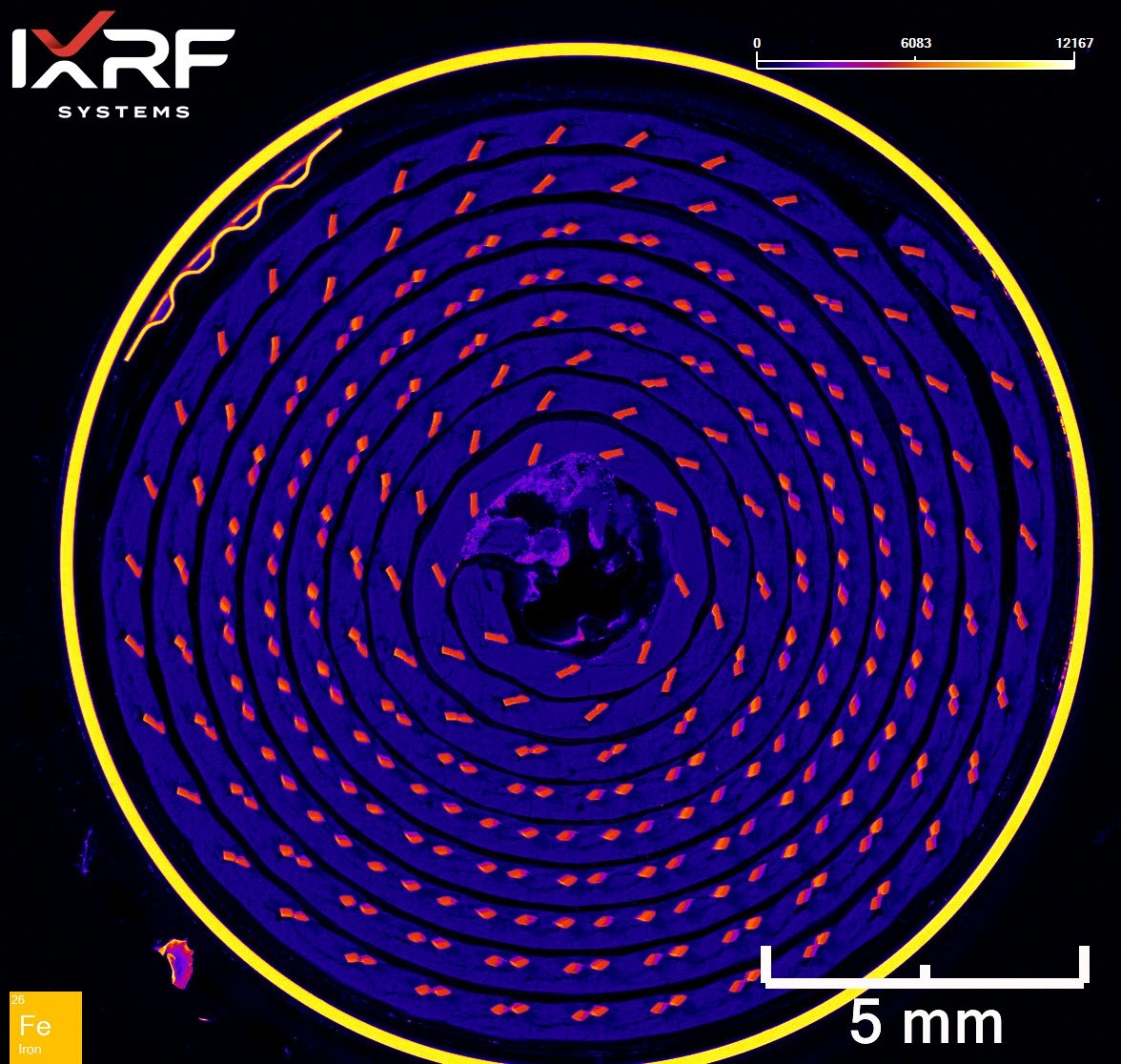

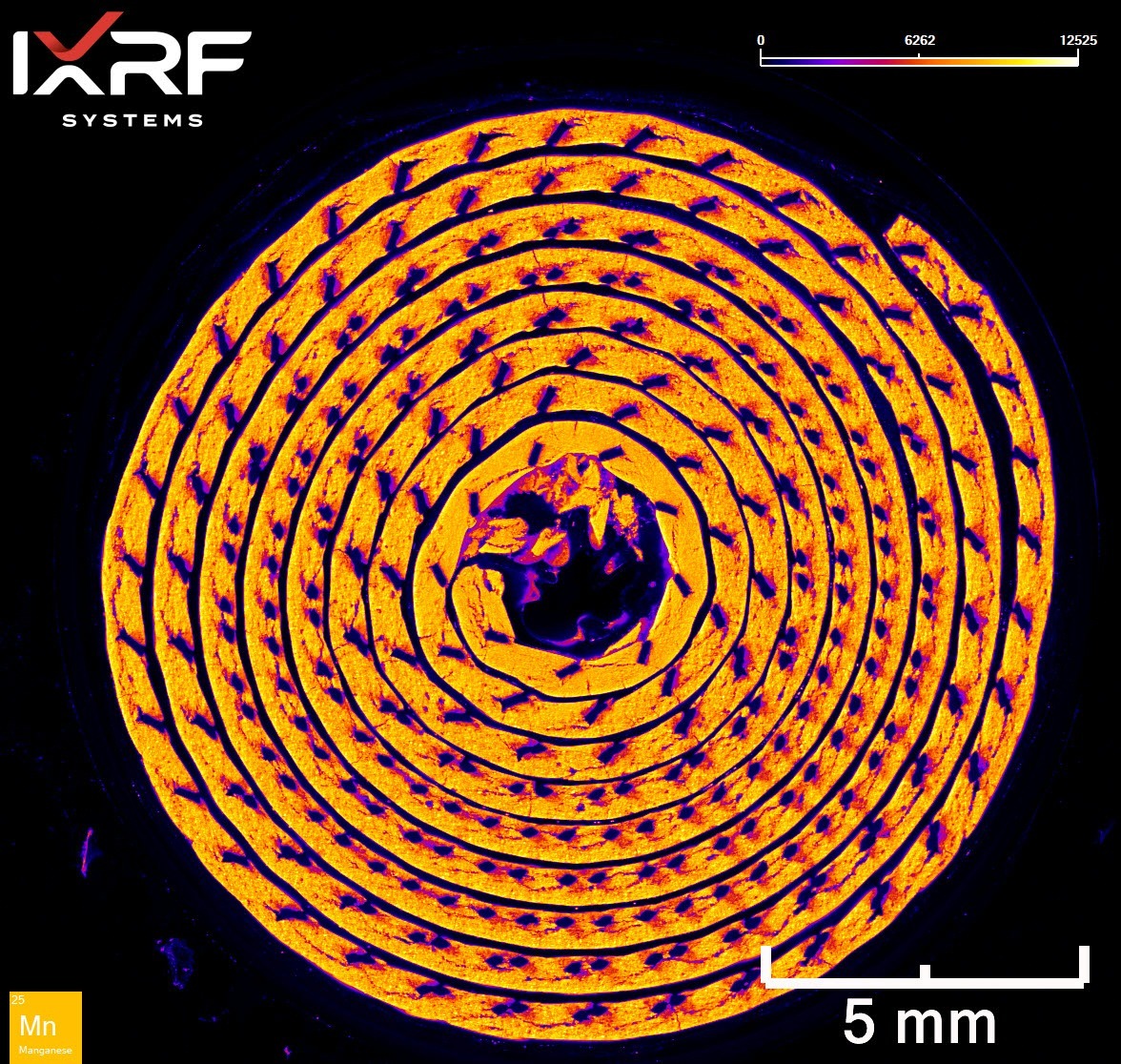

Figure 2: (image 1) MicroXRF overlay map of Li-Ion battery transversely cut, revealing detailed elemental distributions for chromium, manganese, and iron. (images 2-4) Maps are from the same sample used in image 1, except they are set to a fire color scale to help visualize the intensity difference to match the intensity legend. Maps were collected using a 5 μm spot and pixel size.

Map Elemental Distribution

As we incorporate novel materials into batteries, understanding their distribution becomes crucial. High spatial resolution microXRF can create detailed maps showcasing where specific elements such as lithium, cobalt, nickel, manganese, and other transition metals reside, providing insights into the material’s fundamental properties, homogeneity, and potential performance.

Detect Contaminants

Even minor impurities can severely affect a battery’s performance. With microXRF, researchers can spot and quantify these contaminants, ensuring the purity of the materials used.

Accelerate Research Cycles

Traditional research methods can be time-consuming. With the detailed insights provided by microXRF, researchers can rapidly iterate and refine their materials, speeding up the development of the next generation of batteries.

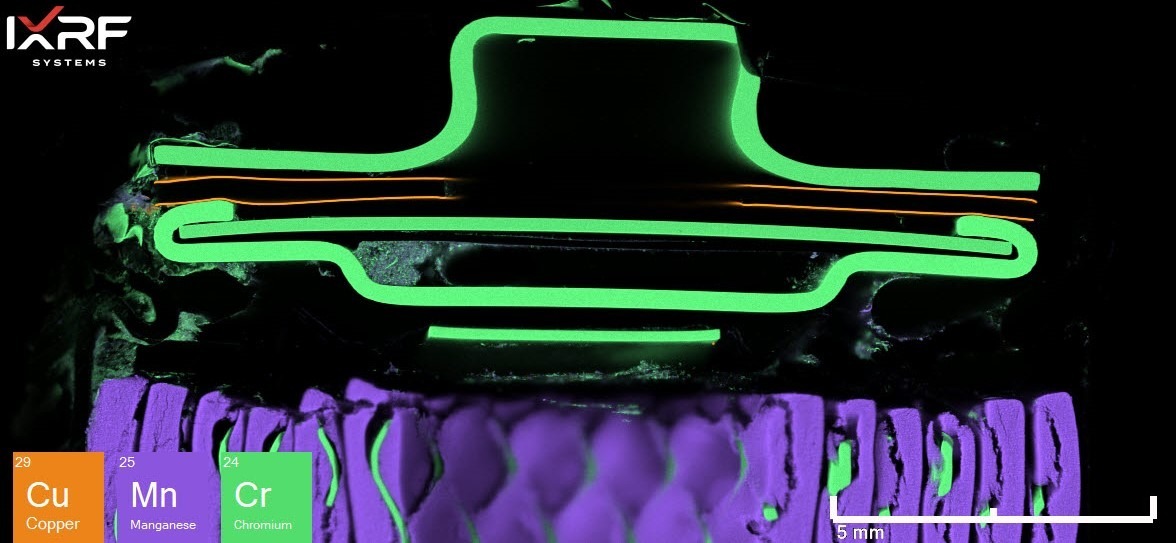

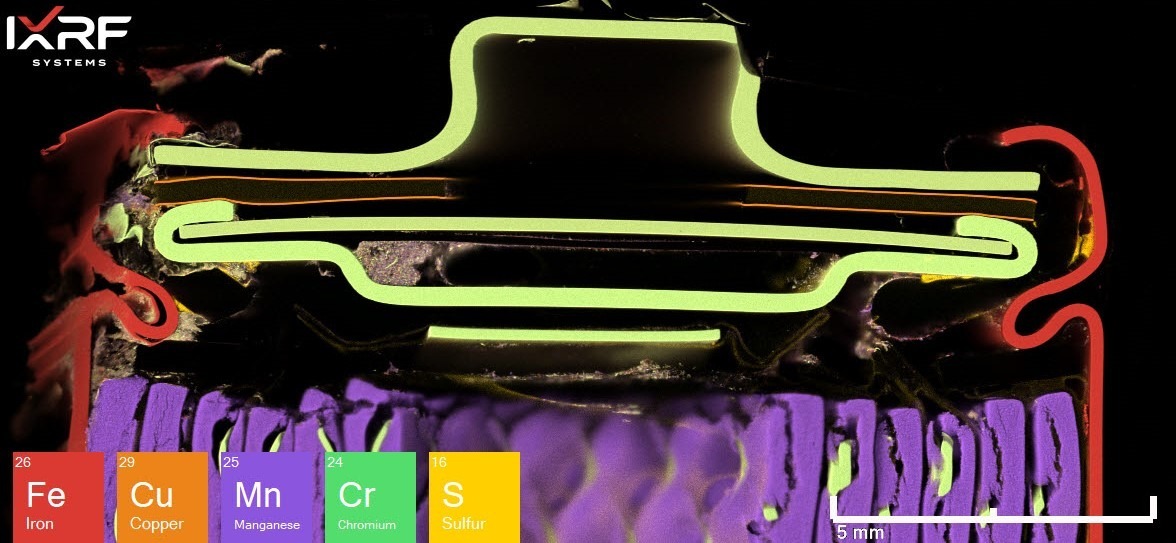

Figure 3: (1) MicroXRF overlay map of Li-Ion battery longitudinal cut, revealing detailed elemental distributions for copper, manganese, and chromium. (2) Same sample map as image 1, but with the additional elemental overlay of sulfur and iron included.

Characterize Battery Degradation and Failure Mechanisms

MicroXRF can be used to study the degradation and failure mechanisms of batteries. For example, it can be used to analyze the changes in elemental composition and distribution in battery components during cycling or aging processes, which can help identify the causes of battery degradation, such as metal dissolution, migration, or deposition. This information can be used to develop strategies to mitigate battery degradation and improve battery lifespan.

Investigation of Battery Safety Issues

MicroXRF can be used to investigate safety issues related to batteries and energy storage systems. For example, it can be used to analyze the distribution and concentration of elements in battery components after thermal runaway events or other safety incidents to understand the causes of battery failures and improve battery safety.

Conclusion

The world’s pressing need for advanced batteries is clear. To meet this demand, our research approach must be equally groundbreaking. By leveraging tools like high spatial resolution microXRF, we are ensuring a brighter future for battery technology and a world that increasingly relies on it. With continued advancements, the horizons of what batteries can achieve will expand, driving progress and innovation in myriad domains.

Enhance your battery research with the insights provided by microXRF. For a detailed understanding of materials and their interactions, microXRF offers a reliable solution. Learn more about its capabilities and see how it can contribute to your research objectives.

IXRF Systems is a leading provider of X-ray fluorescence instrumentation. With our advanced analytical solutions, we are committed to supporting research, quality control, and educational endeavors across various industries. Click here to contact us today to get a deeper understanding of how our technology can be a valuable addition to your analytical toolkit.