The intrinsic properties of polymers, which make them a linchpin in countless applications, can be compromised by the invasion of foreign materials. Whether these foreign entities are an unintentional byproduct of the manufacturing process or an external contamination, their presence can drastically alter a polymer’s performance. This article dives deep into the world of embedded contaminants in polymers and spotlights the role of high spatial resolution microXRF as a detective tool in this challenging forensic endeavor.

The Hidden Threat: Foreign Material in Polymers

Embedded contaminants in polymers are insidious. Often invisible to the naked eye, these intruders can range from minuscule metal fragments, residual catalysts, and degraded polymer chains to foreign particles introduced during processing. Their presence can:

- Alter Physical Properties: Introduce weak points, leading to reduced tensile strength or making the polymer prone to cracks.

- Interfere with Processing: Cause issues during molding, extrusion, or other fabrication processes.

- Create Safety Hazards: These foreign materials can introduce health risks in specific applications, like medical devices or food packaging.

The Power of MicroXRF

MicroXRF (micro X-ray fluorescence), like the Atlas M from IXRF Systems, emerges as a hero to detect and analyze such intruders in the analytical world. Here’s a brief on its operation:

- A focused X-ray beam, as small as 5 µm, targets the sample.

- When irradiated, the elements in the sample emit their unique X-ray fluorescence.

- This emitted radiation is captured and scrutinized to decipher and quantify the elements present.

Key Features of MicroXRF

- Precision: Offers high spatial resolution, detecting contaminants down to low micrometer levels.

- Depth Perception: Can provide a depth profile of elements, determining if contaminants are superficial or deeply embedded.

- Safe & Sound: It’s a non-destructive method, ensuring the sample remains unharmed.

Figure 1: (Left) Atlas M microXRF, (Right) inside view of four detectors and one 5-micron polycapillary source on Atlas M microXRF.

MicroXRF as the Polymer Detective

In the quest to unmask hidden contaminants in polymers, microXRF comes equipped with distinct advantages:

- Comprehensive Scanning: It can swiftly scan larger areas, identifying potential contamination hotspots.

- Versatility: It doesn’t discriminate; whether the polymer is a thermoset, thermoplastic, elastomer, or fiber, microXRF is up for the task.

- Diverse Detection: From metal fragments and inorganic fillers to different elements, microXRF can identify a wide range of foreign materials.

Case Studies: MicroXRF in Action

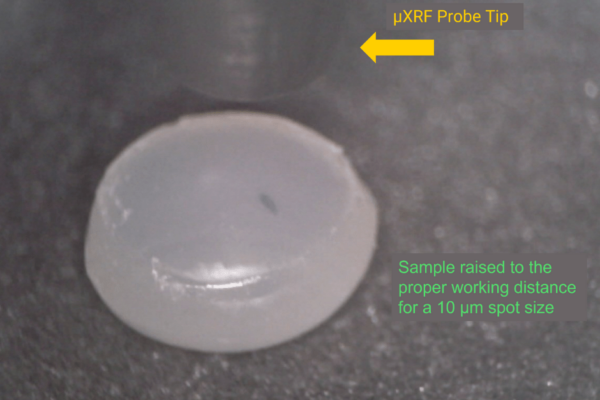

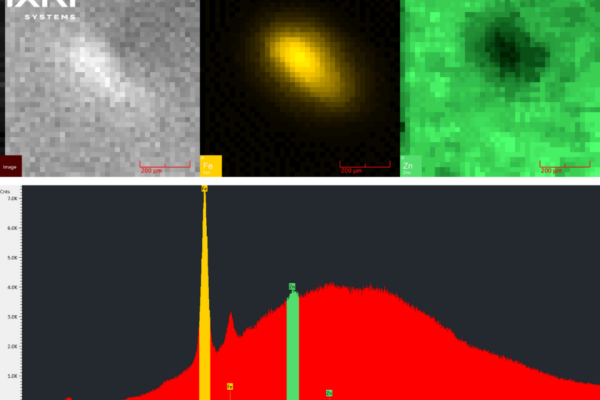

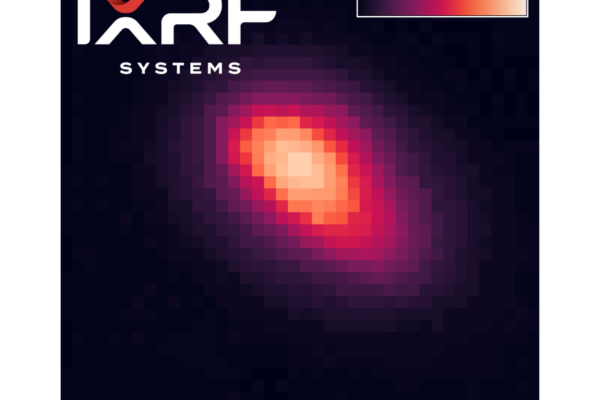

Figure 2: (1) Image of polymer bead sample on stage with sample in focus, (2) 2-D XRF chemical maps for iron (Fe) and zinc (Zn) of foreign material embedded in polymer bead along with Sum spectrum, (3) chemical map of iron (Fe) map in rocket thermal view.

Medical Implants

In a recent study, microXRF was employed to detect trace metal contaminants in polymer-based medical implants, ensuring biocompatibility and patient safety.

Packaging Films

A leading packaging company used microXRF to trace the source of sporadic impurities in their polymer films, causing aesthetic and functional issues.

Automotive Polymers

To solve the mystery of premature failures in specific plastic components, an automotive company turned to microXRF, revealing hidden metallic contaminants affecting the parts’ integrity.

Conclusion

In the vast universe of polymers, the infiltration of foreign materials can spell disaster for product performance, safety, and longevity. MicroXRF serves as an invaluable tool, illuminating the unseen and ensuring that polymers are as pure as they promise to be. As industries evolve and the demand for polymer purity intensifies, the prowess of microXRF will only become more pronounced, guarding the integrity of polymers and the trust of those who rely on them.

Further Your Knowledge in Polymer Analysis

Understanding the intricacies of polymers and the potential challenges of foreign contaminants is vital for many industries. With tools like microXRF at our disposal, a more comprehensive and accurate analysis is within reach. Are you interested in enhancing the quality and reliability of materials in your field? Consider delving deeper into the capabilities of microXRF. Stay informed, make informed decisions, and elevate your understanding of polymer purity.

IXRF Systems is a leading provider of X-ray fluorescence instrumentation. With our advanced analytical solutions, we are committed to supporting research, quality control, and educational endeavors across various industries. Click here to contact us today to get a deeper understanding of how our technology can be a valuable addition to your analytical toolkit.